Multifunctional constant-volume bomb for testing spraying, burning and soot generation characteristics

A technology of constant volume bombs and soot, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve problems such as heating, force asymmetry, explosion, and deformation of bombs, and achieve flexible and convenient layout. Improve experimental efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereto.

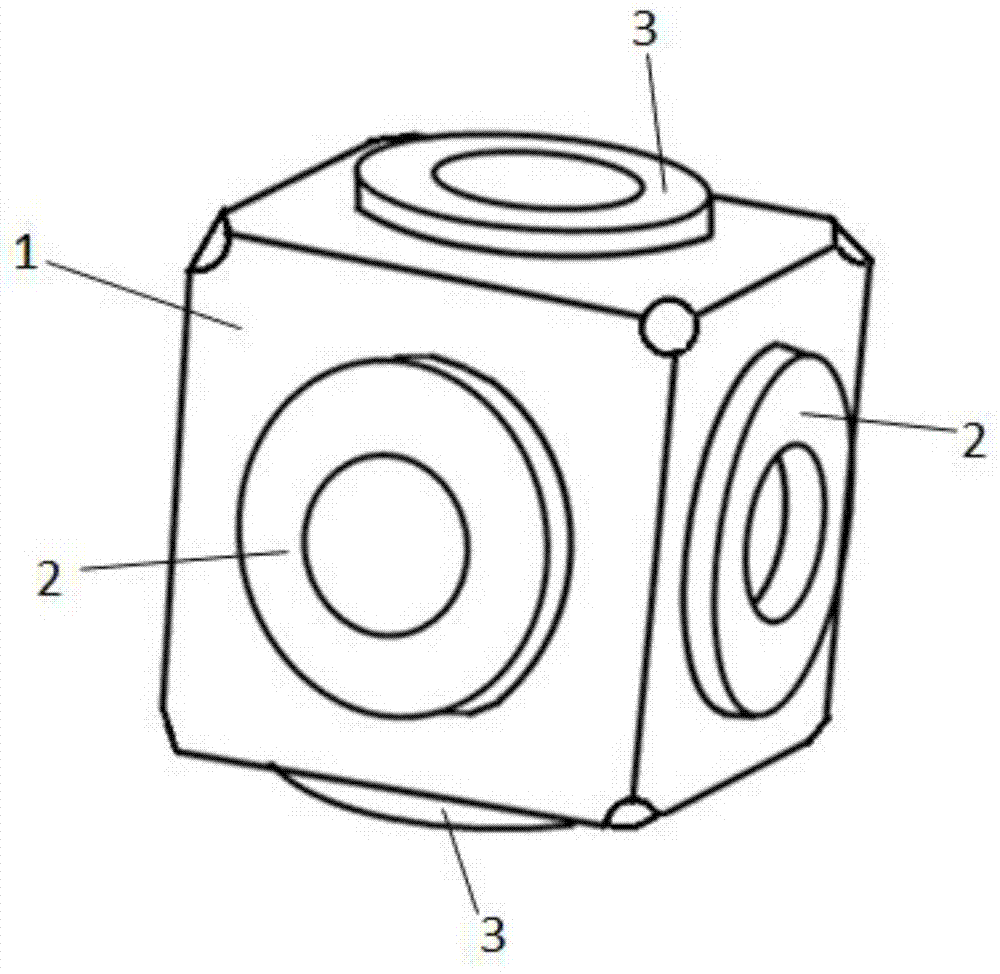

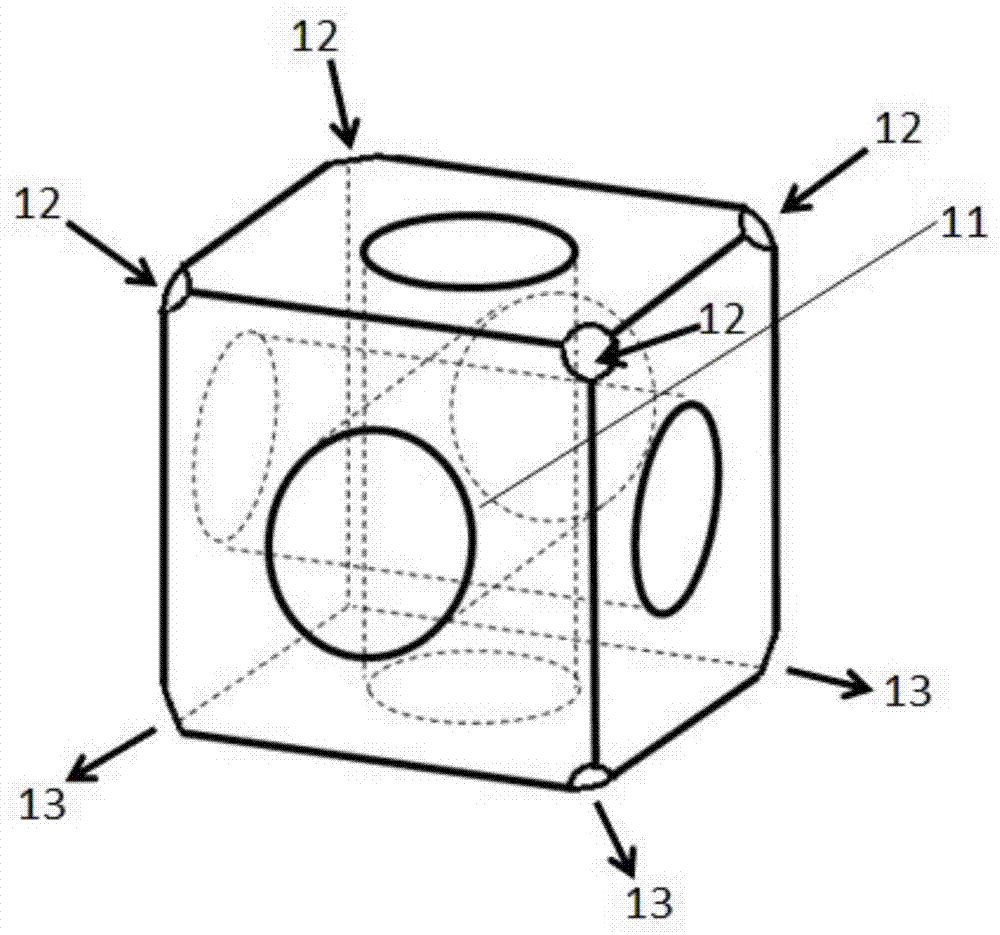

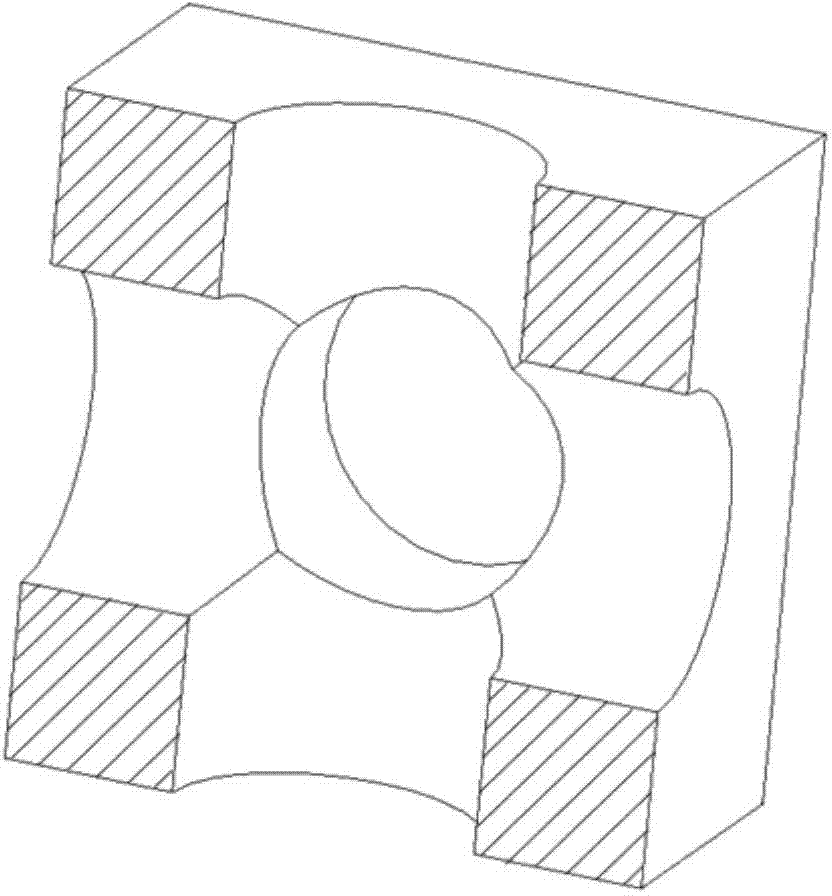

[0035] A kind of constant volume bomb used for spraying, combustion and soot generation characteristics test provided by the present invention, the assembly schematic diagram is as follows figure 1 As shown, it mainly includes: a bomb containing body 1, an optical window 2 (there are four in this embodiment, arranged in the circumferential direction, and two are shown in the figure), an end cover 3 and an air inlet heating system (the air inlet heating system is set on On the outside of each air inlet of the main body, the constant volume bomb is used to heat the air intake during the high temperature test, which is not shown in the figure and will be described below). The four optical windows and the two end caps are respectively connected to the six surfaces of the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com