Composite sandwich heat-preservation plate with bridge cut-off heat insulation strip and manufacturing method of composite sandwich heat-preservation plate

A thermal insulation board and sandwich technology, which is applied in thermal insulation, building components, buildings, etc., can solve problems such as poor adhesion of thermal insulation materials, influence of thermal insulation performance of walls, and fire hazards, and achieve accurate assembly dimensions, low cost, and on-site fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the solution and technical features of the present invention, as well as the object and effect of the present invention easy to understand, the present invention will be further elaborated and described below in conjunction with the accompanying drawings and through the following specific embodiments.

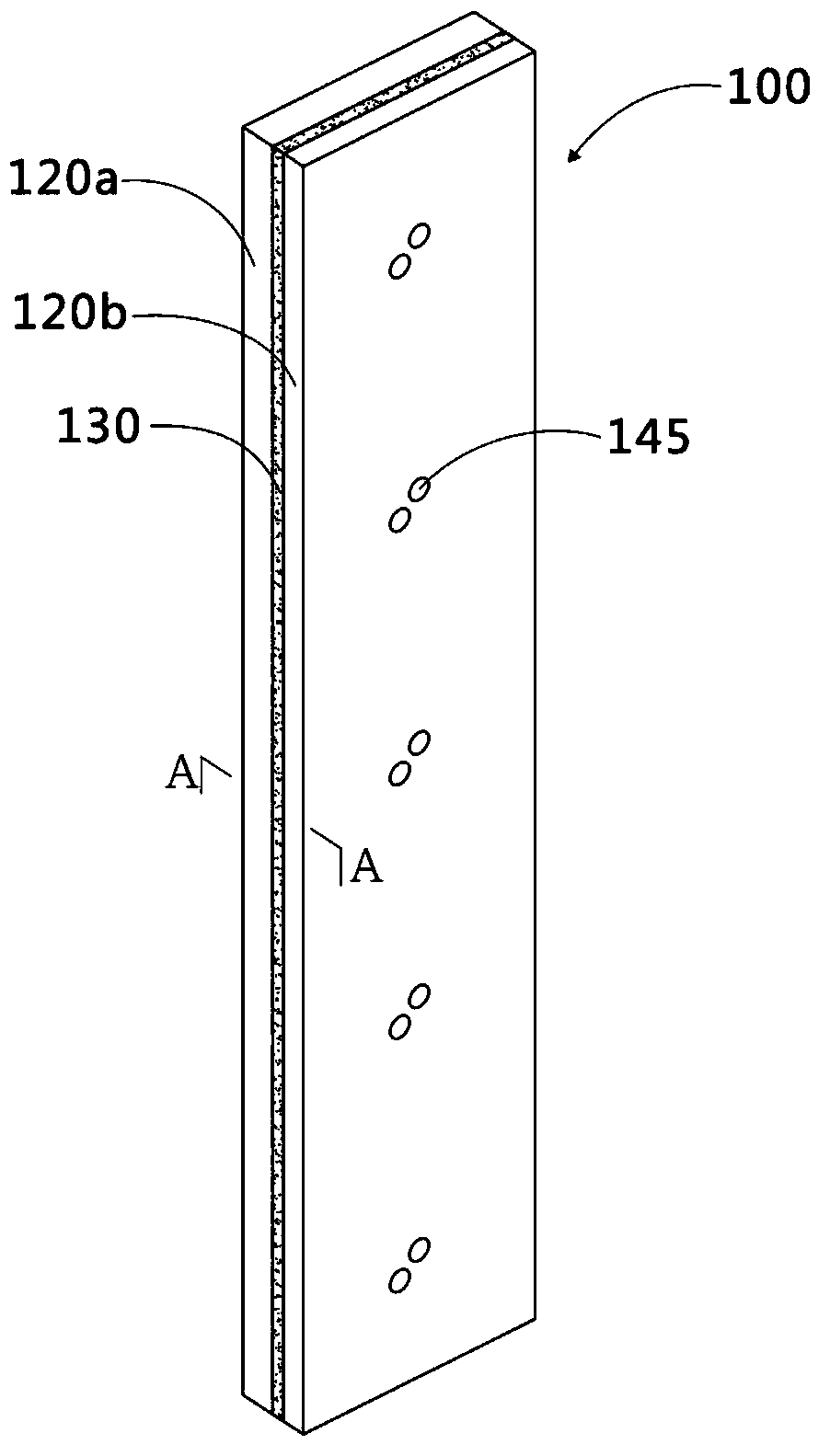

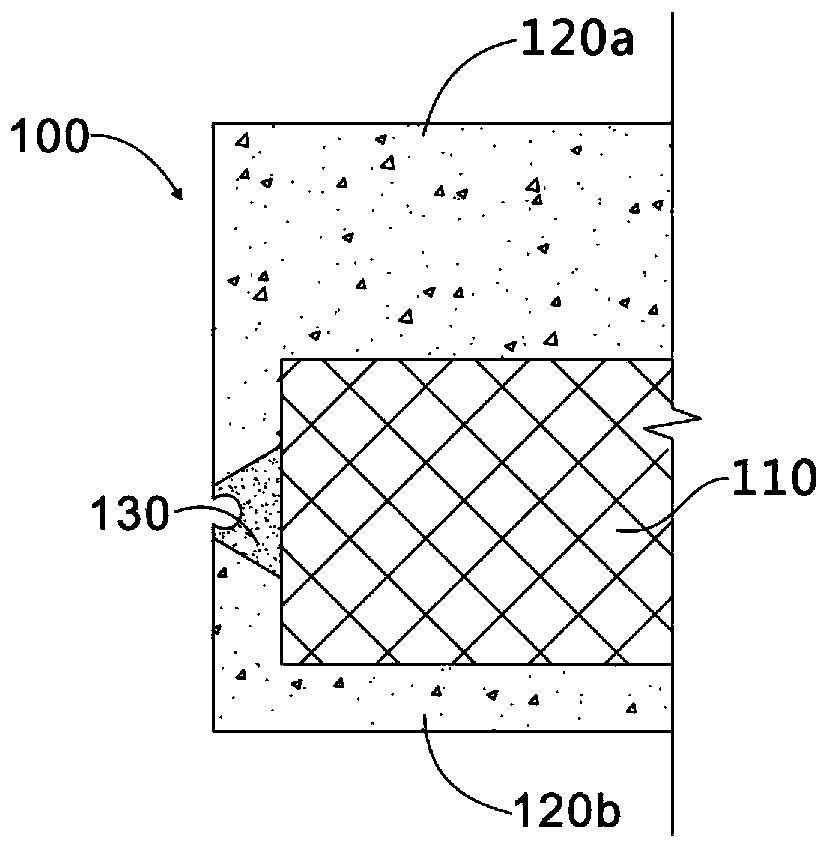

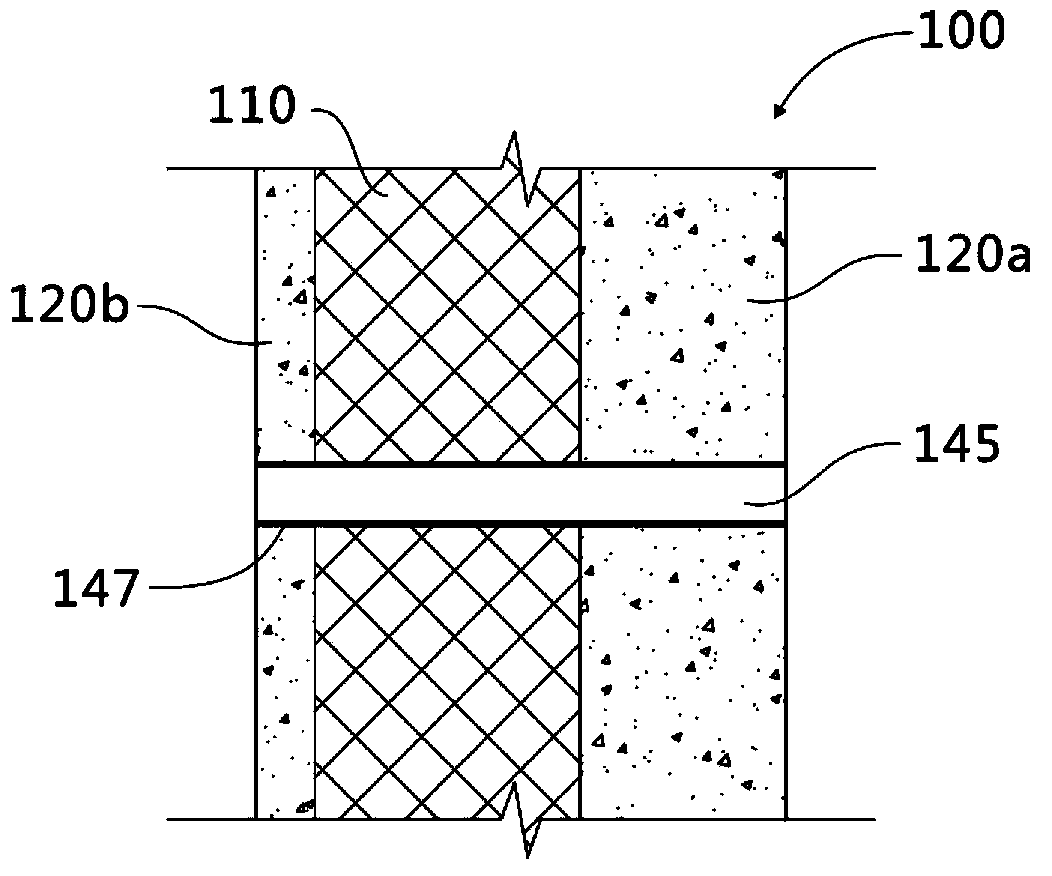

[0028] like Figure 1A and 1B As shown, the composite sandwich insulation board (100) with a bridge-breaking insulation strip includes: an insulation layer (110), which contains insulation materials; surface layers (120a, 120b), which are reinforced concrete materials and are set to be wrapped in Both sides and surroundings of the thermal insulation layer; and bridge-breaking thermal insulation strips (130), which are arranged around the thermal insulation board to avoid thermal bridges; wherein, between the surface layers (120a, 120b) and the thermal insulation layer ( 110) is preset with a plurality of cross-arranged perforations (145) (such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com