Continuous oxygen generator with integrated molecular sieve adsorption tower

A molecular sieve and adsorption tower technology, applied in the field of continuous oxygen generators, can solve problems such as neglect, and achieve the effects of prolonging life, saving solenoid valves and solenoid valve switching control systems, and avoiding excessive pressure changes and temperature changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the drawings.

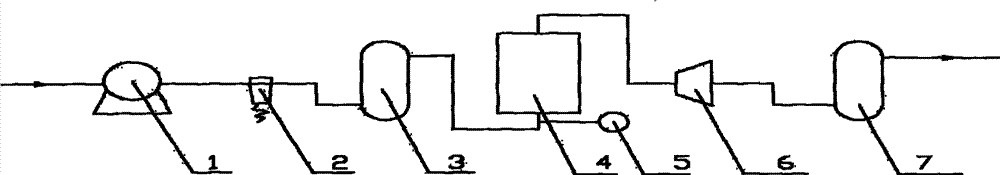

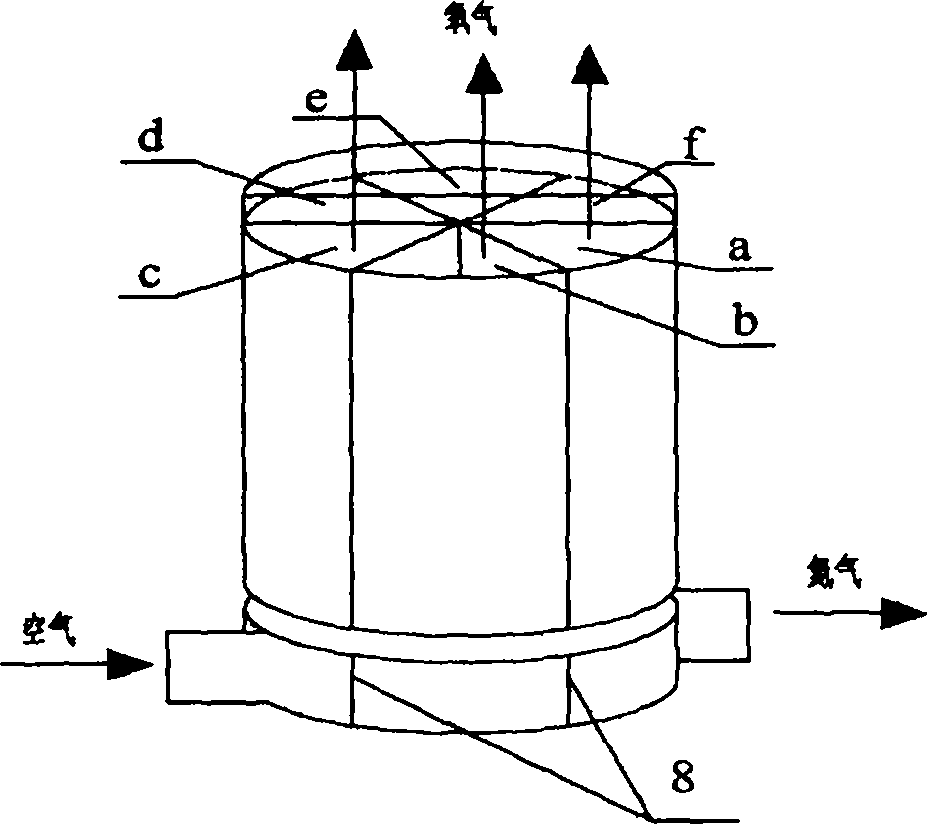

[0027] As attached figure 1 As shown, a continuous oxygen generator equipped with an integrated molecular sieve adsorption tower consists of an air compressor (1), a pretreatment device (2), an air buffer tank (3), an integrated molecular sieve adsorption tower (4), and a step The inlet motor (5), the supercharger (6), and the oxygen storage tank (7) are composed. The air compressor (1) provides compressed air for the oxygen system. The pretreatment device (2) consists of a multilayer filter membrane and an oil removal membrane. It is composed of flakes and desiccant, which can remove fine particles, oil and moisture. The air buffer tank (3) can ensure the stability of the inlet airflow and air pressure. The integrated molecular sieve adsorption tower (4) is the core oxygen production component. The adsorption capacity and adsorption rate are different under different pressures. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com