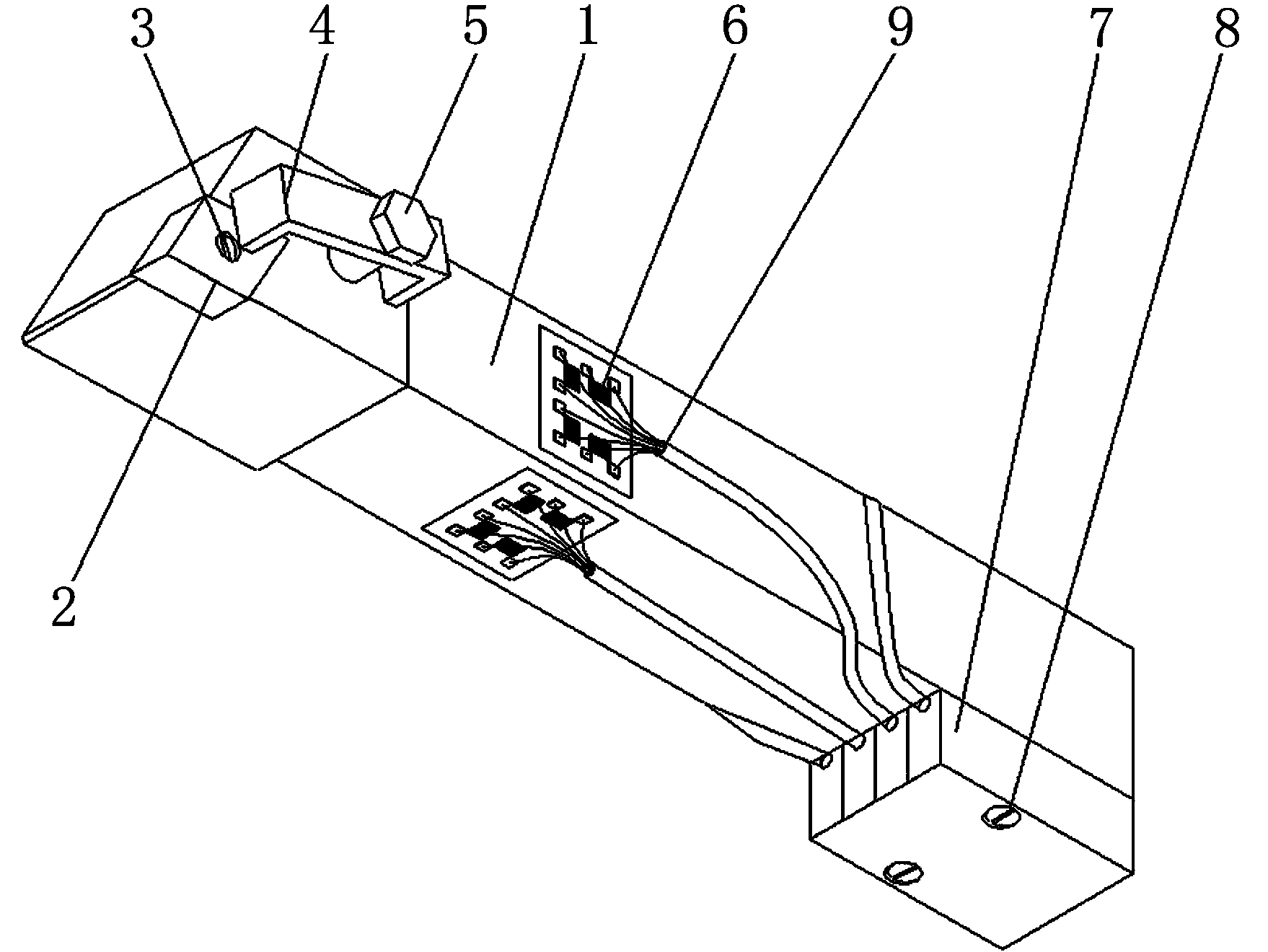

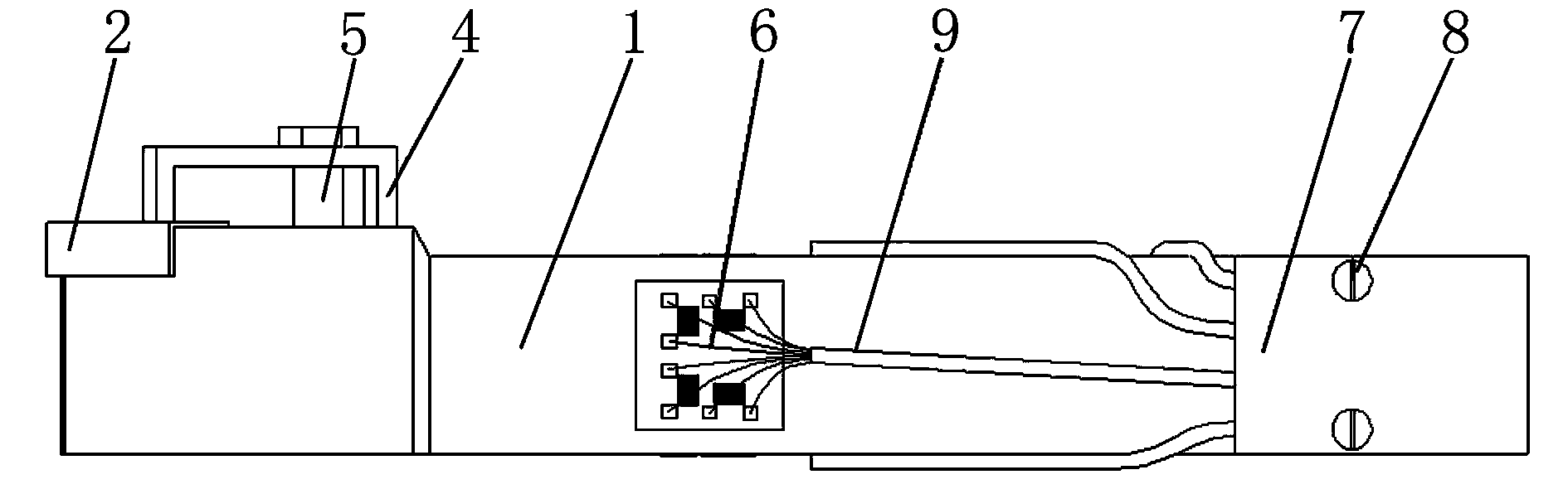

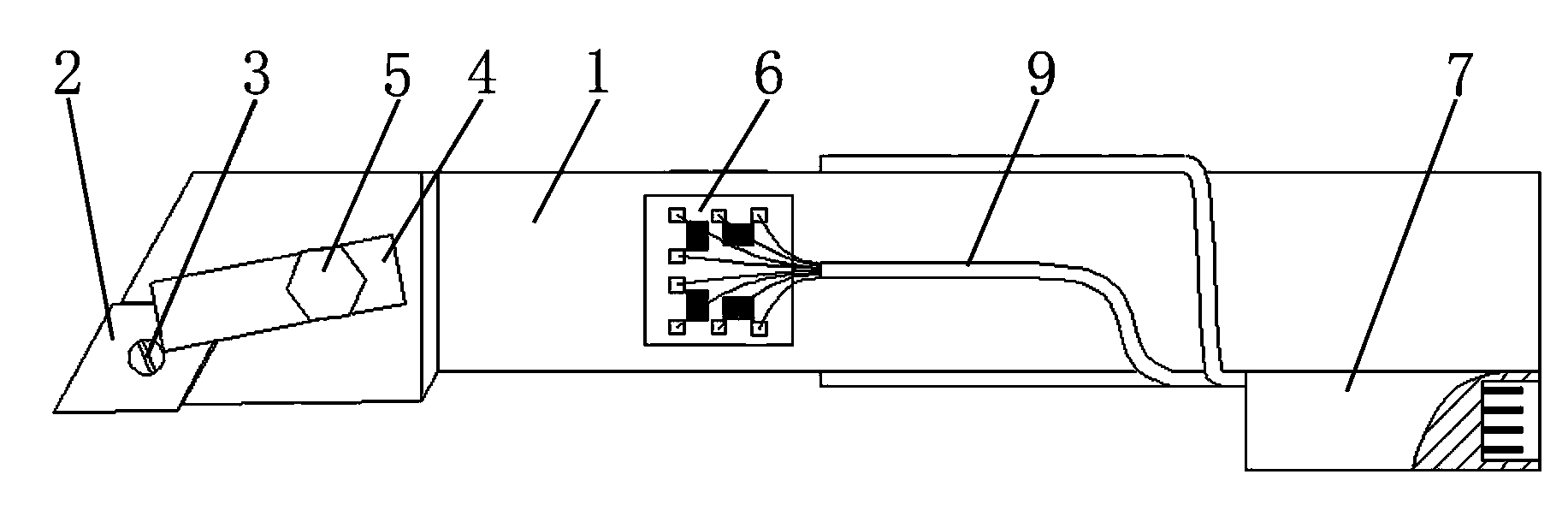

On-line measurement cutter system of cutting force of embedded thin film strain gage transducer

A strain gauge sensor and tool system technology, applied in the direction of measuring/indicating equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high manufacturing cost, complex structure, large volume of force measuring instrument, etc., and achieve reasonable structure and ingenious design , solve the effect of large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A cutting force online measuring tool system embedded with thin film strain gauge sensors, including a signal acquisition part and a signal processing part; Strain gauge sensor 6, connection terminal 7, fastening screw 8, connecting wire 9; The signal processing part includes a voltage feedback operational amplifier 10, an instrument amplifier 11, and a PC 12; wherein, the blade 2 is fastened and installed on the The front left side of the knife bar 1; the pressure plate 4 is fastened and installed on the front left side of the knife bar 1 by the fastening bolt 5, and the front right side of the pressure plate 4 is pressed against the left side of the blade 2; The thin-film strain gauge sensor 6 is fixedly installed in the middle of the side of the knife bar 1; the terminal 7 is fastened and installed on the rear lower side of the knife bar 1 by the fastening screw 8; The signal input end of terminal 7 is connected; The signal output end of connecting terminal 7 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com