High pressure common rail system control method and device

A technology of a high-pressure common rail system and a control method, which is applied to electrical control, engine control, fuel injection control, etc., can solve problems such as the failure of the engine to work normally and the inability of the high-pressure common rail system to achieve effective control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

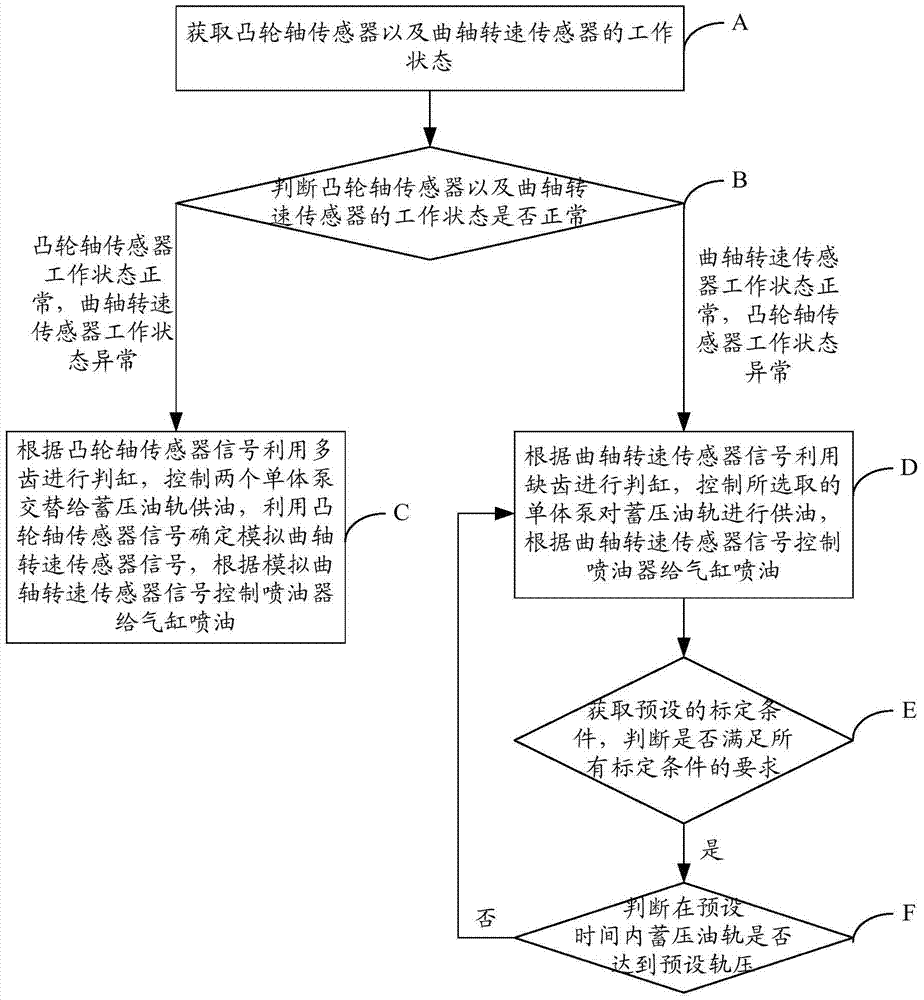

[0054] figure 1 It is a flow chart of Embodiment 1 of a high-pressure common rail system control method of the present invention, and the method includes:

[0055] Step A: Obtain the working status of the camshaft sensor and the crankshaft speed sensor.

[0056] The control system of the high-pressure common rail system is connected with the camshaft sensor and the crankshaft speed sensor. When it is necessary to inject fuel to the cylinder of the engine of the vehicle, the working status of the camshaft sensor and the crankshaft speed sensor is obtained.

[0057] When the camshaft sensor is working normally, the high pressure common rail system can obtain the sensing signal of the camshaft sensor, and the high pressure common rail system can control the two unit pumps to alternately supply oil to the accumulator rail according to the signal of the camshaft sensor.

[0058] The engine has 6 cylinders, and the camshaft has 7 teeth in total. Among them, one cylinder corresponds...

Embodiment 2

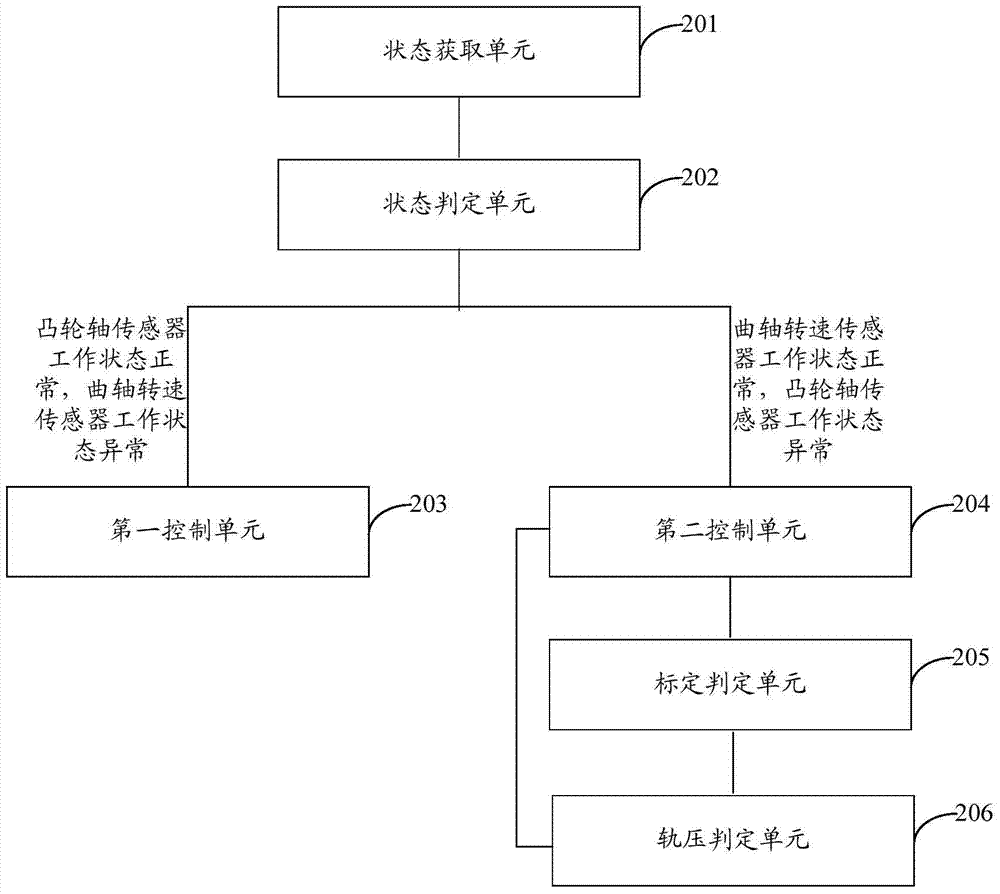

[0091] figure 2 It is a structural schematic diagram of Embodiment 2 of a high-pressure common rail system control device of the present invention, which is a device corresponding to the method protected by Embodiment 1. The device includes:

[0092] The state obtaining unit 201 is used to obtain the working states of the camshaft sensor and the crankshaft speed sensor.

[0093] State judging unit 202, is used for judging whether the working state of camshaft sensor and crankshaft speed sensor is normal, when the working state of camshaft sensor is normal, when the working state of crankshaft speed sensor is abnormal, enter the first control unit 203; When the working state of crankshaft speed sensor If it is normal, if the camshaft sensor is abnormal, enter the second control unit 204 .

[0094] The first control unit 203 is used to judge the cylinder by using multiple teeth according to the camshaft sensor signal, control the two unit pumps to alternately supply oil to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com