Heated brick bed type floor heating structure

A floor heating and heated kang technology, applied in the field of heated kang floor heating structure, can solve the problems of uneven heat dissipation, low thermal efficiency, short heat retention time, etc., and achieve the effect of simple structure, high thermal efficiency and comfortable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

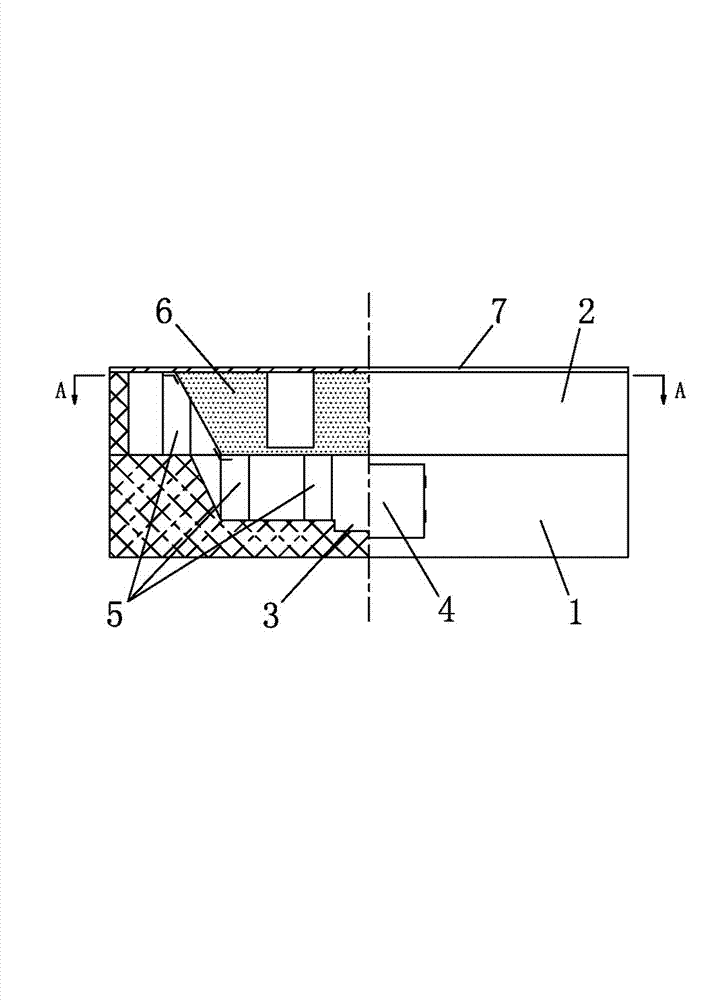

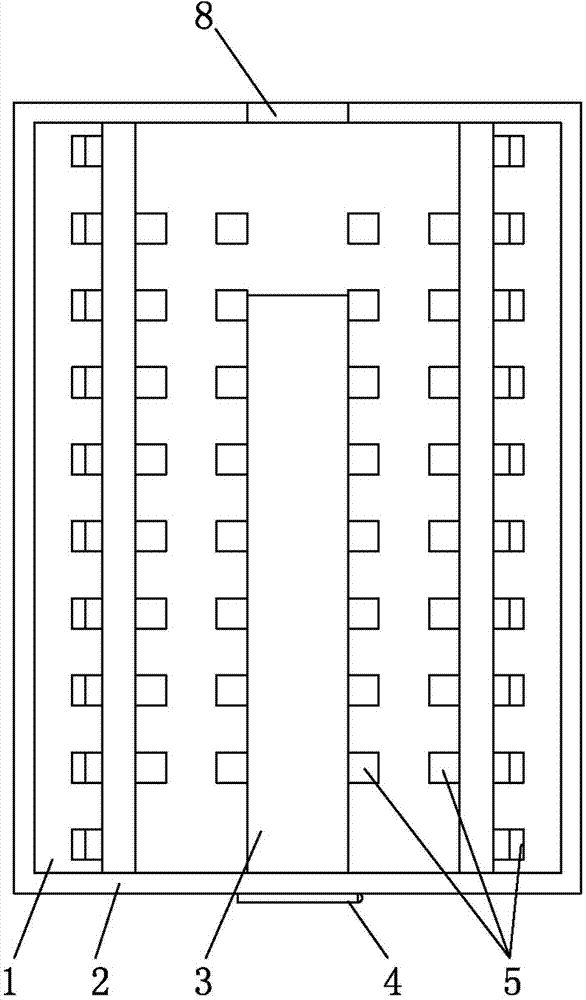

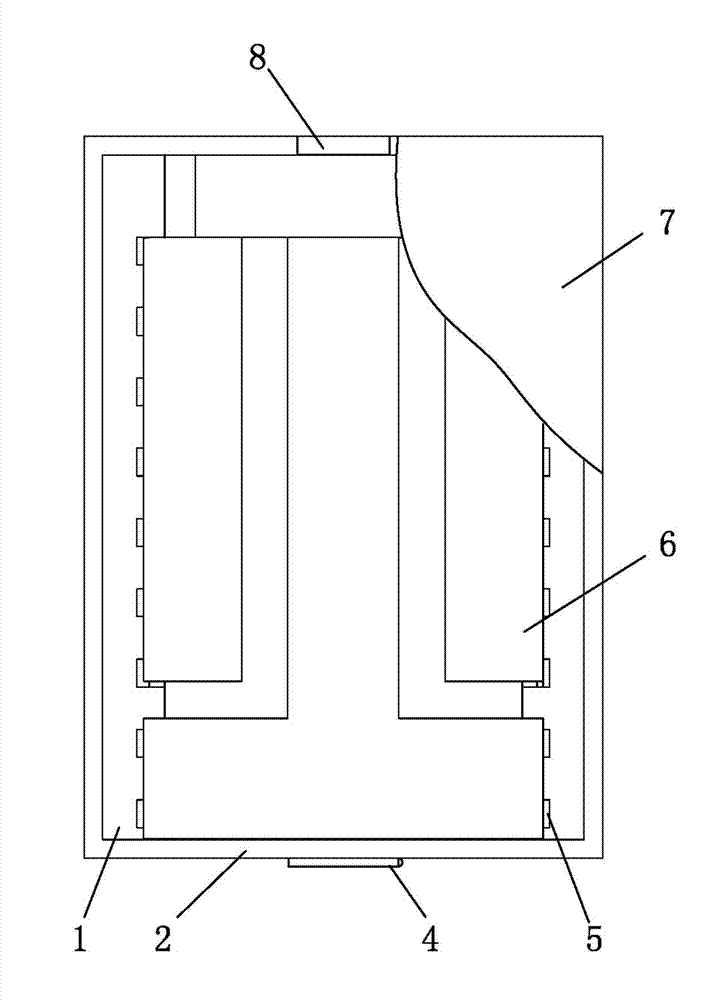

[0014] The specific embodiment of the present invention is described in conjunction with accompanying drawing:

[0015] as attached figure 1 , attached figure 2 And attached image 3 , the kang type floor heating structure has a base layer 1 and surrounding supporting walls 2 placed on the base layer 1, the base layer 1 and surrounding supporting walls 2 are suitable for forming with concrete with good thermal insulation performance, which can be formed separately or integrally. . As in the embodiment of the accompanying drawings, the top of the base layer 1 is designed in the shape of a longitudinal trapezoidal groove, which is symmetrical to the left and right, and a longitudinal groove 3 is arranged in the center of the upper surface of the base layer 1, and the longitudinal groove 3 is arranged as a rectangular cross-section groove. The longitudinal groove 3 constitutes the lower part of the combustion chamber. The front wall of the supporting wall 2 around is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com