Split self-circulation chemical synthesizer

A chemical synthesis and self-circulation technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of large power consumption and achieve the effects of overcoming large power consumption, reducing power consumption, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

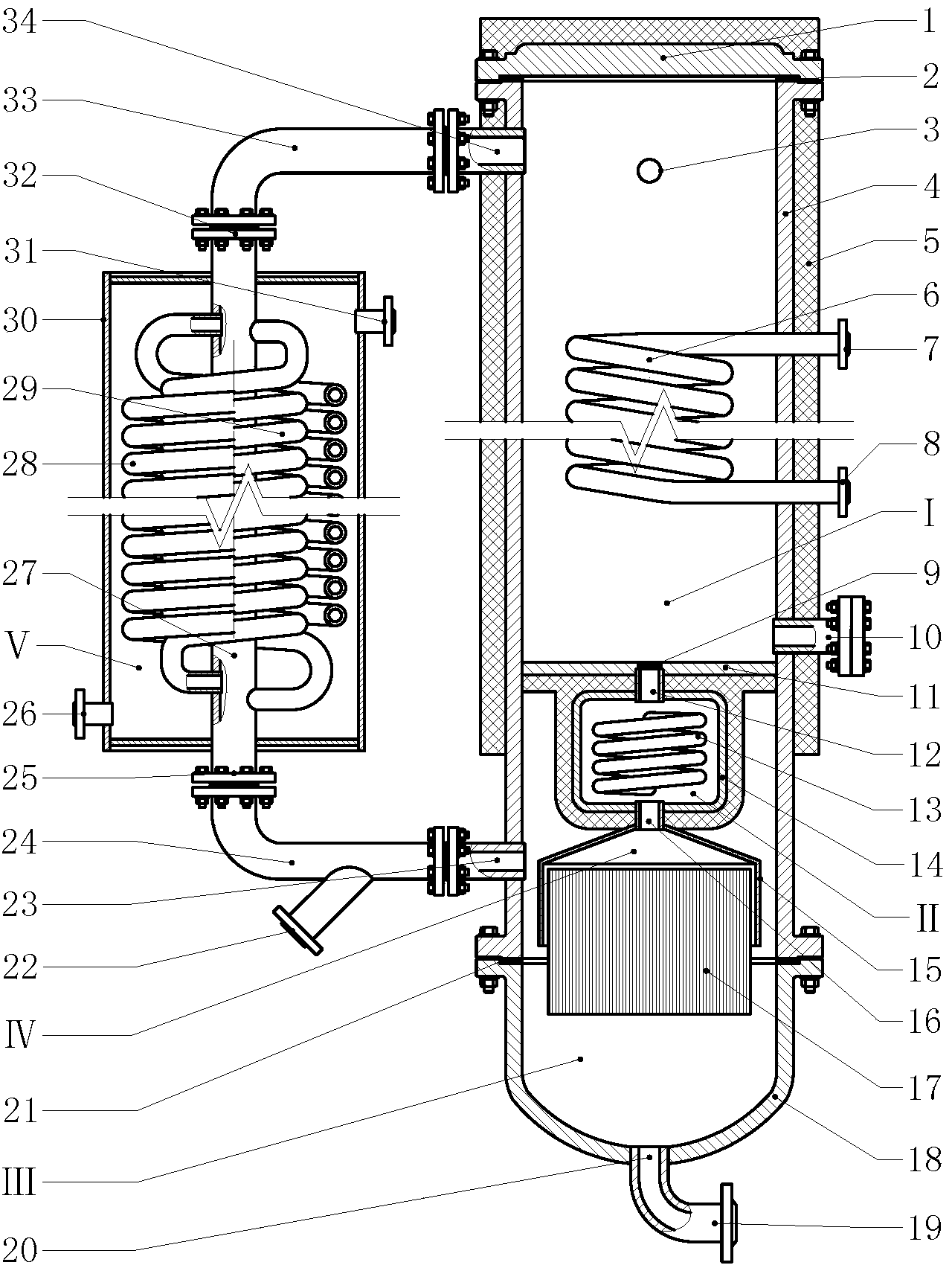

[0017] In the embodiment shown in the accompanying drawings, the split type self-circulating chemical synthesizer constitutes a self-circulating system by a heat exchanger and a reactor, wherein the heat exchanger is composed of a downcomer and a shell (30), and the inner space of the shell (30) Constitute the cooling chamber (Ⅴ), the downpipe is set in the cooling chamber (Ⅴ), the upper nozzle of the downpipe passes through the top of the cooling chamber (Ⅴ) and connects to the input interface a (32), the lower end of the downpipe The mouth passes through the bottom of the cooling chamber (Ⅴ) and is connected to the output interface a (25), the lower part of the cooling chamber (Ⅴ) has an input interface b (26) connected, and the upper part of the cooling chamber (Ⅴ) has an output interface b (31) connected; the reactor consists of an upper end (1), a wall (4), a lower end (18), a gas-liquid separator (17), a gas collection hood (15) and a preheating chamber (II), The upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com