High-strength aluminum automobile radiator

A technology of automobile radiator and radiator, which is applied in the direction of machine/engine, engine cooling, mechanical equipment, etc., can solve the problems of difficult to achieve rapid cooling of coolant, reduced strength, insufficient cooling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

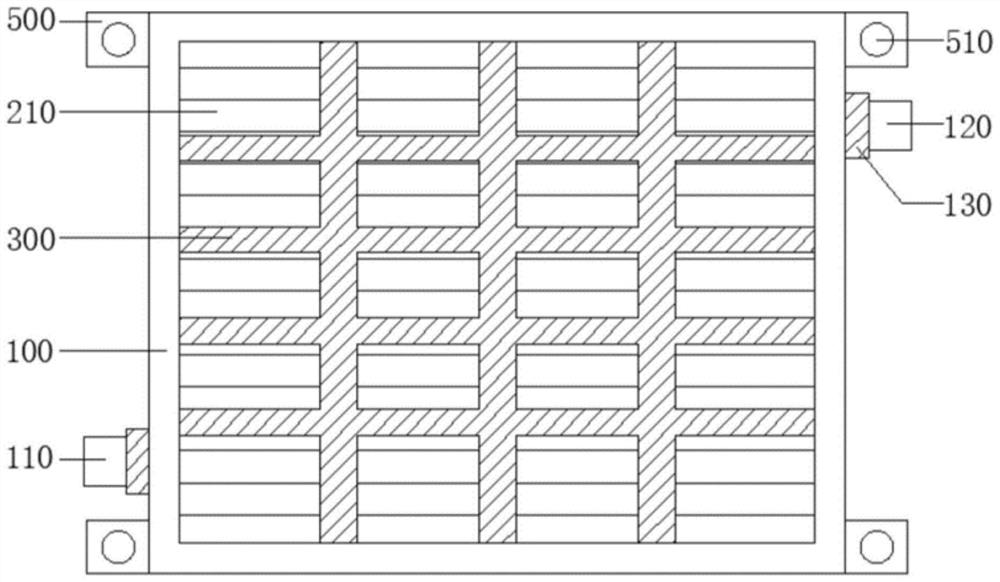

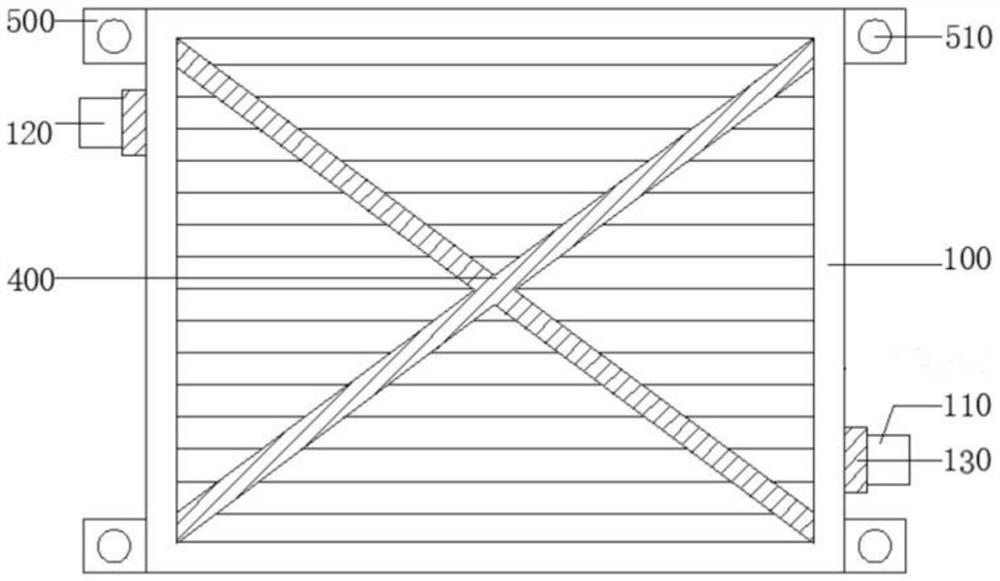

[0050] The invention provides a high-strength aluminum car radiator, which not only has higher structural strength, but also has stronger thermal conductivity, so that it can have a longer service life. Please refer to figure 1 and figure 2 , including: a high-strength aluminum automobile radiator, including a radiator shell 100, a first fixed rod 300, a second fixed rod 400 and a heat dissipation pipe 210, and the two sides of the radiator shell 100 are respectively provided with a liquid inlet 110 and a Liquid outlet 120, radiator shell 100 is fixedly installed with heat dissipation pipe 210 inside; one end of heat dissipation pipe 210 is connected with liquid inlet 110, and the other end is connected with liquid outlet 120; one side of radiator shell 100 is fixedly installed The first fixed rod 300, the first fixed rod 300 is a grid structure, the other side of the radiator shell 100 is fixedly installed with the second fixed rod 400, and the second fixed rod 400 is an X-s...

Embodiment 2

[0055] The reinforced aluminum composite material described in Example 1, calculated in parts by weight, consists of the following components:

[0056] Aluminum: 99.3 parts, silicon: 0.22 parts, copper: 0.04 parts, magnesium: 0.02 parts, zinc: 0.02 parts, manganese: 0.03 parts, vanadium: 0.02 parts, titanium: 0.02 parts, hafnium and dysprosium loaded porous carbon nanotube composite 0.018 parts, iron: 0.01 parts, unavoidable impurities ≤ 0.03 parts.

[0057] The hafnium-dysprosium-loaded porous carbon nanotube composite is obtained by loading the hafnium-dysprosium nanometer compound on the carbon nanotube porous product.

[0058] The preparation method of the carbon nanotube porous product is:

[0059] A1. Weigh bicyclocene diene nickel and add it to absolute ethanol, stir until it is completely dissolved, put in carbon nanotubes, after dispersing evenly, pour it into a reaction kettle lined with polytetrafluoroethylene, and put the reaction kettle Place it at 100-160°C for...

Embodiment 3

[0085] The reinforced aluminum composite material described in Example 1, calculated in parts by weight, consists of the following components:

[0086]Aluminum: 98.2 parts, silicon: 0.20 parts, copper: 0.02 parts, magnesium: 0.01 parts, zinc: 0.01 parts, manganese: 0.01 parts, vanadium: 0.01 parts, titanium: 0.01 parts, hafnium and dysprosium supported porous carbon nanotube composites 0.01 parts, iron: 0.001 parts, unavoidable impurities ≤ 0.03 parts.

[0087] The hafnium-dysprosium-loaded porous carbon nanotube composite is obtained by loading the hafnium-dysprosium nanometer compound on the carbon nanotube porous product.

[0088] The preparation method of the carbon nanotube porous product is:

[0089] A1. Weigh bicyclocene diene nickel and add it to absolute ethanol, stir until it is completely dissolved, put in carbon nanotubes, after dispersing evenly, pour it into a reaction kettle lined with polytetrafluoroethylene, and put the reaction kettle Place it at 100-160°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com