Flexible organic flat panel ultraviolet light source and preparation method thereof

An ultraviolet light source and organic technology, applied in the field of ultraviolet light source, can solve the problem of low ultraviolet transmittance, achieve the effects of reducing process precision requirements, increasing yield rate, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

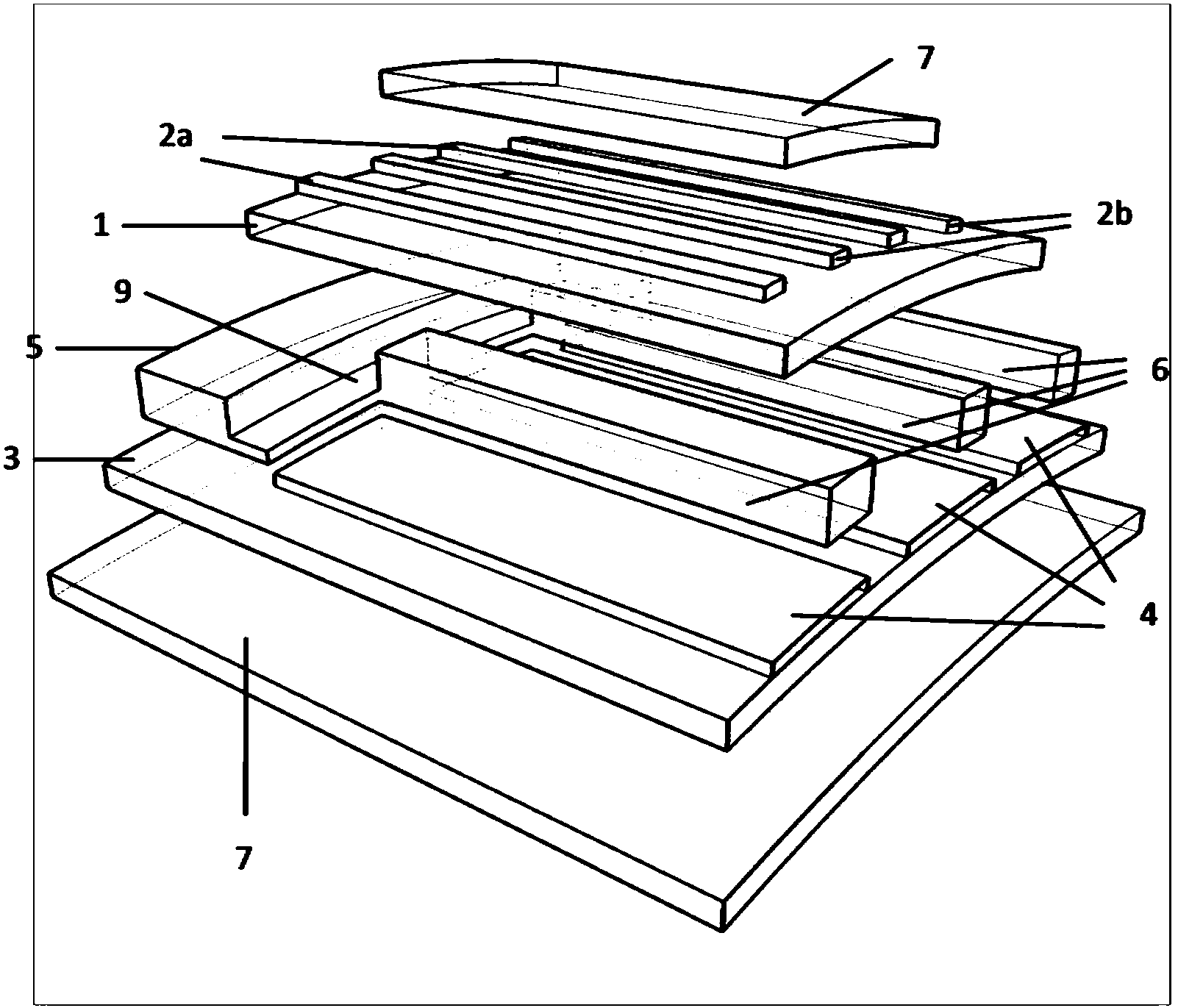

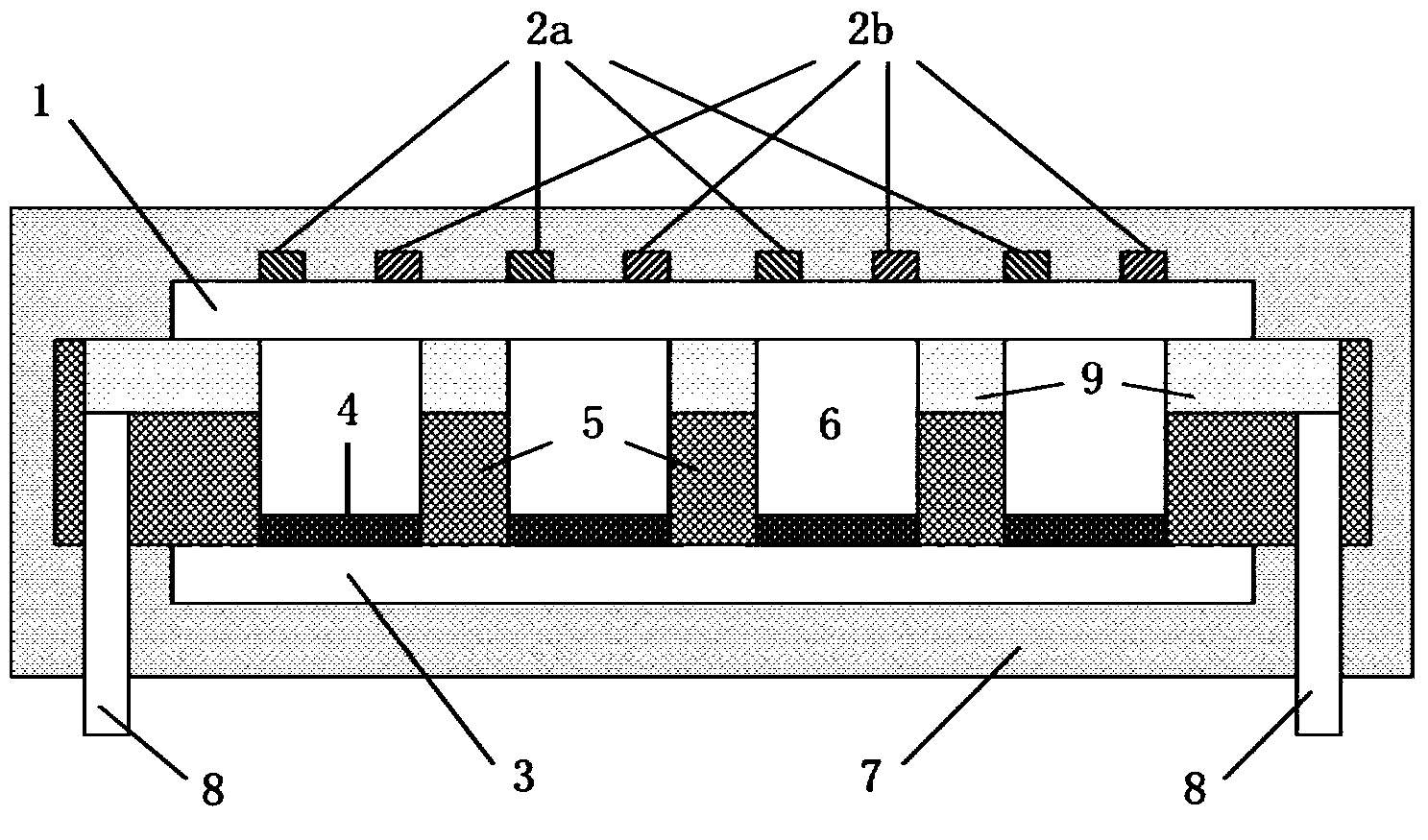

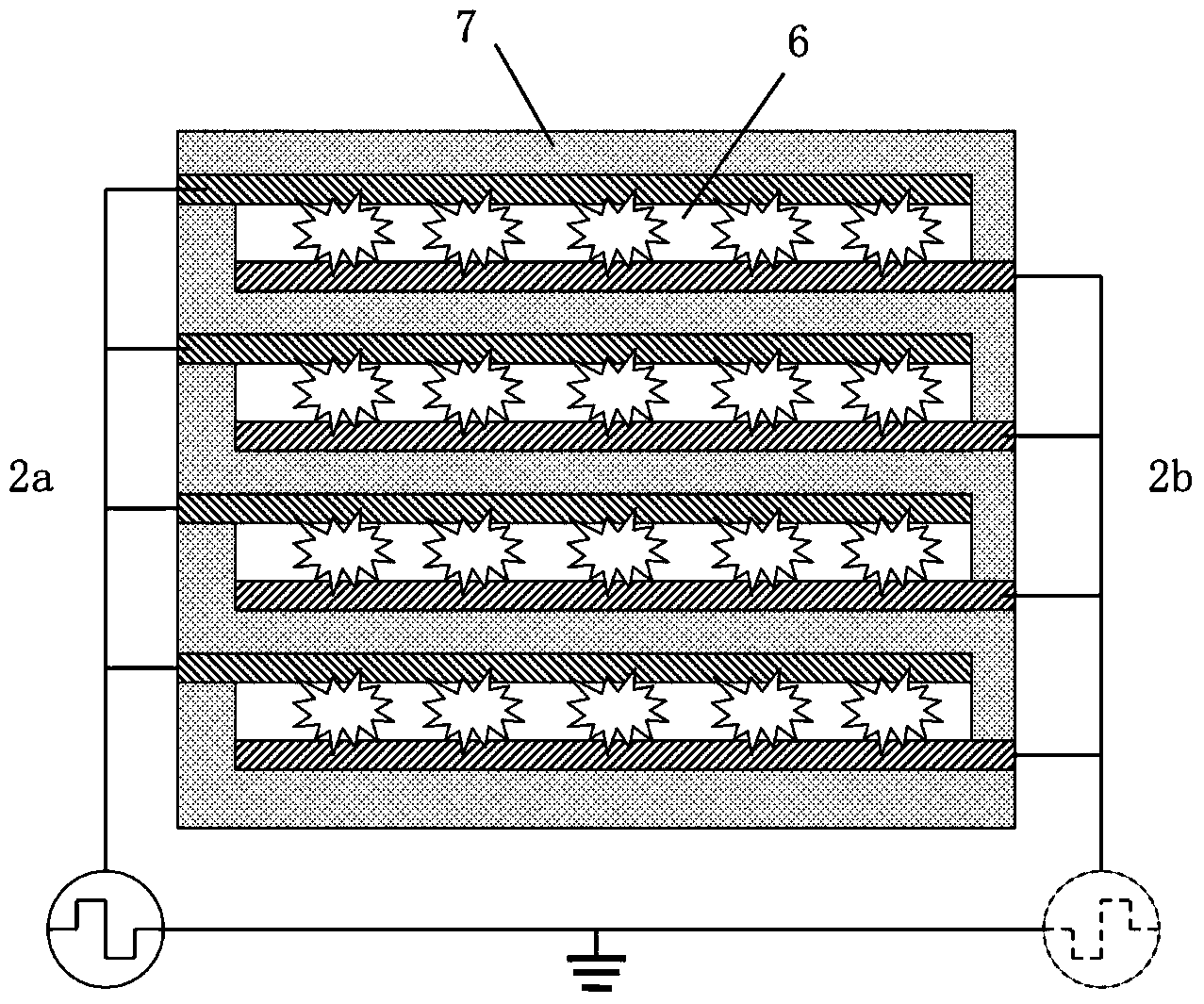

[0022] Such as figure 1 , 2 shown. Prepare electrode group 2a and electrode group 2b on front substrate glass 1, prepare phosphor layer 4 on rear substrate glass 3, add organic cavity layer 5 between described front substrate glass 1 and rear substrate glass 3, make organic The cavity 6 in the cavity layer 5 corresponds to the electrode group 2a and the electrode group 2b, and finally the front substrate glass 1 and the rear substrate glass 3 are covered with an organic polymer 7, and an exhaust pipe 8 is connected.

[0023] Microchannels 9 are prepared in the organic cavity layer 5, communicating with the cavity 6 and the exhaust pipe 8, so that all discharge spaces can be inflated and exhausted effectively. One or two exhaust pipes 8 can be used at the same time, and finally filled with Ar as the working gas, the pressure is 400-760torr, and then the exhaust pipe 8 is sealed.

[0024] It works as follows. It is divided into applying reverse positive and negative AC pulse...

Embodiment 2

[0026] The working gas in Example 1 is replaced by Xe (>20%) and Ne mixed gas, the Xe and Ne mixed gas discharges to emit vacuum ultraviolet light mainly at 147nm and 172nm, and then excites the fluorescent layer 4 to emit ultraviolet light.

Embodiment 3

[0028] The working gas in embodiment 1 is replaced by a pure Xe body, since the gas pressure is at 400-760 Torr, the three-body collision between the ground state Xe atom and the excited state Xe atom (such as ) increases, so that the gas discharge emits mainly 172nm vacuum ultraviolet light, and then excites the fluorescent layer 4 to emit ultraviolet light, which is emitted through the front substrate glass 1 and the organic polymer 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com