High thermal conductivity metal substrate and manufacturing method thereof

A technology of metal substrate and manufacturing method, which is applied in the directions of printed circuit manufacturing, printed circuit components, electrical components, etc. features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

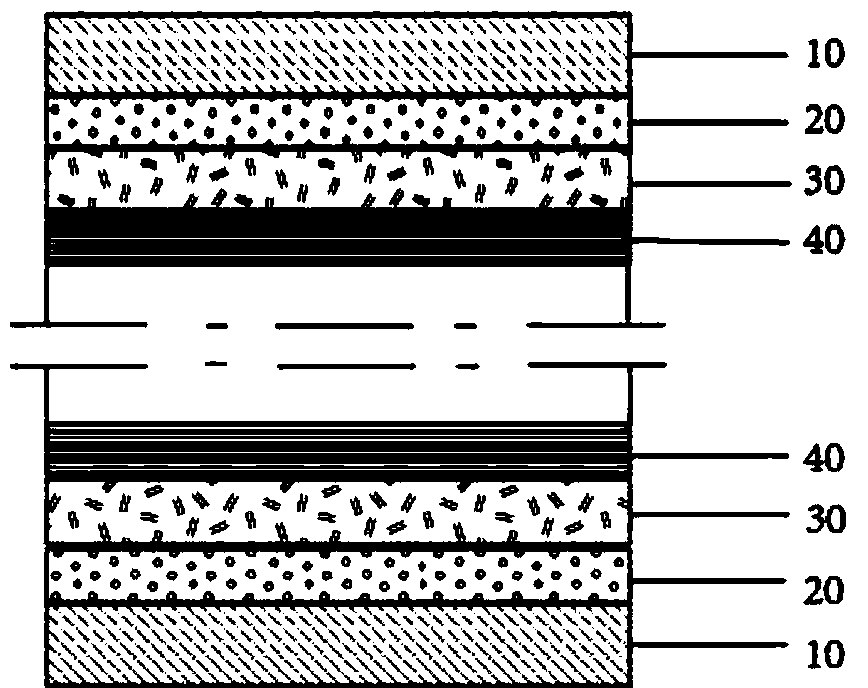

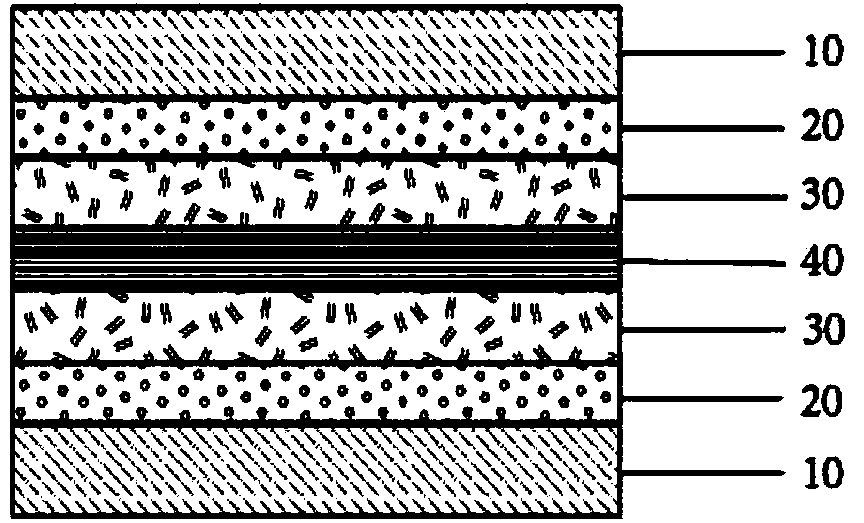

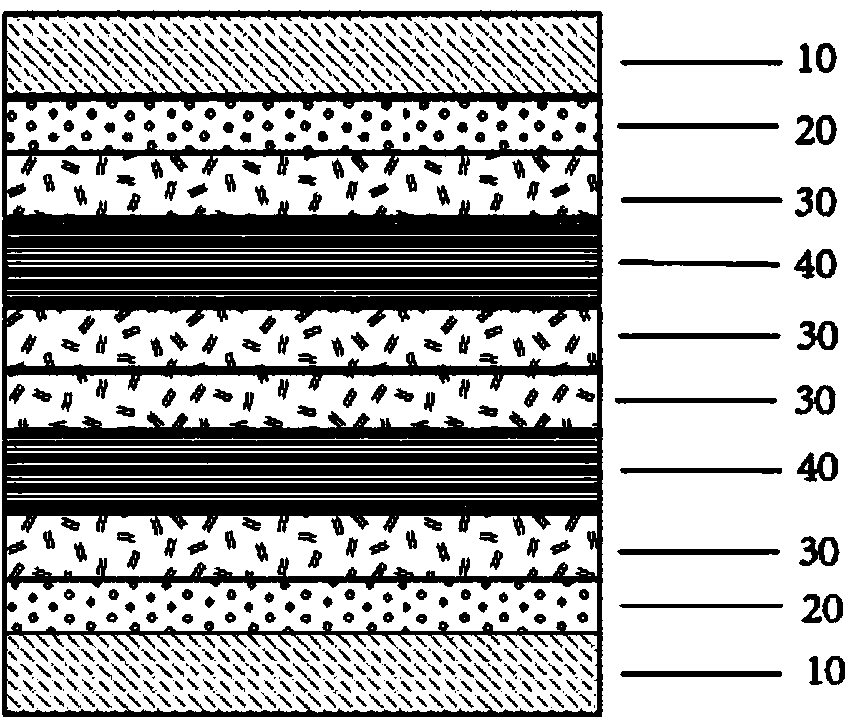

[0074] On each side of a porous LCP film with a thickness of 50μm and a porosity of 50%, a 15μm thick cyanate ester thermal conductive glue with a thermal conductivity of 4.0W / mK is coated on each side. After heating and baking, the LCP is reinforced The prepreg of the material: Coat a layer of 40μm thick epoxy thermal conductive glue with a thermal conductivity of 2.0W / mK on the roughened surface of the 35μm copper foil. After heating and baking, the glued copper foil is obtained, according to the glued copper foil / LCP prepreg / coated copper foil laminated structure for lamination, the specific structure is as figure 2 , The above-mentioned prepared laminated blank material is sandwiched between two mirror stainless steel plates, and then put into the laminator, at a temperature of 200℃, a pressure of 4MPa, and a pressing time of 90 minutes to obtain a high thermal conductivity metal substrate .

Embodiment 2

[0076] Coat each side of a porous LCP film with a thickness of 50μm and a porosity of 70% with a thickness of 15μm with the above-mentioned cyanate ester thermal conductive glue with a thermal conductivity of 4.0W / mK. After heating and baking, the LCP is reinforced The prepreg of the material: Coat a layer of 40μm thick epoxy thermal conductive glue with a thermal conductivity of 2.0W / mK on the roughened surface of the 35μm copper foil. After heating and baking, the glued copper foil is obtained, according to the glued copper foil / LCP prepreg / coated copper foil laminated structure for lamination, the specific structure is as figure 2 , The above-mentioned prepared laminated blank material is sandwiched between two mirror stainless steel plates, and then put into the laminator, at a temperature of 200℃, a pressure of 4MPa, and a pressing time of 90 minutes to obtain a high thermal conductivity metal substrate .

Embodiment 3

[0078] Coat each side of the porous LCP film with a thickness of 50μm and porosity of 90% with a thickness of 15μm with the above-mentioned cyanate ester thermal conductive glue with a thermal conductivity of 4.0W / mK. After heating and baking, the LCP is reinforced The prepreg of the material: Coat a layer of 40μm thick epoxy thermal conductive glue with a thermal conductivity of 2.0W / mK on the roughened surface of the 35μm copper foil. After heating and baking, the glued copper foil is obtained, according to the glued copper foil / LCP prepreg / coated copper foil laminated structure for lamination, the specific structure is as figure 2 , The above-mentioned prepared laminated blank material is sandwiched between two mirror stainless steel plates, and then put into the laminator, at a temperature of 200℃, a pressure of 4MPa, and a pressing time of 90 minutes to obtain a high thermal conductivity metal substrate .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com