Flatting agent for polyester-hydroxyalkylamide type powder coating and preparation method thereof

A hydroxyalkyl amide powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of reducing coating leveling, impact resistance, mechanical properties and storage stability, and achieve good The effect of matting effect, large market space and implementation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

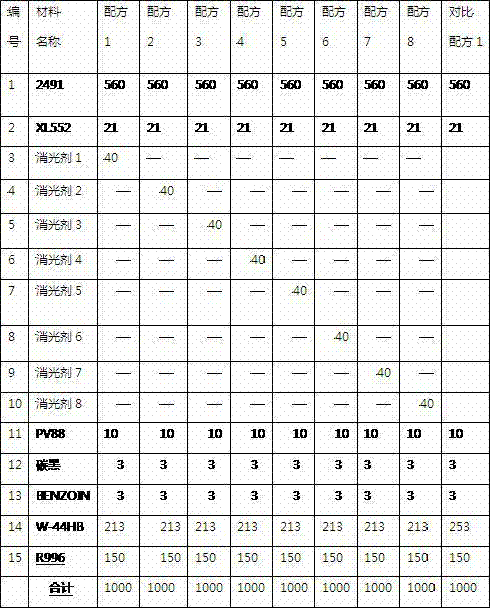

Image

Examples

Embodiment 1

[0018] 100g of glycidyl methacrylate, 30g of tert-butyl methacrylate, 20g of styrene, 8g of methyl methacrylate, 42g of isobutyl methacrylate, 2g of azobisisovaleronitrile Add the mixed solution dropwise. 200g of tert-butanol was added into a 1000ml three-neck flask and heated and stirred. When the temperature reaches 80°C-85°C, start to add the mixed solution dropwise, finish the dropwise addition after 90 minutes, and keep the temperature at 80°C-85°C for 2 hours. Evaporate the solvent under reduced pressure, the temperature does not exceed 160°C, discharge while hot, cool, and coarsely pulverize to obtain acrylic synthetic resin A with a glass transition temperature of 55°C and a number average molecular weight of 4500.

[0019] Mix and pulverize 50g of synthetic acrylic resin A, 110g of tetradecanoic acid, 30g of wax substance Deuteron wax MPO?, and 10g of zinc stearate in a weight ratio of 6:10:3:1 to make a matte Agent 1.

[0020]

Embodiment 2

[0021] Example 2 70g of synthetic acrylic resin A, 50g of dodecanedioic acid, 40g of sebacic acid, 30g of wax substance Deuteron wax MPO?, 10g of aluminum stearate, according to the ratio of 7:5::4: Mix and pulverize at a weight ratio of 3:1 to make matting agent 2.

[0022]

Embodiment 3

[0024] 120g of glycidyl methacrylate, 30g of n-butyl methacrylate, 10g of styrene, 8g of methyl methacrylate, 32g of isobutyl methacrylate, 2g of azobisisovaleronitrile Add the mixed solution dropwise. Dissolve 1 g of benzoyl peroxide in 40 g of tert-butanol to prepare an additional initiator solution. 200g of tert-butanol was added into a 1000ml three-neck flask and heated and stirred. When the temperature reaches 80°C-85°C, start to add the mixed solution dropwise, finish the dropwise addition after 90 minutes, and keep the temperature at 80°C-85°C for 1 hour. Start to add the initiator solution, and keep warm for 1h after the addition. The solvent was distilled off under reduced pressure, and the temperature did not exceed 160°C. Discharge while hot, cool, and coarsely pulverize to obtain an acrylic synthetic resin B with a glass transition temperature of 50°C and a number average molecular weight of 6,500.

[0025] 60g of synthetic acrylic resin B, 80g of undecyl diaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com