Preparation method of environment-friendly diesel oil pour point depressant

A diesel pour point depressant, an environmentally friendly technology, applied in the field of preparation of environmentally friendly diesel pour point depressant, can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

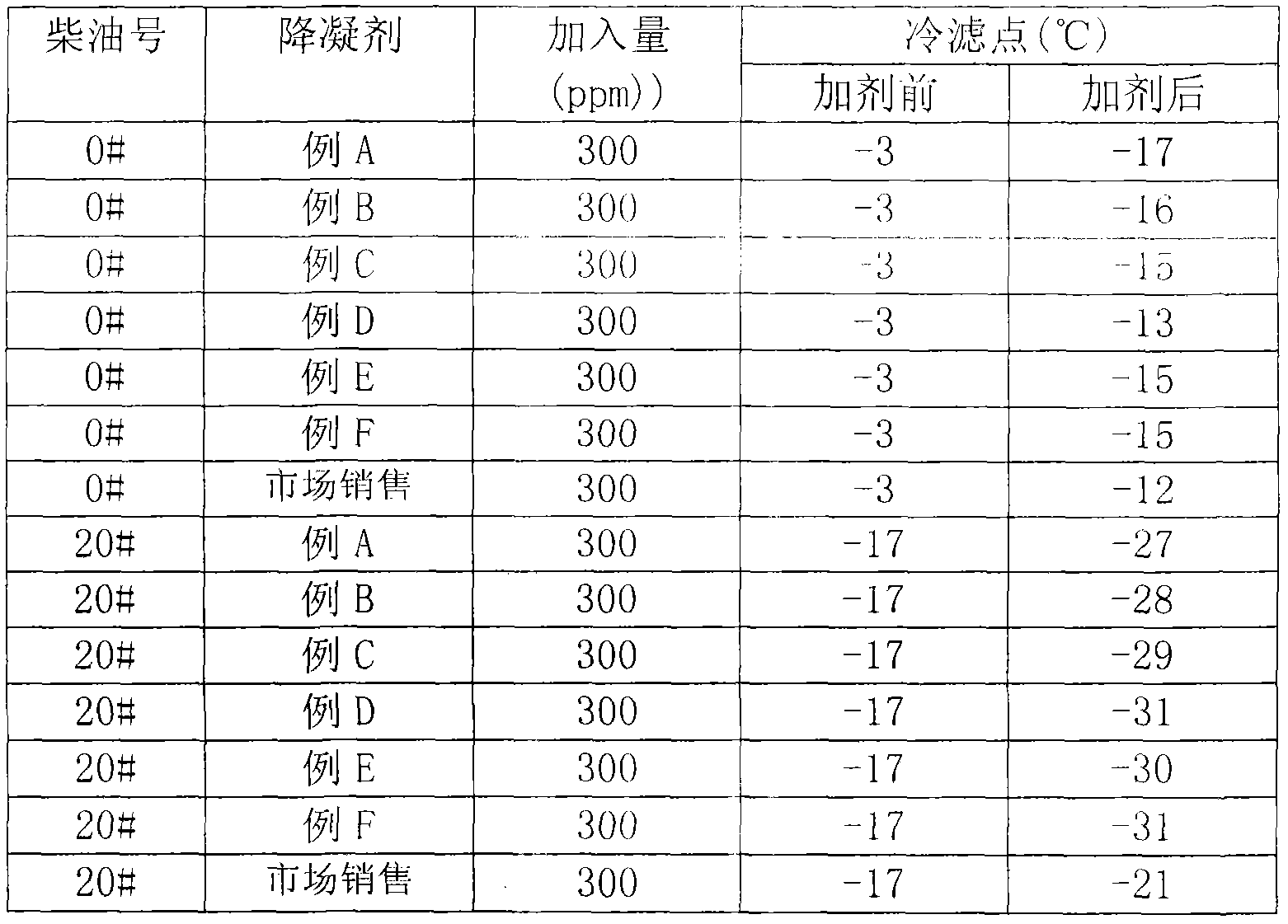

Examples

Embodiment 1

[0011] An environmentally-friendly method for preparing an environmentally friendly diesel pour point depressant. After the stainless steel autoclave is qualified by replacing it with nitrogen, the stainless steel autoclave is evacuated to a vacuum of 0.02MPa, and then the solvent cyclohexane is sucked in, followed by vinyl acetate and styrene. , 20wt% of the respective amount of initiator tert-butyl hydrogen peroxide, increase the temperature while stirring, and at the same time pass in 20wt% of the amount of ethylene monomer to reach the set reaction temperature of 100°C and pressure of 6.0MPa, then within 2 to 2.5h Pump in 80wt% of the above substances in order to control the reaction speed; react at 110℃ for 4~5h to obtain a yellow viscous liquid. After cooling, vent the ethylene and extract the reaction solution. The unreacted vinyl acetate monomer and part of the solvent are recovered by pressure distillation, the polymer is precipitated with absolute ethanol at room tempe...

Embodiment 2

[0014] An environmentally-friendly method for preparing an environmentally friendly diesel pour point depressant. After the stainless steel autoclave is qualified by replacing it with nitrogen, the stainless steel autoclave is evacuated to a vacuum of 0.02MPa, and then the solvent cyclohexane is sucked in, followed by vinyl acetate and styrene. , 20wt% of the respective amount of initiator tert-butyl hydrogen peroxide, increase the temperature while stirring, and at the same time pass in 20wt% of the amount of ethylene monomer to reach the set reaction temperature of 115°C and pressure of 7.2MPa, within 2 to 2.5 hours Pump in 80wt% of the above-mentioned substances in order to control the reaction rate; react at 115℃ for 4~5h to obtain a yellow viscous liquid. After cooling, vent the ethylene and draw out the reaction solution. The reaction solution is reduced at 0.05MPa and 60℃. The unreacted vinyl acetate monomer and part of the solvent are recovered by pressure distillation, ...

Embodiment 3

[0017] An environmentally-friendly method for preparing an environmentally friendly diesel pour point depressant. After the stainless steel autoclave is qualified by replacing it with nitrogen, the stainless steel autoclave is evacuated to a vacuum of 0.02MPa, and then the solvent cyclohexane is sucked in, followed by vinyl acetate and styrene. , 20wt% of the respective amount of initiator tert-butyl hydrogen peroxide, increase the temperature while stirring, and at the same time pass in 20wt% of the amount of ethylene monomer to reach the set reaction temperature of 120°C and pressure of 7.8MPa, and then within 2 to 2.5h Pump in 80wt% of the above-mentioned substances in order to control the reaction rate; react at a constant temperature of 120°C for 4 to 5 hours to obtain a yellow viscous liquid. After cooling, vent the ethylene and extract the reaction solution. The reaction solution is reduced at 0.05MPa and 60°C. The unreacted vinyl acetate monomer and part of the solvent a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap