Thermal management system of power battery

A technology of thermal management system and power battery, applied in the field of thermal management system, can solve problems such as battery thermal management system runaway, battery short circuit, temperature difference, etc., to increase the ambient temperature range, fast heating and cooling speed, and reduce the overall burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

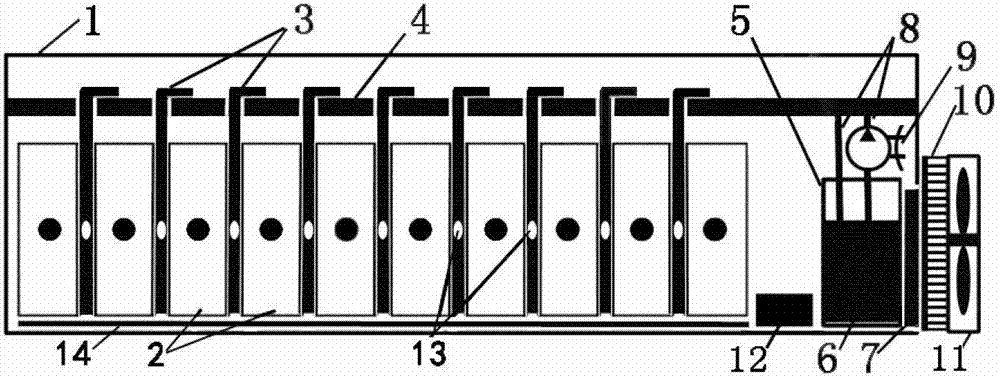

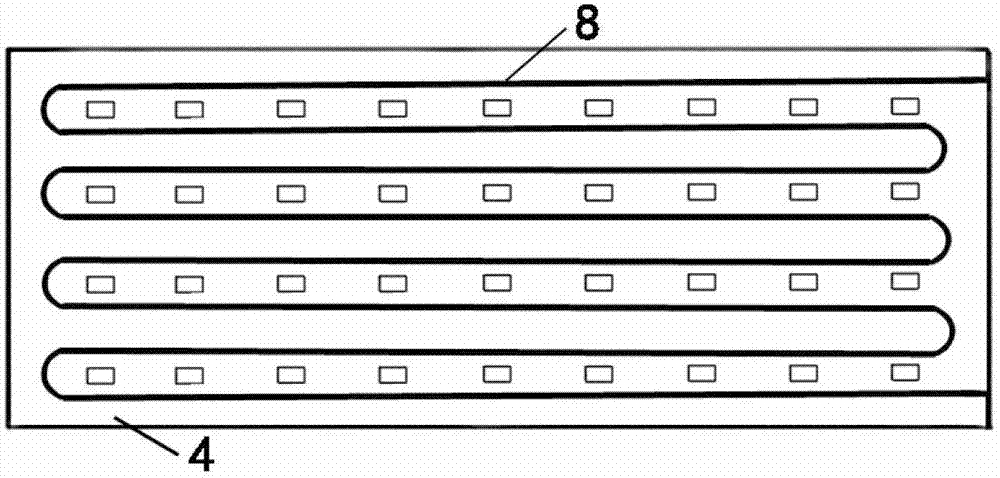

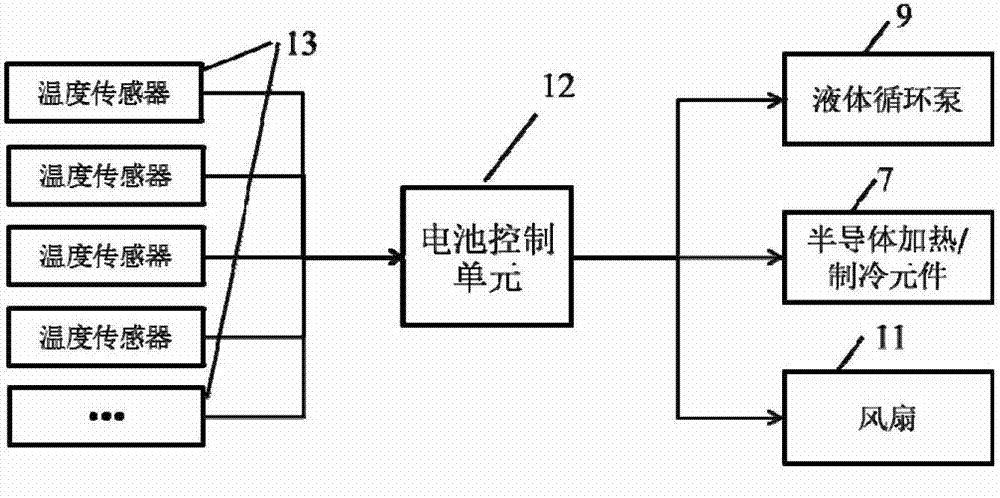

[0031] Such as figure 1 The power battery thermal management system shown is mainly composed of battery box 1, heat pipe 3, liquid flow plate 4, liquid tank 5, semiconductor heating / cooling element 7, liquid circulation pump 9, battery control unit 12, temperature sensor 13, radiator 10. The fan 11 is composed of the radiator 10 and the fan 11 installed outside the battery box 1. The radiator 10 is an aluminum alloy finned radiator, which is mainly composed of a heat conducting surface and a heat sink. The radiator 10 is installed in the battery box. On the outside, the fan 11 is installed at the best position that can be aligned with the outside of the heat sink; the heat pipe 3, the liquid flow plate 4, the liquid tank 5, the semiconductor heating / cooling element 7, the liquid circulation pump 9, the battery control unit 12 and the temperature sensor 13 Fixed in the battery box 1, battery modules 2 arranged in parallel are also installed in the battery box 1, and two heat pi...

Embodiment 2

[0036] As in the power battery thermal management system shown in Example 1, when the battery module 2 in the battery box 1 is small in size and generates less heat, or the selected heat pipe 3 has a strong heat transfer capability, under the condition that other components remain unchanged , adjust the number of heat pipes 3 inserted into the gaps between each adjacent battery module 2 , and a better heat transfer effect can be achieved by inserting one heat pipe 3 .

Embodiment 3

[0038] For the power battery thermal management system shown in Example 1, when the battery module 2 in the battery box 1 is large in size and generates a lot of heat, or the heat transfer capacity of the selected heat pipe 3 is weak, the other structural components remain unchanged. In some cases, adjust the number of heat pipes 3 inserted into the gap between each adjacent battery module 2, and insert four heat pipes 3 at even intervals to maintain a better heat transfer effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com