Polyester microporous separator for secondary lithium battery and preparation method thereof

A technology for secondary lithium batteries and microporous separators, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high thermal shrinkage rate and decreased air permeability, and achieve simple production process and low high temperature thermal shrinkage rate. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

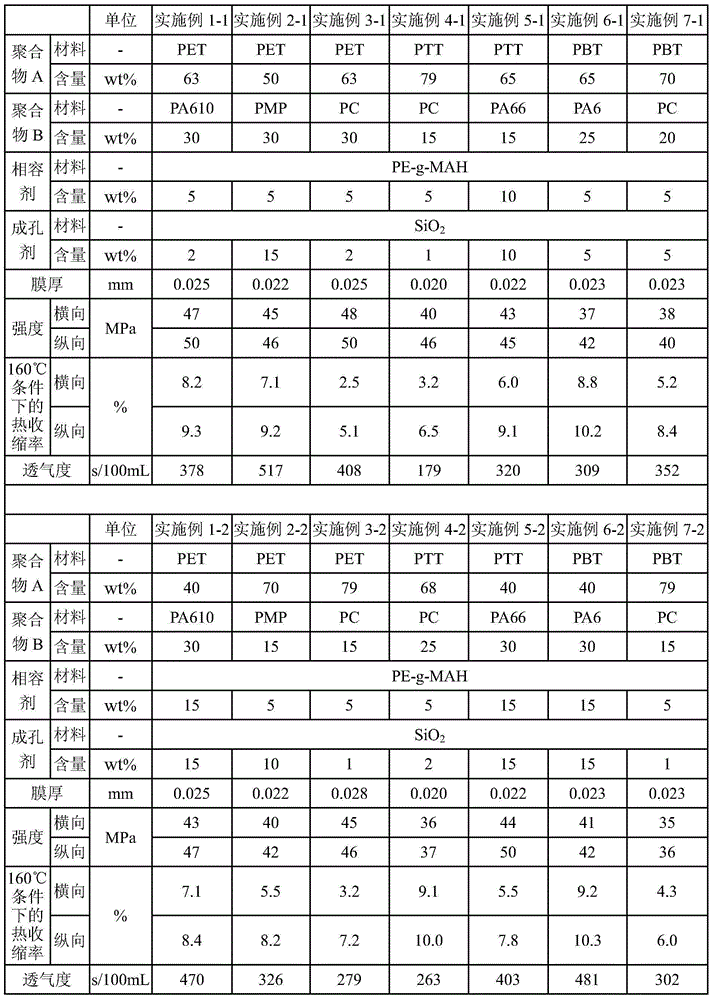

Embodiment 1-1、1-2

[0033] After drying the components with a certain proportion in Table 1 under different conditions, the twin-screw extruder was melted and kneaded at 280°C and then extruded and cut into granules, and the obtained granules were dried again to After the moisture content is 200ppm, put it into a single-screw extruder to melt, knead and extrude it at 280°C, cool it with a cold drum at 20°C-40°C and cast it into a thick sheet with a thickness of 0.2-0.3mm. After stretching 2 times in the longitudinal direction at 135°C, preheat in the drying tunnel at 135°C, perform simultaneous biaxial stretching at 135°C, stretch 2 times in the longitudinal direction and 2.5 times in the transverse direction, and then heat-setting at 135°C , to obtain a polyester microporous separator.

Embodiment 2-1、2-2

[0035] After drying the components with a certain proportion in Table 1 under different conditions, the twin-screw extruder melted and kneaded at 275 ° C and then extruded and cut into granules, and the obtained granules were dried again to After the moisture content is 200ppm, put it into a single-screw extruder to melt, knead and extrude it at 275°C, then cool it with a cold drum at 20°C to 40°C and cast it into a thick sheet with a thickness of 0.2 to 0.3mm. After stretching 2 times in the longitudinal direction at low temperature, it is preheated through the drying tunnel at 110°C, and then the biaxial stretching is carried out simultaneously at 110°C, stretching 2 times in the longitudinal direction and 3 times in the transverse direction, and then heat-setting at 145°C. A polyester microporous separator was obtained.

Embodiment 3-1、3-2

[0037] After drying the various components with a certain proportion and number given in Table 1 under different conditions, the twin-screw extruder melted and kneaded at 285 ° C and then extruded and cut into granules, and the obtained granules were dried again to After the moisture content is 200ppm, put it into a single-screw extruder to melt, knead and extrude at 285°C, cool it with a cold drum at 20°C to 40°C and cast it into a thick sheet with a thickness of 0.2 to 0.3mm. After stretching 2 times in the longitudinal direction at 115°C, preheat the drying tunnel at 115°C, perform simultaneous biaxial stretching at 115°C, stretch 2 times in the longitudinal direction and 2.8 times in the transverse direction, and then heat-setting at 150°C. A polyester microporous separator was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com