Technology for extruding specially-shaped aluminum barrel with square head

A special-shaped and process technology, applied in the direction of metal extrusion dies, etc., can solve the problems of affecting product consistency, high cost of consumables, and high cost, and achieve the effects of stable product quality, convenient operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

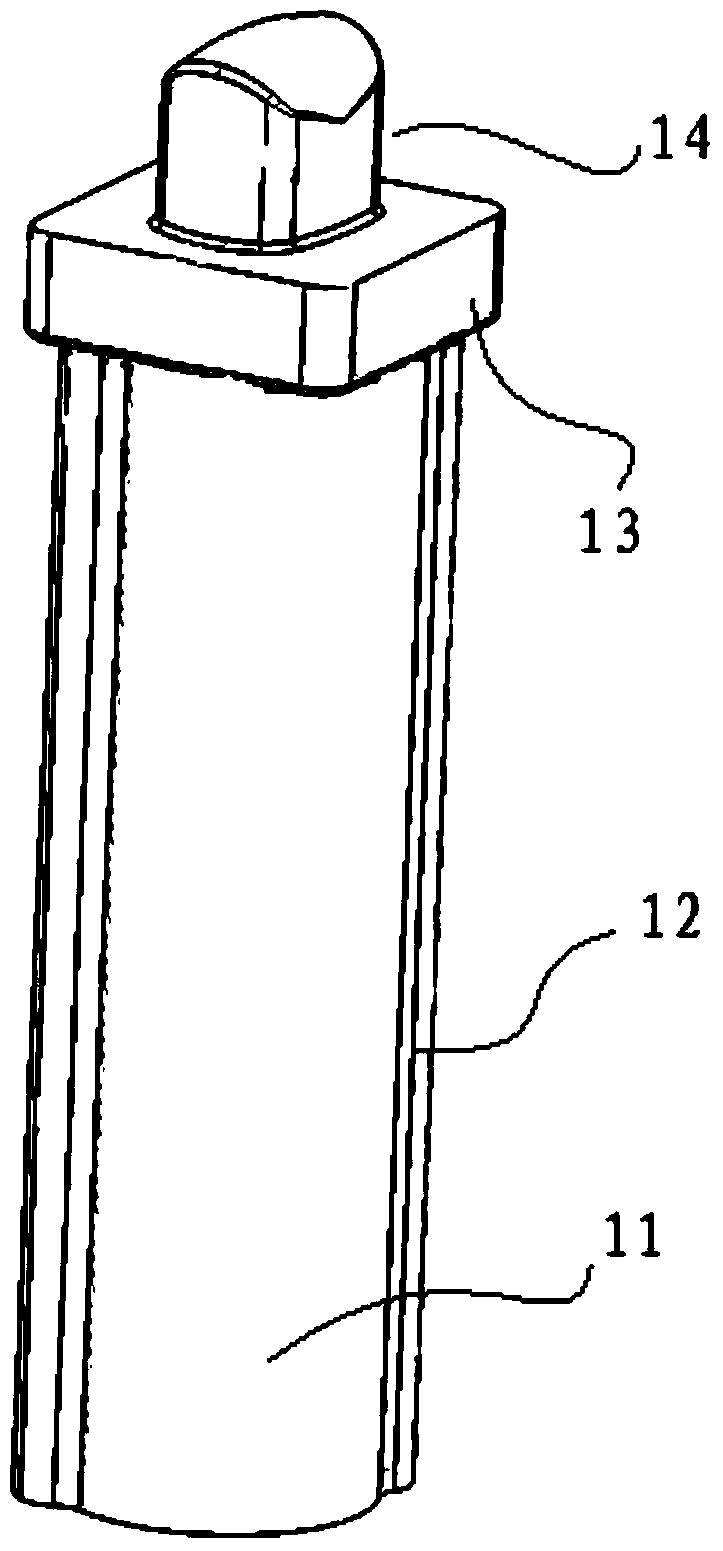

[0026] see figure 1 , the structure of the special-shaped cylinder with a square head is a cylinder body 11, a square head 13, and an oval protrusion 14 from bottom to top. Two convex ribs 12 are symmetrically arranged on the outer surface of the cylinder, and the symmetrical axis of the two convex ribs 12 overlaps with the center line of the square head 13, and the long axis and the short axis of the oval protrusion 14 are respectively aligned with the square head 13. The two centerlines of .

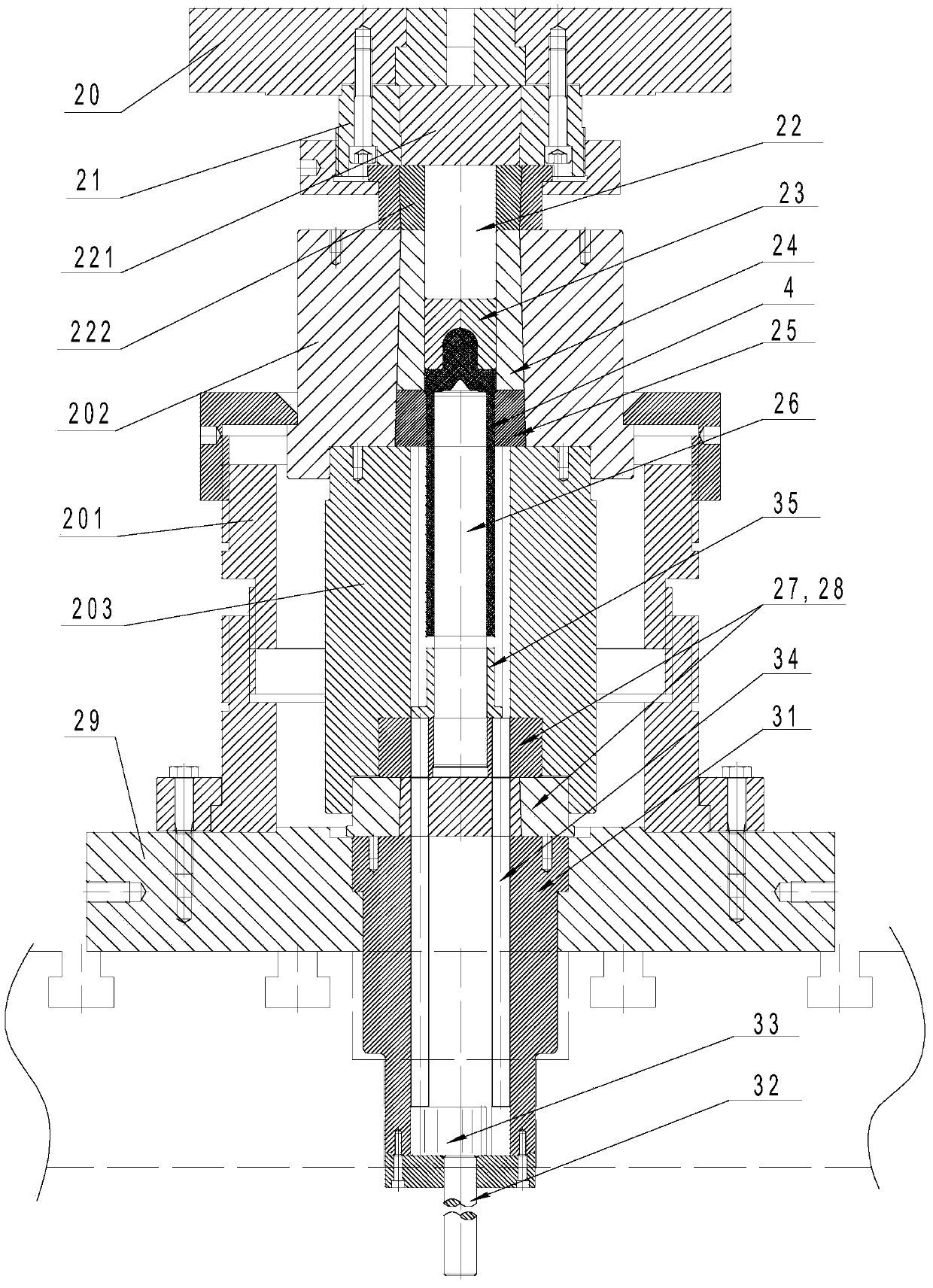

[0027] The extrusion process of the aluminum square-head special-shaped cylinder of the present invention can form the blank into an extrusion of the square-head special-shaped cylinder through a single extrusion process, and the extrusion can be formed into a cylinder billet, a square-end billet and an oval convex The billet is blanked, and the center line of the square billet is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com