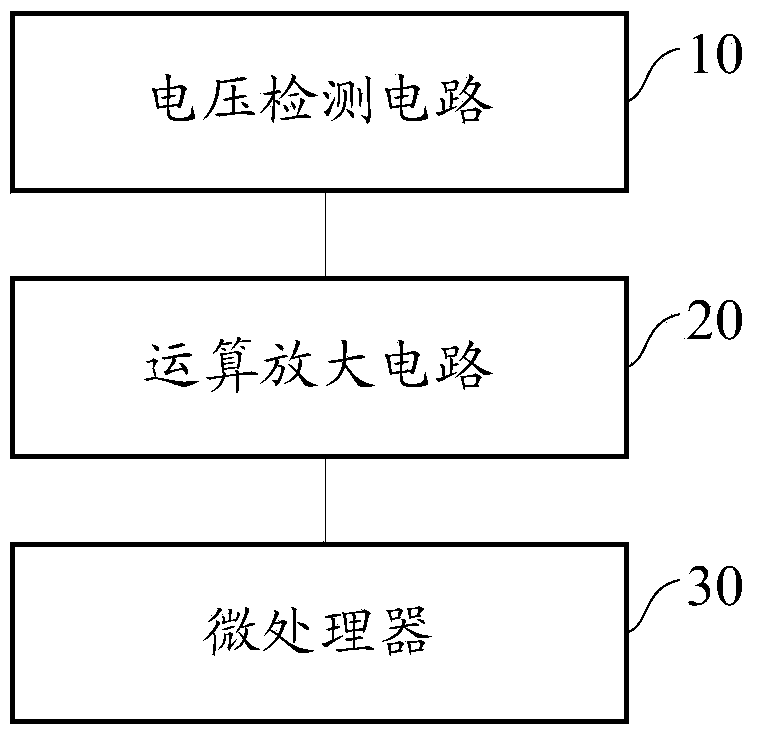

Current detection device and method

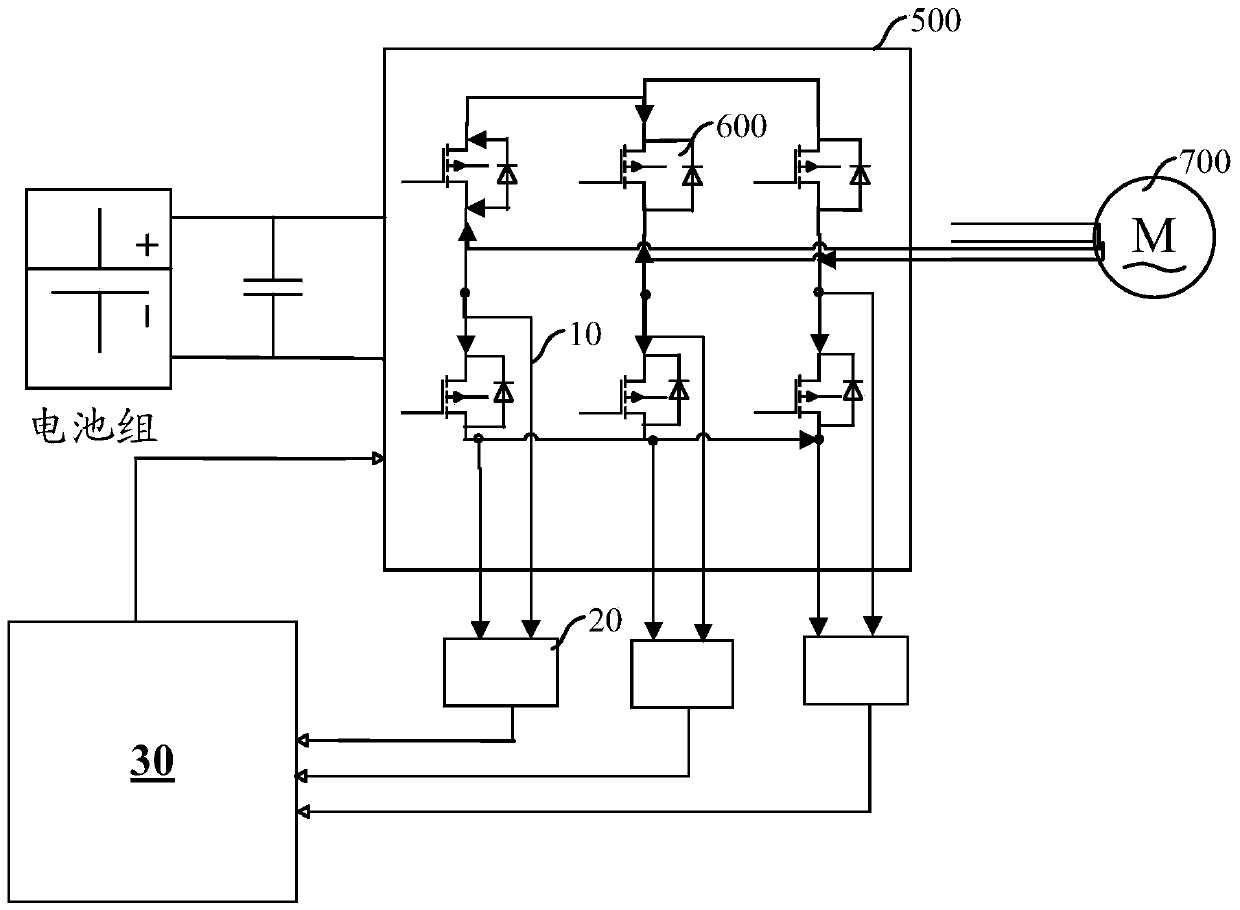

A current detection device and current technology, applied in the direction of controlling electromechanical transmission devices, electrical components, controlling generators, etc., can solve the problems of expensive Hall sensors, large size and high cost of Hall sensors, and achieve easy printed board layout. Realize, save hardware cost, and have the effect of good cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention .

[0067] The main problem to be solved by the invention is to provide a novel current detection device and method for the problem that the current general frequency converter current sampling method is difficult to apply to the low-voltage electric vehicle driver.

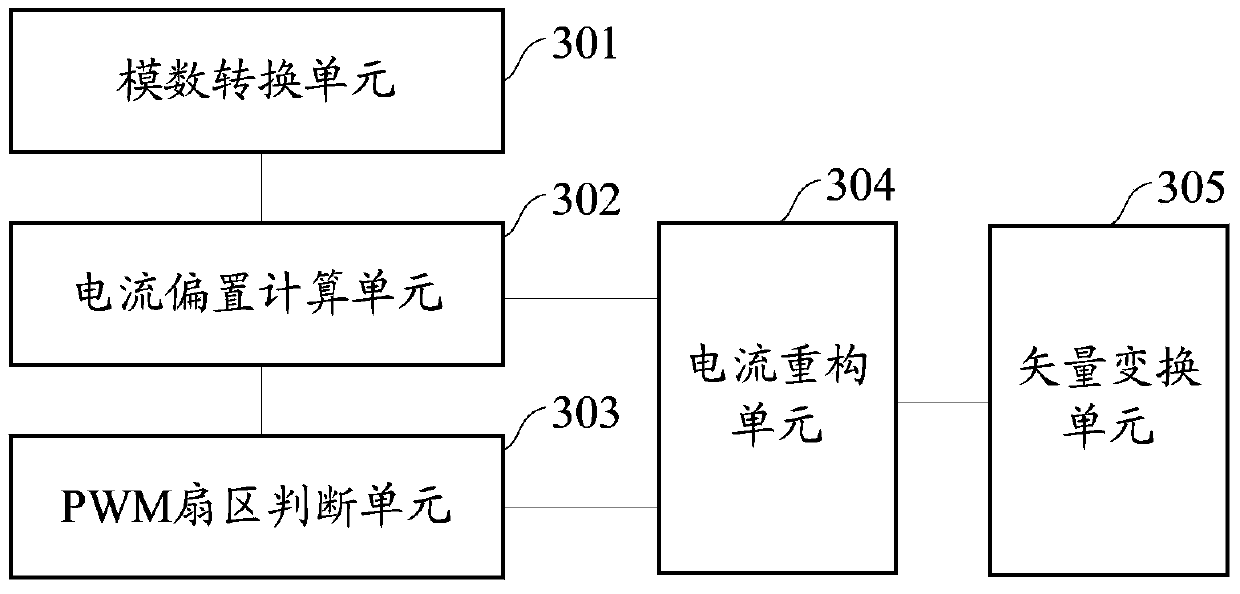

[0068] The core idea of the present invention to solve the above-mentioned technical problems is to use the conduction voltage drop of the MOSFET to perform current sampling and calculation to obtain the current value of the bridge arm, and then perform current reconstruction according to the sector of the space voltage vector PWM (SVPWM) to obtain the phase of the current. current. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com