Experiment device for recycling ammonia in LED (light emitting diode) mixed waste gas by compression refrigeration method and verifying method of experiment device

A technology of freezing method and exhaust gas, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as delay in recovery plan, failure of investment in recycling exhaust gas, etc., and achieve the effect of improving design accuracy, scientific and real data, and fast experimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

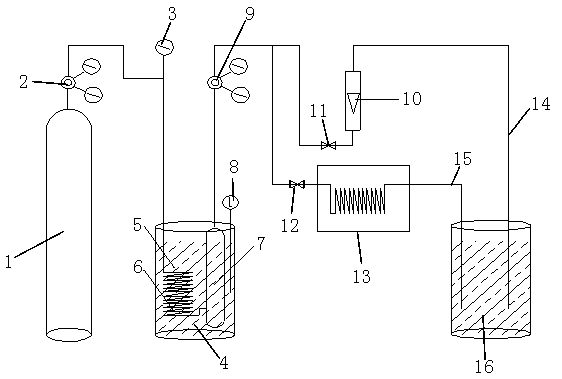

[0025] This embodiment is an experimental device and verification method for recycling ammonia in LED exhaust gas by compression freezing method, which includes: mixed standard gas cylinder (1), pressure reducing and regulating valve group, pressure gauge (3), low temperature Refrigerant container (4), cryogenic refrigerant (5), screw-type cryogenic tube set (6), gas-liquid separator (7), thermometer (8), gas flow meter (10), pressure regulating valve, gas chromatograph Instrument (13), waste gas neutralization bucket (16).

[0026] like figure 1 As shown, the mixed standard gas cylinder (1) is configured by mixing nitrogen, hydrogen, and ammonia in proportion to replace the compressed high-pressure gas cylinder used in the experiment, with a maximum pressure of 20MPa. The pressure valve group I (2) is connected, the pressure reducing and regulating valve group I (2) is connected with the screw-type freezing tube group (6), the screw-type freezing tube group (6) is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com