Multifunctional guanidine salt grafted carboxymethyl cellulose paper-making additive and preparation method thereof

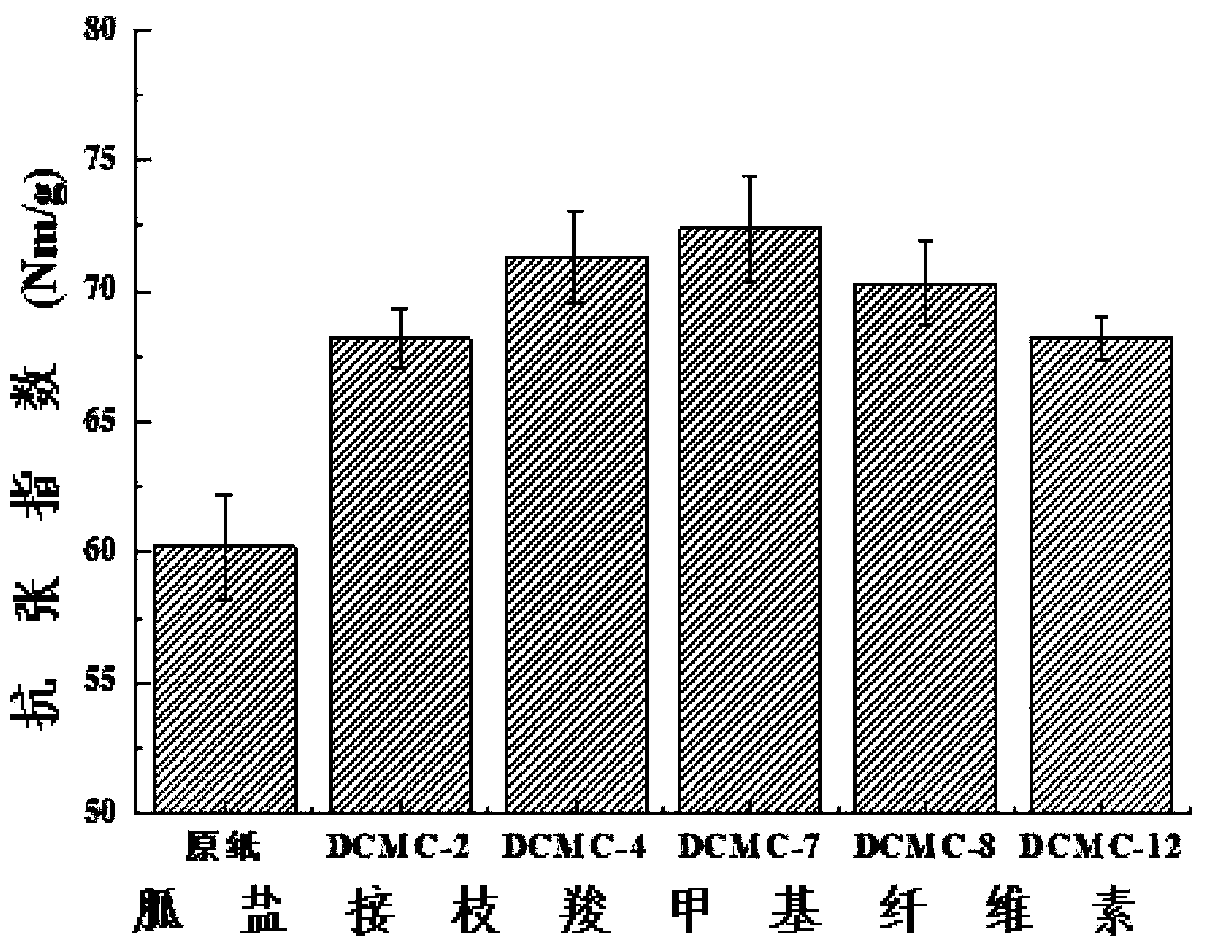

A technology of carboxymethyl cellulose and paper-making additives, applied in the field of guanidinium salt-grafted carboxymethyl cellulose multifunctional paper-making additives and its preparation, can solve the problems of harming health, no antibacterial effect, and bacterial growth, etc. Achieve the effects of reducing production costs, high-efficiency antibacterial properties, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

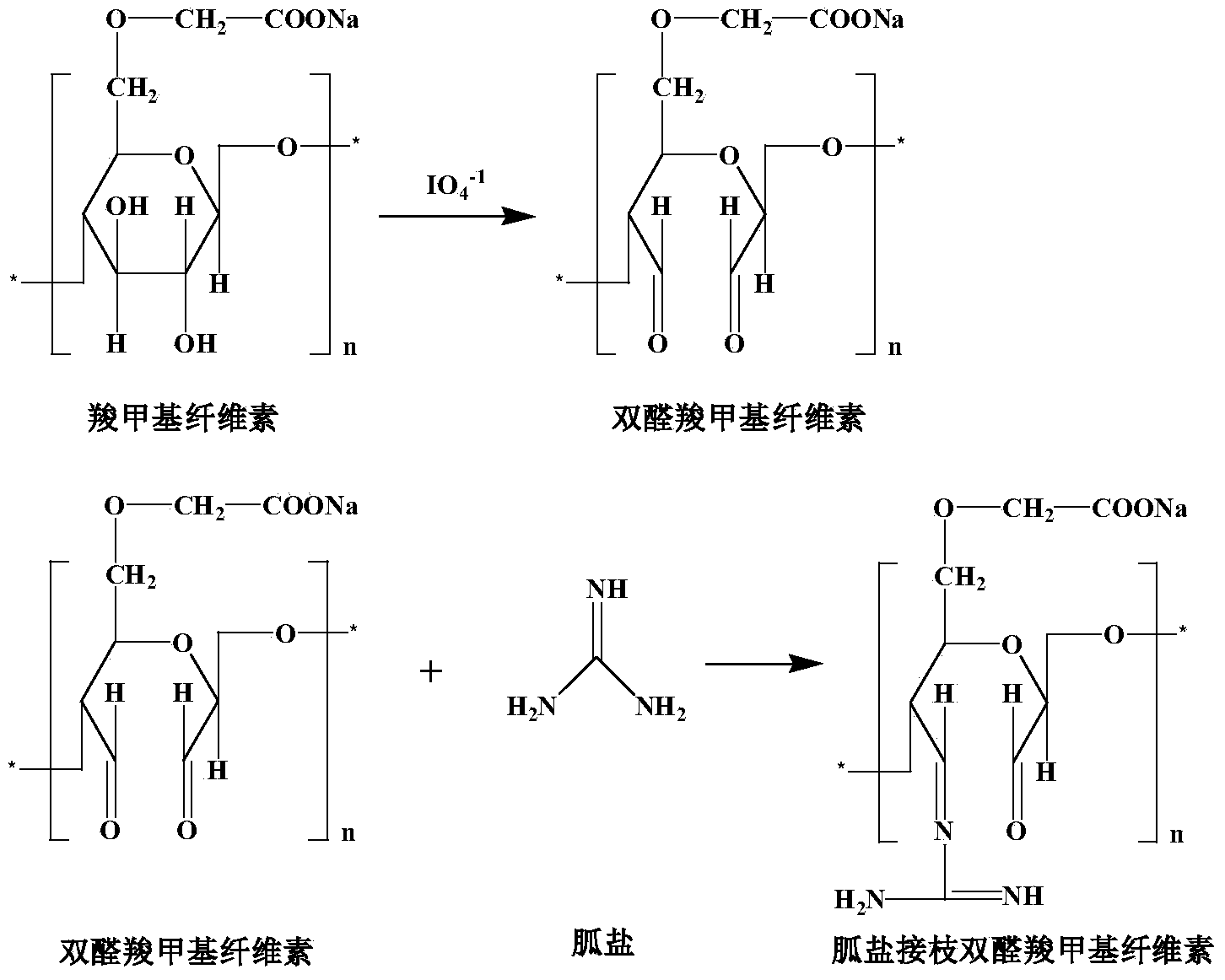

[0018] (1) Add carboxymethyl cellulose to 1 mol / L sodium periodate solution, heat and react at 30°C for 6h, filter, wash and dry the product to obtain dialdehyde carboxymethyl cellulose; The molar ratio of sodium periodate to carboxymethyl cellulose is 1:1.

[0019] (2) Disperse the dialdehyde carboxymethyl cellulose obtained in step (1) in distilled water, add guanidine hydrochloride and react at 30°C for 4 hours, filter, wash and dry the product to obtain guanidinium salt grafted carboxymethyl fiber Plain; The mol ratio of described guanidinium salt and bisaldehyde carboxymethyl cellulose is 1:1.

Embodiment 2

[0021] (1) Add carboxymethyl cellulose to 1.5 mol / L sodium periodate solution, heat and react at 40°C for 6h, filter, wash and dry the product to obtain dialdehyde carboxymethyl cellulose; The molar ratio of sodium periodate to carboxymethyl cellulose is 1:1.2.

[0022] (2) Disperse the dialdehyde carboxymethyl cellulose obtained in step (1) in distilled water, add guanidine hydrochloride and react at 50°C for 4 hours, filter, wash and dry the product to obtain guanidinium salt grafted carboxymethyl fiber Plain; The mol ratio of described guanidinium salt and bisaldehyde carboxymethyl cellulose is 1:5.

Embodiment 3

[0024] (1) Add carboxymethyl cellulose to 2 mol / L sodium periodate solution, heat and react at 50°C for 6h, filter, wash and dry the product to obtain dialdehyde carboxymethyl cellulose; The molar ratio of sodium periodate to carboxymethyl cellulose is 1:1.5.

[0025] (2) Disperse the dialdehyde carboxymethyl cellulose obtained in step (1) in distilled water, add metformin hydrochloride and react at 60°C for 4 hours, filter, wash and dry the product to obtain guanidinium salt grafted carboxymethyl fiber Plain; The mol ratio of described guanidinium salt and bisaldehyde carboxymethyl cellulose is 1:10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com