Color filter substrate and fabrication method and display device thereof

A technology of color film substrate and manufacturing method, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, photoplate making process of patterned surface, etc., and can solve problems such as large spacer thickness, low aperture ratio, and transparent electrode breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

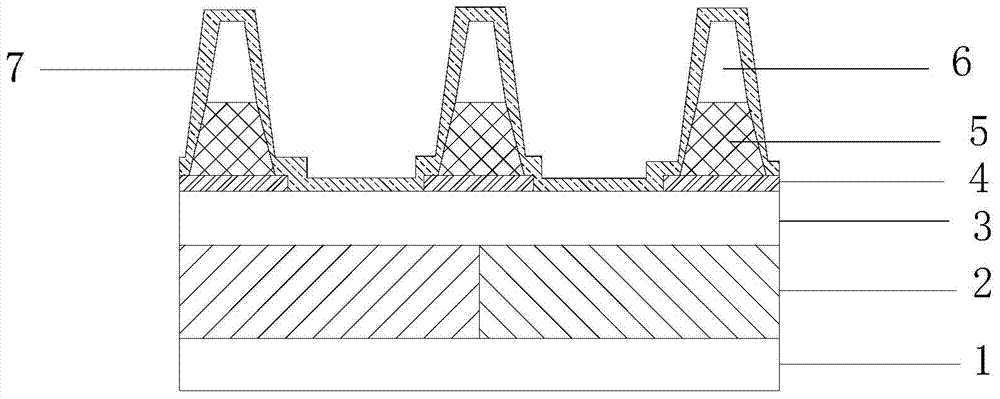

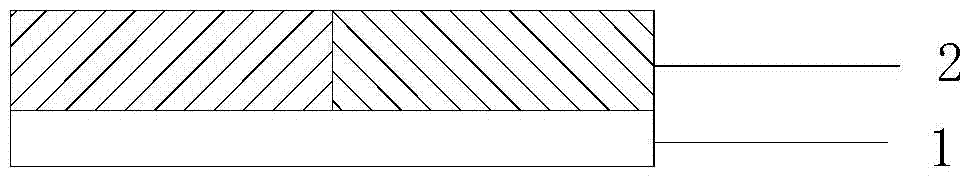

[0040] Such as figure 1 As shown, the present invention provides a color filter substrate, which includes a transparent substrate 1, the transparent substrate 1 can be made of glass and other materials; the transparent substrate 1 is provided with a photoresist layer 2, and the photoresist layer 2 It includes at least a plurality of red photoresist units, a plurality of green photoresist unit layers and a plurality of blue photoresist units; of course, in order to enrich the display color and improve brightness, the color photoresist layer 2 may also include other color photoresist units.

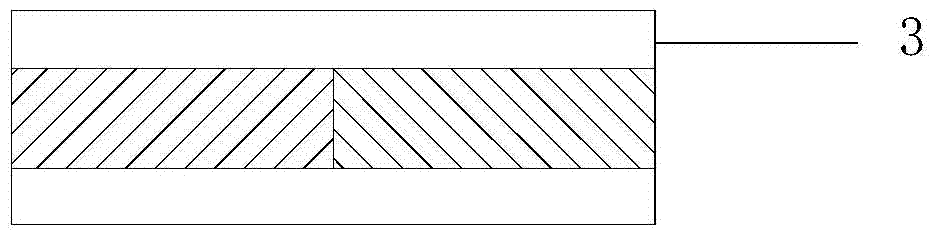

[0041] The photoresist layer 2 is provided with a protective layer 3. The protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com