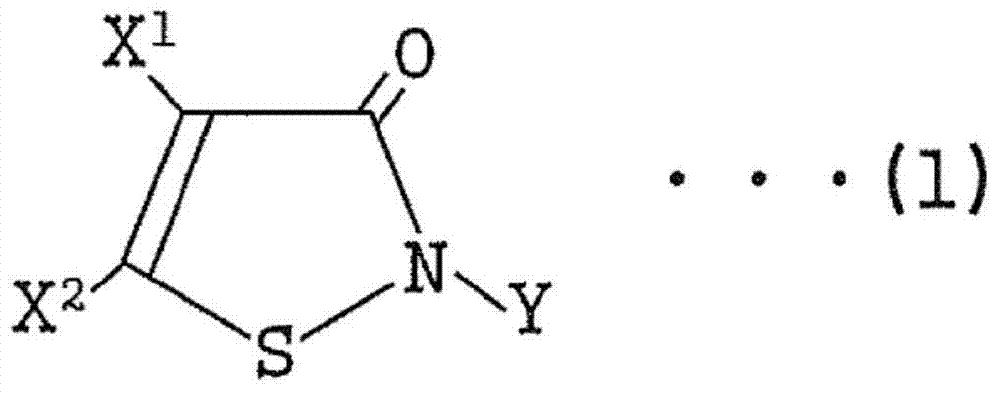

Conductive adhesive composition for electrochemical element electrode, collector with adhesive layer, and electrochemical element electrode

A technology for electrochemical components and adhesive layers, which is applied in the field of adhesive compositions for conductive adhesive layers and electrodes for electrochemical components, can solve the problems of large internal resistance and high viscosity of electrolyte, and achieve high durability , high electrode strength, strength and smooth surface state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

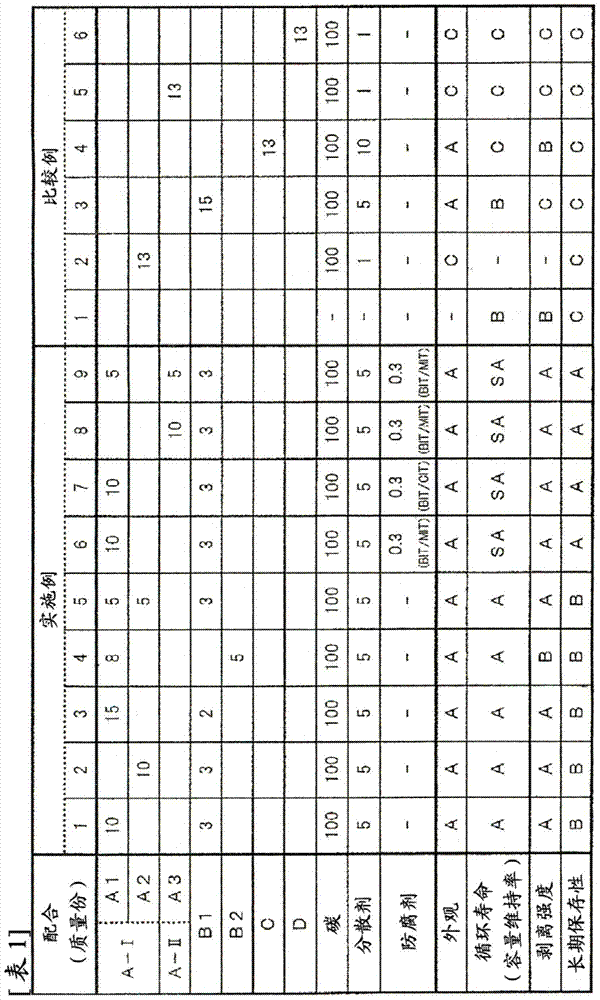

Embodiment 1~5 and comparative example 2~6

[0226] (Manufacture of conductive adhesive composition)

[0227] A carbon material (DENKA BLACK) was added to an aqueous solution obtained by dissolving a dispersant (polyvinyl alcohol) in ion-exchanged water, and after being dispersed using a bead mill at high speed for 60 minutes, the dispersion of a granular copolymer was further added, Similarly, it was rotated at a low speed for 5 minutes to disperse, and a conductive adhesive composition was prepared so as to have the solid content ratio described in Table 1. (solid content concentration 18-20%)

[0228] (Formation of conductive adhesive layer)

[0229] Coat the above-mentioned conductive adhesive on the aluminum current collector with a roll bar by casting method, apply it on both sides of the current collector at a forming speed of 20m / min, dry at 60°C for 1 minute, continue Drying was performed at 120° C. for 2 minutes to form a conductive adhesive layer with a thickness of 1.2 μm.

[0230] (production of electrode...

Embodiment 6~9

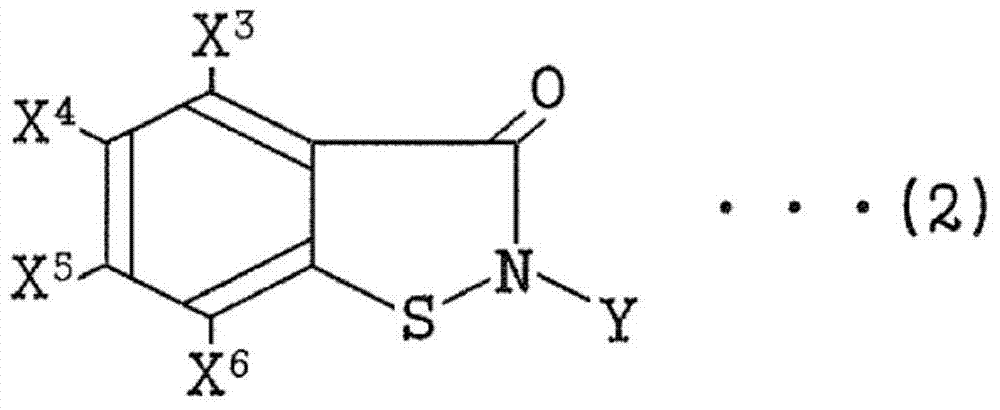

[0238] In Examples 6 to 9, an aqueous solution of an isothiazoline compound was further added to a solution obtained by dispersing a dispersant, a carbon material, and a granular copolymer, and stirred with a disperser for 30 minutes. Ratio Except having prepared a conductive adhesive composition, it carried out similarly to Example 1, and produced the electrode for lithium ion batteries, and a lithium ion battery. Table 1 shows the measurement results of each characteristic of the lithium ion battery.

[0239] In addition, the aqueous solution of the isothiazoline compound used in Examples 6, 8, and 9 was ACTICIDE (registered trademark) MBS (2-methyl-4-isothiazolin-3-one (MIT) / 1,2-Benzo-4-isothiazolin-3-one (BIT) = 50 / 50 in 5% aqueous solution).

[0240] Alternatively, ACTICIDE (registered trademark) 5008 (5-chloro-2-methyl-4-isothiazolin-3-one (CIT) / 2-methyl-4-isothiazolin-3-one (CIT) manufactured by So Japan Ketone (MIT)=50 / 50 5% aqueous solution) instead of ACTICIDE (re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com