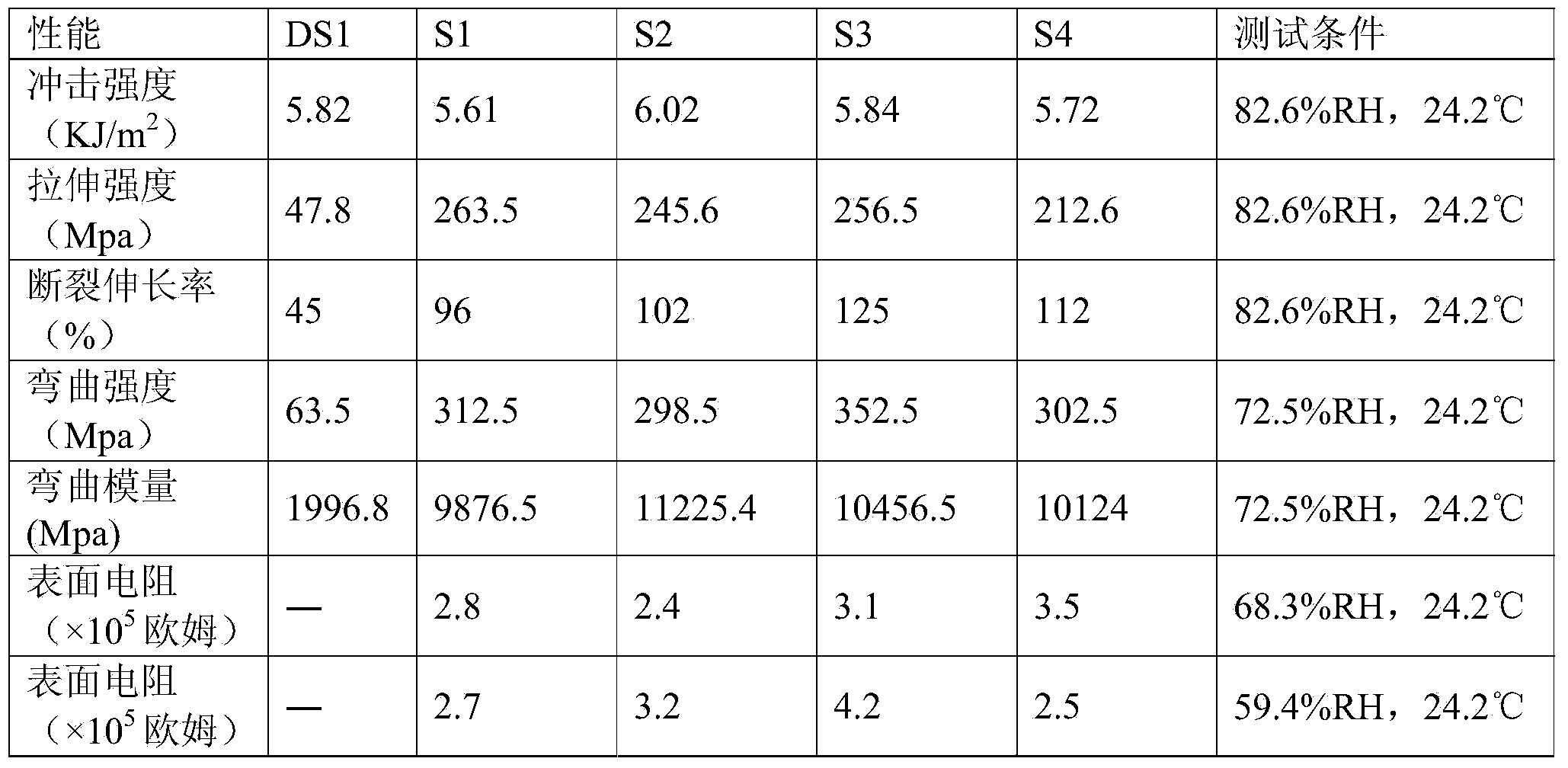

CNT (Carbon Nano Tube)/nylon6 composite material and preparation method thereof

A carbon nanotube and composite material technology, applied in the field of nylon materials, can solve the problems of low tensile strength, yield strength and flexural modulus, surface resistance, unfavorable large-scale production, unsatisfactory mechanical properties, etc., and achieves good dispersion. , high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention also provides a method for preparing a carbon nanotube / nylon 6 composite material. The steps include: preparing a modified carbon nanotube; mixing the modified carbon nanotube with nylon 6 to obtain a slurry, and then extruding to obtain a carbon nanotube Nanotube / nylon 6 composite.

[0014] Preferably, preparing the modified carbon nanotubes includes washing the carbon nanotubes with acid or hydrogen peroxide, and then treating them with a dispersant.

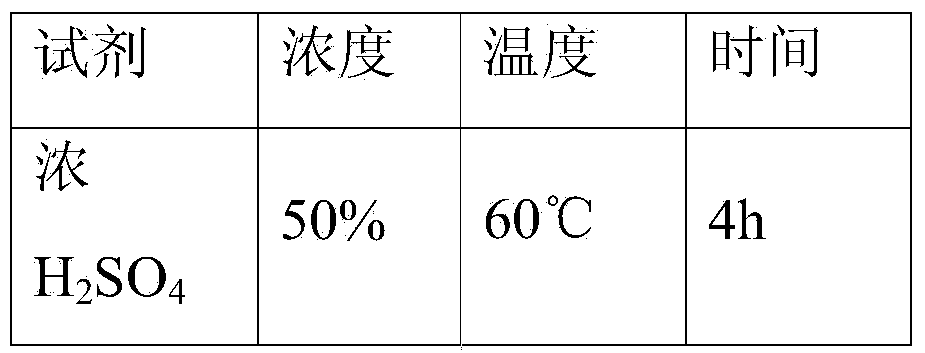

[0015] Preferably, pickling or washing with hydrogen peroxide includes immersing the carbon nanotubes in an acidic solution or hydrogen peroxide at 50-80°C for 1-24 hours; wherein, the acidic solution is selected from concentrated H with a volume concentration of 25%-75%. 2 SO 4 , Concentrated HNO with a volume concentration of 25%-75% 3 And a kind of aqua regia with a volume concentration of 25%-75%. The aqua regia includes concentrated HCL with a volume concentration of 25%-37.5% and concentrated HNO3...

Embodiment 1-4

[0025] (1) Immerse CNT dry powder in acidic solution or hydrogen peroxide for pickling or hydrogen peroxide washing. The specific acidic solution or hydrogen peroxide, specific temperature and time are as follows:

Embodiment 1

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com