Preparation method of canned fish

A technology of canned fish and fish body, which is applied in the field of food processing, can solve the problems of single species, scattered fish body tissue, fragments affecting the senses, etc., and achieve the effects of reducing nutrient loss, reducing peroxide value, and reducing fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

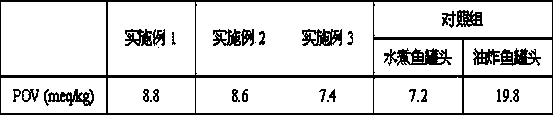

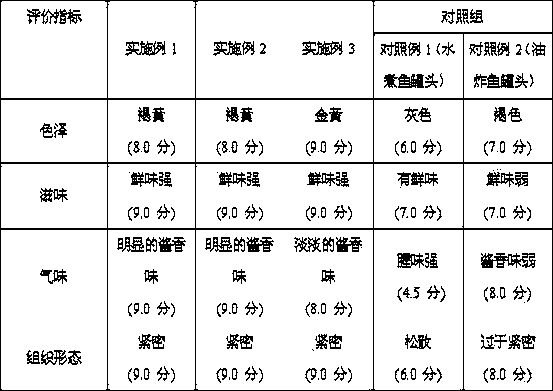

Embodiment 1

[0022] After removing the head, scales, viscera and black film of about 1kg of blue round trevally, add 3L of salt water with a weight volume ratio of 10%, soak and rinse at 5°C for 30 minutes, drain and put Soak in 1% (w / v) Torulopsis globosa solution for 2 min, drain, then transfer to 28°C constant temperature and humidity box (humidity is 40%) to ferment for 36 hours, and then use a drying box to dry at 50°C Dry for 8 hours, and finally use a baking oven to bake at 200°C for 8 minutes, put them into glass cans, about 120 g per can, add seasonings and hot oil at 80°C, seal the cans immediately, and prepare For canned fish products, sensory evaluation and peroxide value determination were carried out on the products (after being placed at 37°C for one month).

Embodiment 2

[0024] About 1 kg of small yellow croaker, after removing the head, scale, viscera and black film, add 5L of salt water with a weight volume ratio of 12%, soak and rinse at 10°C for 20 minutes, drain, and put it in a container containing 3 % (w / v) of Torulopsis globosa solution for 1.5 min, drained, and then transferred to a 30°C constant temperature and humidity box (humidity is 30%) to ferment for 24h, and then dried at 60°C in a drying box for 6 h, trim to appropriate specifications, and finally use the oven to bake at 180°C for 10 minutes, put them into glass jars, about 120 g per jar, add seasonings and hot oil at 85°C, and seal the jars immediately , prepared into canned fish products, and the products were subjected to sensory evaluation and peroxide value determination (after being placed at 37° C. for one month).

Embodiment 3

[0026] About 1kg of tilapia, after removing the head, scale, viscera and black film, add 5L of salt water with a weight volume ratio of 15%, soak and rinse at 10°C for 15 minutes, drain and put Soak in 5% (w / v) yeast solution for 1 min, drain, then transfer to a 35°C constant temperature and humidity box (humidity is 20%) to ferment for 18h, and then use a drying box at 70°C Dry for 4 hours, trim to appropriate specifications, and finally use a baking oven to bake at 150°C for 12 minutes, put them into tinplate cans, each can is about 120 g, add seasonings and 90°C hot oil, and immediately The cans were sealed and prepared into canned fish products, and the products were subjected to sensory evaluation and peroxide value determination (after being placed at 37° C. for one month).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com