Lithium-sulfur flow battery and positive electrode electrolyte thereof, as well as preparation method of positive electrode electrolyte

A lithium-sulfur flow battery and cathode electrolyte technology, which is applied in battery electrodes, fuel cells, secondary batteries, etc., can solve the problems of increased electrolyte concentration and viscosity on the positive electrode side, and prevent capacity fading and prevent capacity fading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Difference item in each embodiment of table 1

[0056]

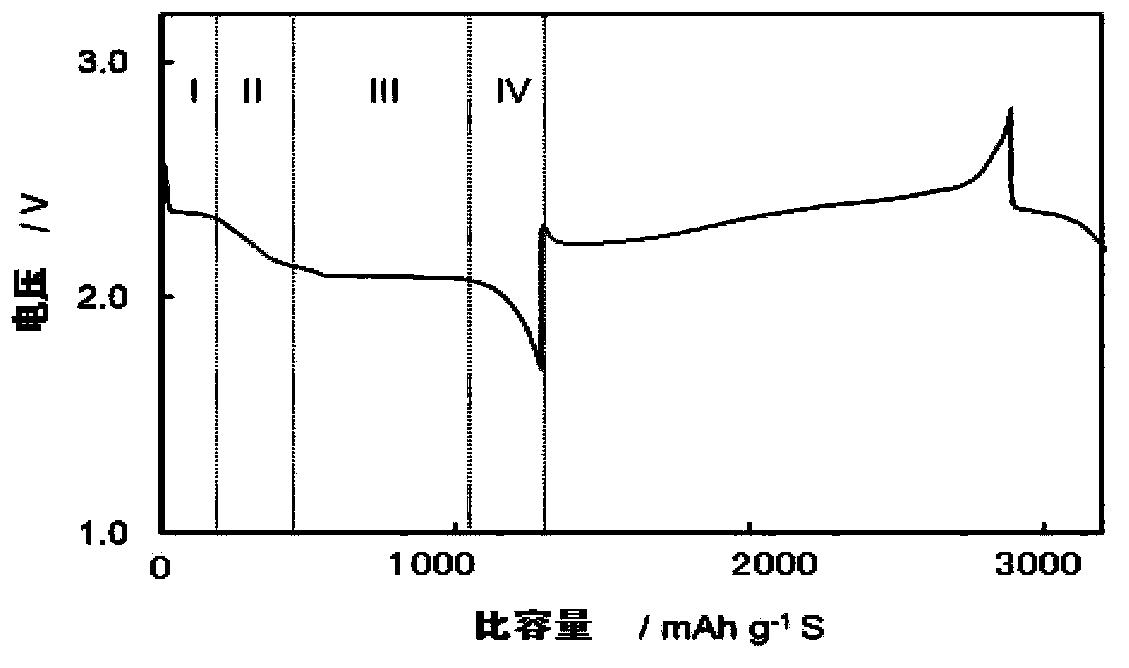

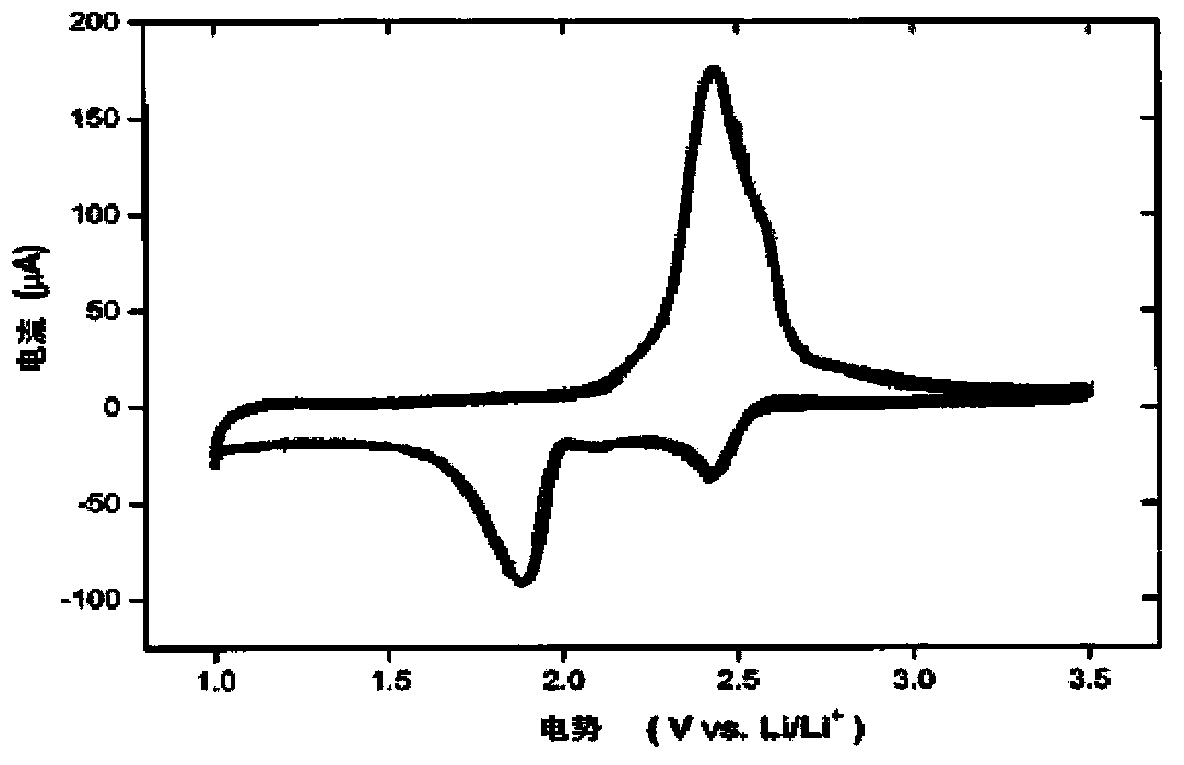

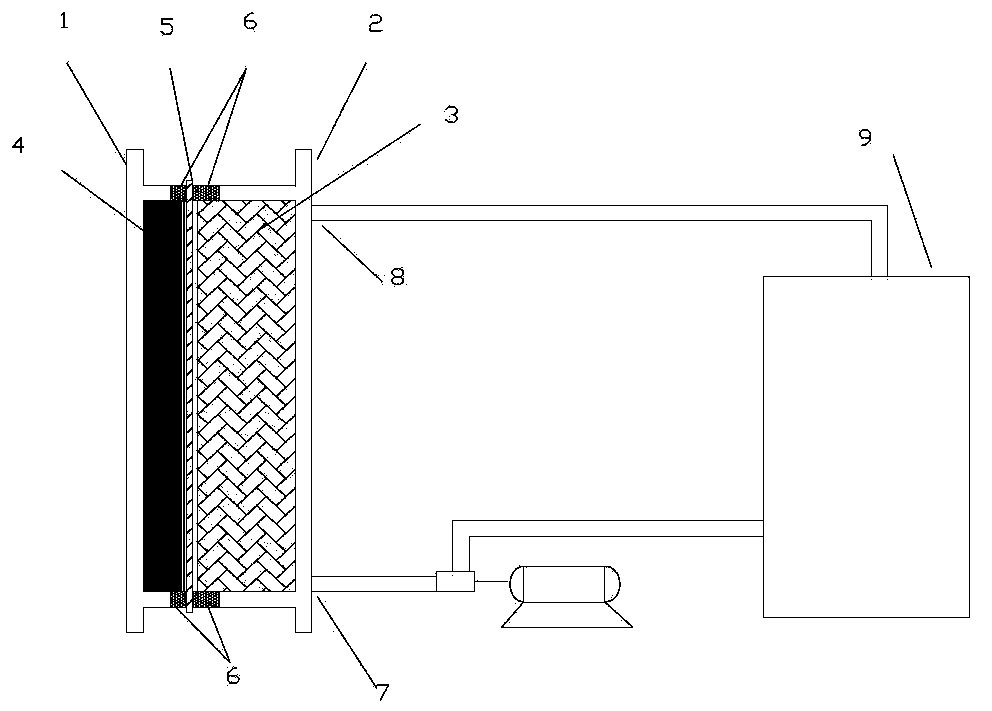

[0057] In the embodiment of the present invention, according to the sequence described in the description, the first step is to prepare the electrolyte, wherein the solvent is ethylene glycol dimethyl ether (DME, 99%, Aldrich) and 1.3-dioxolane (DOL, 99.8%, Aldrich) were mixed according to the volume ratio of 1:1, and stirred for 36 hours to form the electrolyte solute. Lithium trifluoromethanesulfonate (LiSO 3 CF 3 , 99.95%, Aldrich) as the solute, dissolved in the prepared mixed solvent, the concentrations of the electrolytes in different examples are shown in Table 1. In the second step, use the negative electrode electrolyte prepared in step 1, introduce lithium and sulfur according to the mass ratio of 1:4, and stir in the mixed solvent for 48 hours until the solids are completely reacted and dissolved, forming dark brown Li 2 S 8 solution, the concentration of the solution is shown in Table 1. Weigh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com