Ultra-high performance liquid chromatogram detection method for terlipressin and impurities thereof

A terlipressin and ultra-high performance liquid phase technology, which is applied in the field of ultra-high performance liquid chromatography detection of terlipressin and its impurities, can solve the problems of waste of manpower and material resources, complete and effective separation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Flow rate: 0.4mL / min

[0059] Column temperature: 50°C

[0060] Column pressure: 6000psi

[0061] Injection volume: 5μL

[0062] Mobile phase A: 0.01M phosphoric acid-triethylamine aqueous solution (adjust pH=6.5 with ammonia water): acetonitrile=90:10;

[0063] Mobile phase B: 0.01M phosphoric acid-triethylamine aqueous solution (adjust pH=6.5 with ammonia water): acetonitrile=40:60;

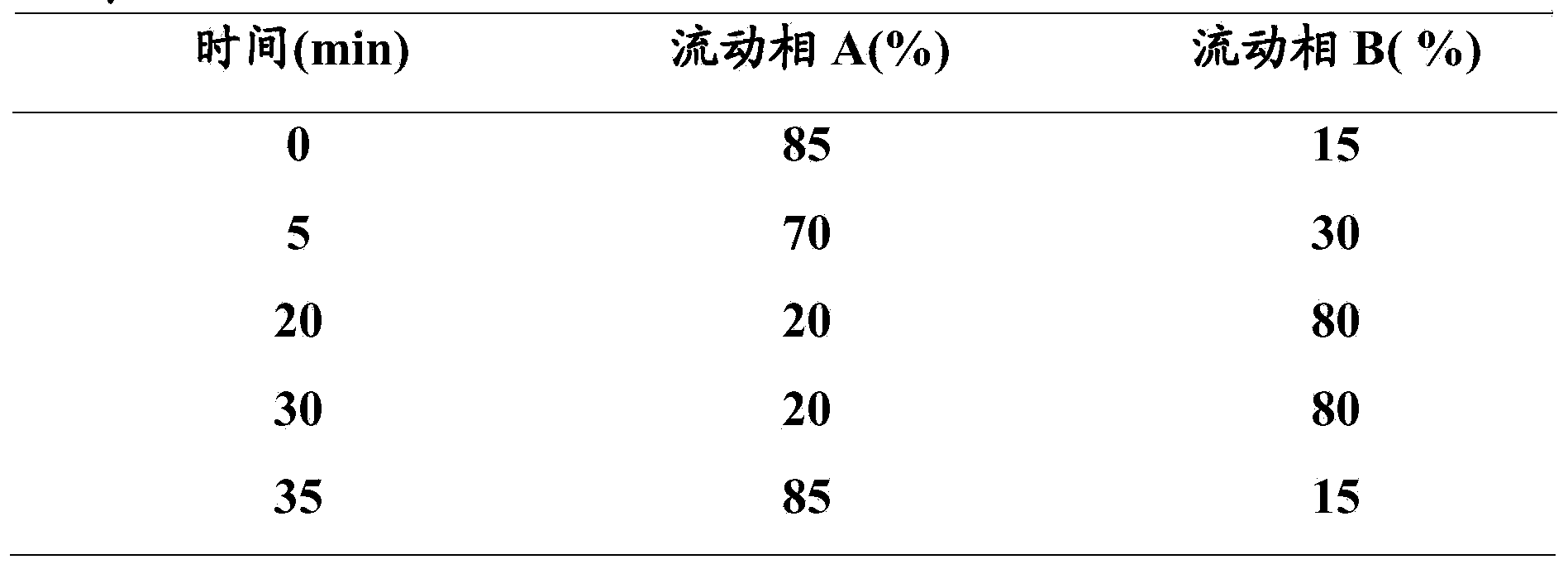

[0064] The gradient of mobile phase A and mobile phase B is shown in Table 4 below.

[0065] Table 4

[0066]

[0067] Weigh 100 mg of terlipressin, 10 mg of impurity A, 10 mg of impurity B, 10 mg of impurity C, 10 mg of impurity D, 10 mg of impurity E and 10 mg of impurity F, and dissolve them with the mobile phase A described in this example, in the same manner as in the comparative example Prepare the test sample solution and filter it with a Φ0.45 μm filter membrane. The concentration of terlipressin in the sample is 10 mg / mL, and the concentration of each impurity is 1 mg / mL...

Embodiment 2

[0072] Flow rate: 0.5mL / min

[0073] Column temperature: 50°C

[0074] Column pressure: 6000psi

[0075] Injection volume: 5μL

[0076] Mobile phase A: 0.01M phosphoric acid-triethylamine aqueous solution (phosphoric acid adjusts pH=3.0): acetonitrile=90:10;

[0077] Mobile phase B: 0.01M phosphoric acid-triethylamine aqueous solution (phosphoric acid to adjust pH=3.0): acetonitrile=40:60,

[0078] The gradient of mobile phase A and mobile phase B is the same as in Table 2.

[0079] Weigh 100 mg of terlipressin, 10 mg of impurity A, 10 mg of impurity B, 10 mg of impurity C, 10 mg of impurity D, 10 mg of impurity E and 10 mg of impurity F, and dissolve them with the mobile phase A described in this example, in the same manner as in the comparative example The test sample was prepared and filtered with a Φ0.45 μm filter membrane. The concentration of terlipressin in the sample was 10 mg / mL, and the concentration of each impurity was 1 mg / mL. Set the flow rate to 0.5mL / min, ...

Embodiment 3

[0084] Flow rate: 0.6mL / min

[0085] Column temperature: 50°C

[0086] Column pressure: 6000psi

[0087] Injection volume: 5μL

[0088] Mobile phase A: 0.01M phosphoric acid-triethylamine aqueous solution (phosphoric acid adjusts pH=3.2): acetonitrile=90:10;

[0089] Mobile phase B: 0.01M phosphoric acid-triethylamine aqueous solution (phosphoric acid to adjust pH=3.2): acetonitrile=40:60,

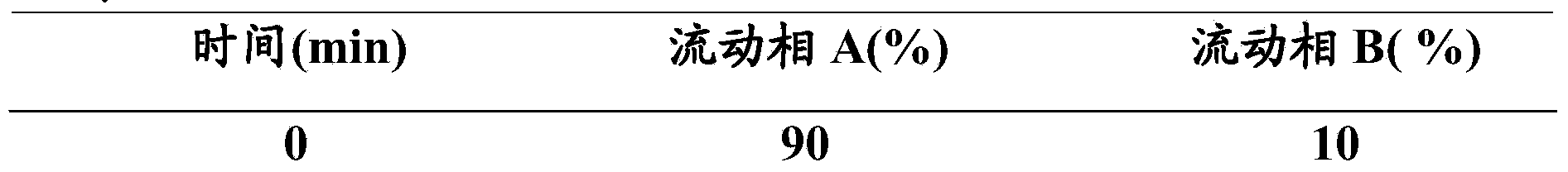

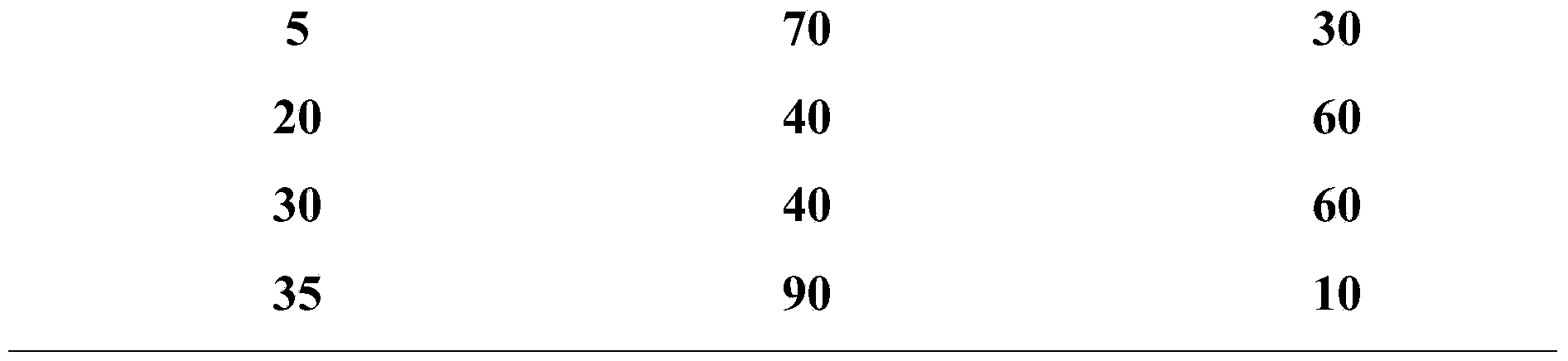

[0090] The gradient of mobile phase A and mobile phase B is shown in Table 7 below.

[0091] Table 7

[0092]

[0093] Weigh 100 mg of terlipressin, 10 mg of impurity A, 10 mg of impurity B, 10 mg of impurity C, 10 mg of impurity D, 10 mg of impurity E and 10 mg of impurity F, and dissolve them with the mobile phase A described in this example, in the same manner as in the comparative example The test sample was prepared and filtered with a Φ0.45 μm filter membrane. The concentration of terlipressin in the sample was 10 mg / mL, and the concentration of each impurity was 1 mg / mL. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com