In-Situ Organic Modification-Pre-expansion Preparation Method of Rubber/Clay Nanocomposites

A technology of nano-composite materials and organic modifiers is applied in the field of new preparation of rubber and clay nano-composite materials, which can solve problems such as poor reinforcement ability, and achieve the effects of avoiding waste, reducing pollution and improving dispersion structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

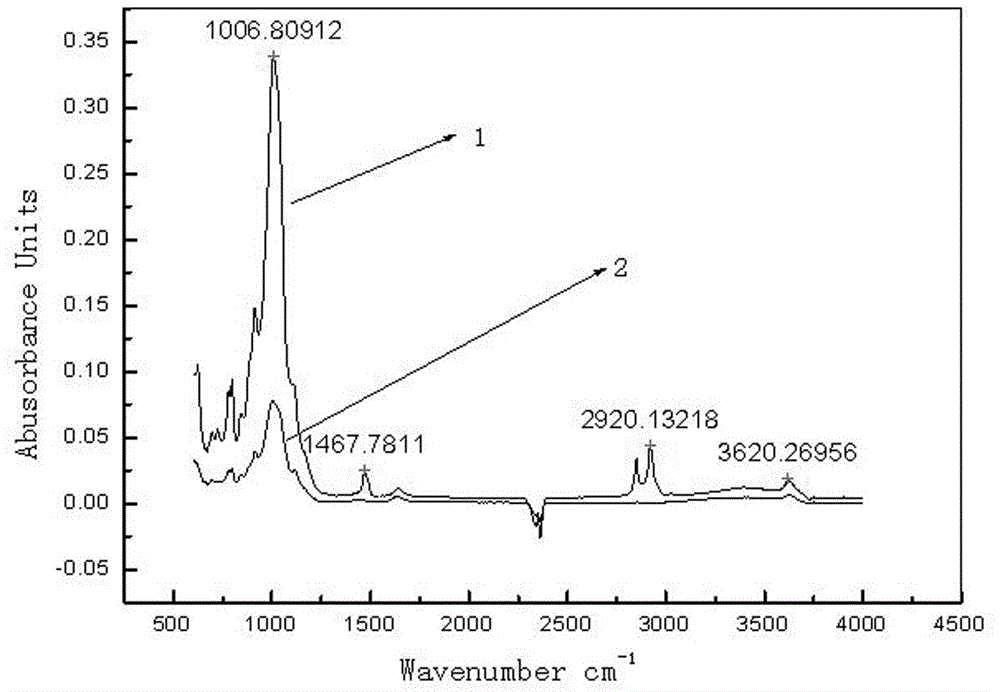

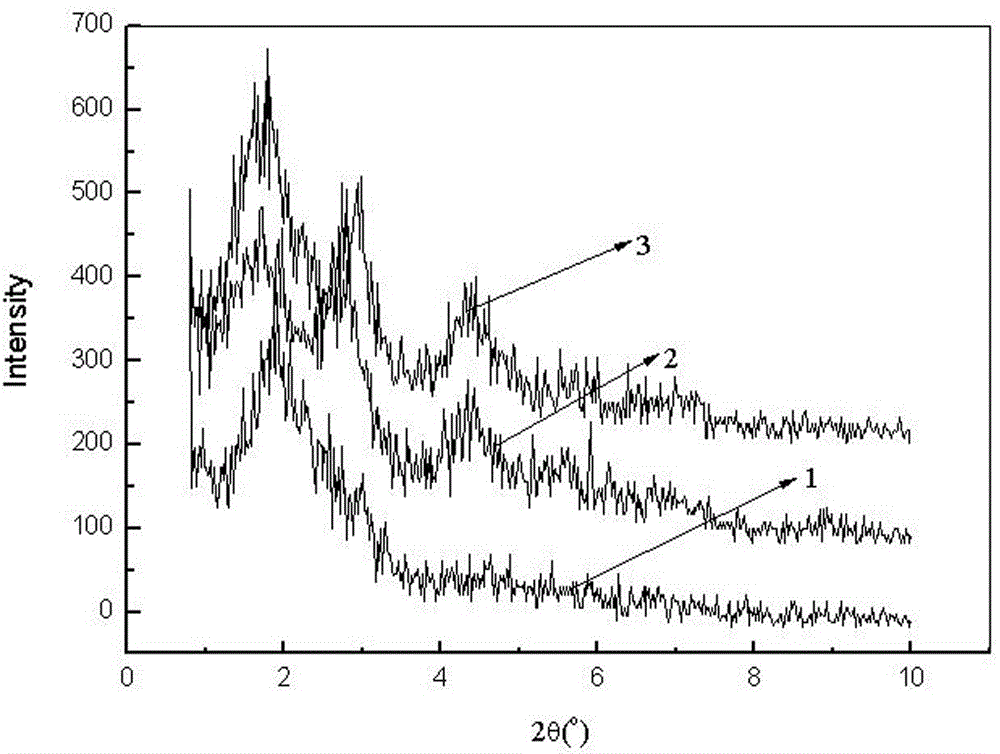

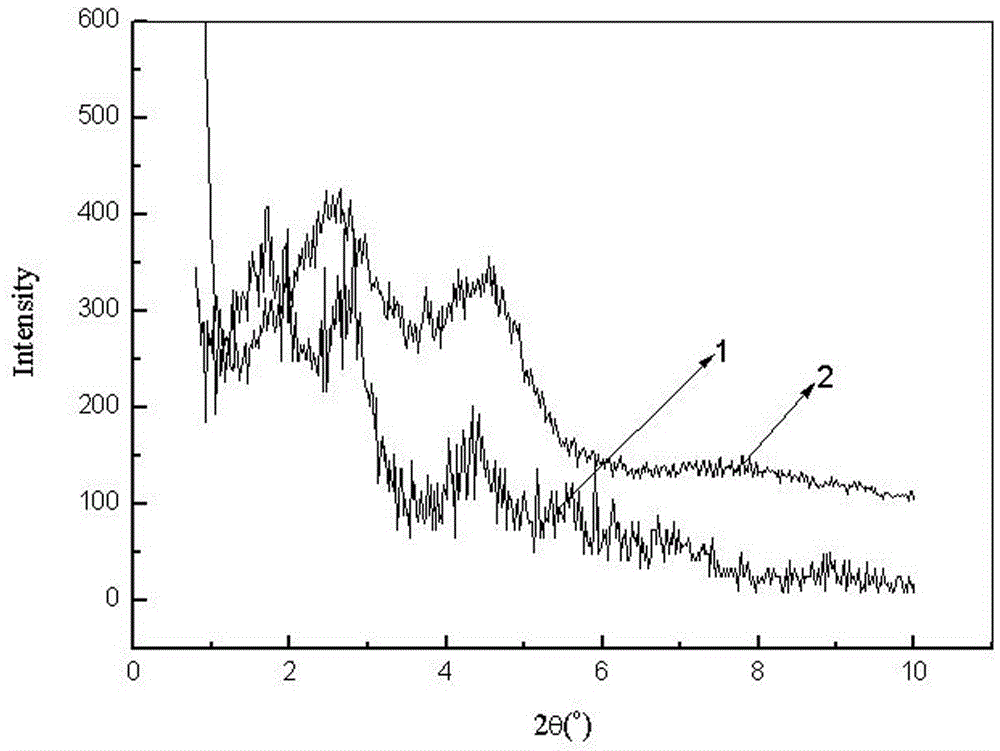

Image

Examples

Embodiment 1

[0046] Mix inorganic clay, cetyltrimethylammonium bromide and n-butanol uniformly in a certain proportion; the mass ratio of inorganic clay to cetyltrimethylammonium bromide is 2.8g:1g, and inorganic clay and n-butanol The mass ratio of butanol is 10g:2.4g (wherein the mass fraction of n-butanol in the prepared in-situ organic soil is 15% or ω 正丁醇 =15%, the same below); the mixed soil was left to stand for 1 hour; the above-mentioned mixed clay was ground in a three-roller mill for 5 minutes to obtain an in-situ organically modified and pre-expanded organoclay (referred to as in-situ organoclay) for future use. Mix 100 parts of nitrile rubber and 10 parts of in-situ organoclay on a double-roller mill for 30 minutes, then add the following compounding agents in three steps, the first step is to add 5 parts of zinc oxide and 1 part of stearic acid; In the second step, add 1.5 parts of dibenzothiazole disulfide (accelerator), 2.0 parts of N-isopropyl-N'-phenyl-p-phenylenediamine ...

Embodiment 2

[0048] Change the mass ratio of inorganic clay to n-butanol to 10g:3.4g (ω 正丁醇 =20%), the rest of the operation steps are the same as in Example 1, and finally the nitrile rubber / clay nanocomposite material is obtained, and its mechanical properties are shown in Table 1.

Embodiment 3

[0050] Change the mass ratio of inorganic clay to n-butanol to 10g:5.9g (ω 正丁醇 =30%), the rest of the operation steps are the same as in Example 1, and finally the nitrile rubber / clay nanocomposite material is obtained, and its mechanical properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com