Full-automatic freeze drying pharmaceutical equipment

A kind of pharmaceutical equipment and fully automatic technology, applied in the direction of making medicines into special physical or taking form devices, etc., can solve the problems of insufficient intelligent control, low production efficiency, microbial contamination, etc., to avoid microbial contamination and improve production. Efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

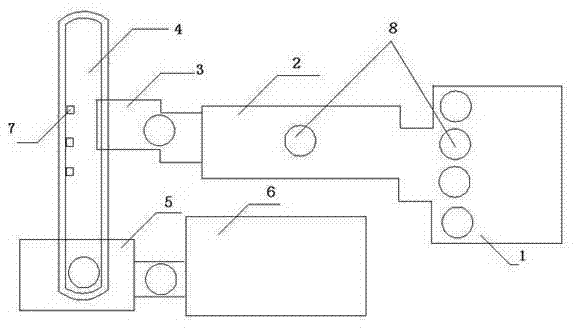

[0019] Such as figure 1 Shown: fully automatic freeze-drying pharmaceutical equipment, including a bottle washing machine 1 for cleaning medicine bottles, a tunnel oven 2 connected to the bottle washing machine 1, and a tunnel oven 2 for drying, sterilization and heat source removal, drying and The filling machine 3 connected to the tunnel oven 2, the filling machine 3 is used to fill the liquid medicine and half-stopper the medicine bottle, the conveyor belt 4 connected to the filling machine 3, the alignment device 5 connected to the conveyor belt 4, the alignment The device 5 is used for arranging the medicine bottles and pushing the medicine bottles into the freeze dryer 6. The freeze dryer 6 is also connected with a freeze-drying box, which can be connected and separated from the freeze-drying machine 6.

Embodiment 2

[0021] Such as figure 1 Shown: fully automatic freeze-drying pharmaceutical equipment, including a bottle washing machine 1 for cleaning medicine bottles, a tunnel oven 2 connected to the bottle washing machine 1, and a tunnel oven 2 for drying, sterilization and heat source removal, drying and The filling machine 3 connected to the tunnel oven 2, the filling machine 3 is used to fill the liquid medicine and half-stopper the medicine bottle, the conveyor belt 4 connected to the filling machine 3, the alignment device 5 connected to the conveyor belt 4, the alignment The device 5 is used for arranging the medicine bottles and pushing the medicine bottles into the freeze dryer 6 . An infrared sensor 7 is also provided on the conveyor belt 4, which is used to collect and detect information on the number of medicine bottles, etc., and through cooperation with the automatic controller, it can control the start and stop of the conveyor belt and control the freeze-drying machine. 6...

Embodiment 3

[0023] Such as figure 1 Shown: fully automatic freeze-drying pharmaceutical equipment, including a bottle washing machine 1 for cleaning medicine bottles, a tunnel oven 2 connected to the bottle washing machine 1, and a tunnel oven 2 for drying, sterilization and heat source removal, drying and The filling machine 3 connected to the tunnel oven 2, the filling machine 3 is used to fill the liquid medicine and half-stopper the medicine bottle, the conveyor belt 4 connected to the filling machine 3, the alignment device 5 connected to the conveyor belt 4, the alignment The device 5 is used for arranging the medicine bottles and pushing the medicine bottles into the freeze dryer 6. The freeze dryer 6 is also connected with a freeze-drying box, which can be connected and separated from the freeze-drying machine 6. The bottle washing machine, the tunnel oven connected to the bottle washing machine, the filling machine connected to the tunnel oven, the conveyor belt connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com