Fibre compound temporary plugging agent

A technology of fiber composite and temporary plugging agent, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of formation damage, complicated construction, and difficult to disperse, and achieves less damage, good plugging effect, and improved strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of fiber composite temporary plugging agent, it is made up of the raw material of following parts by weight: carrying liquid 55, temporary plugging agent particle 20, temporary plugging fiber 0.5;

[0024] The carrier liquid is composed of the following raw materials in parts by weight: 0.2 guar gum, 0.1 bactericide, 0.3 viscosity stabilizer, 0.3 drainage aid, and 0.1 sodium carbonate;

[0025] The temporary plugging agent particles are sodium stearate, and meet the following requirements:

[0026] A. Particle size of temporary plugging agent: 20 mesh accounts for 30%, 60 mesh accounts for 60%, and 100 mesh accounts for 10%;

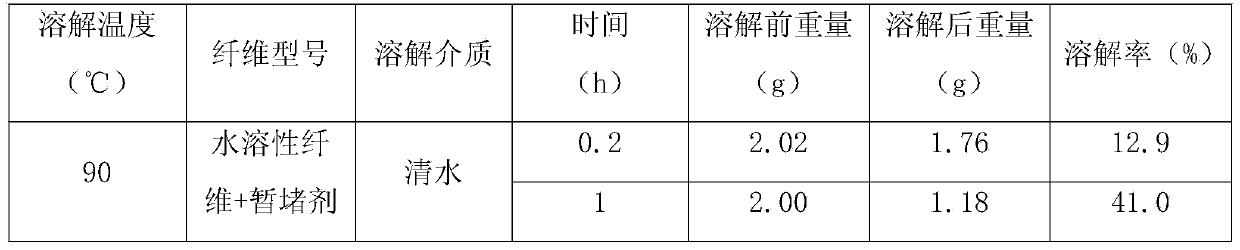

[0027] B. Dissolution properties of temporary plugging agent particles: soluble in aqueous solution above 50°C, the dissolution time is greater than 30 minutes, and the dissolution rate is greater than 95%;

[0028] The temporary plugging fiber is polyvinyl alcohol fiber and meets the following requirements:

[0029] C. Fibe...

Embodiment 2

[0033] Embodiment 2: a fiber composite temporary plugging agent, which is composed of the following raw materials in parts by weight: carrier liquid 75, temporary plugging agent particles 30, temporary plugging fiber 2;

[0034] The carrier liquid is composed of the following raw materials in parts by weight: 0.6 guar gum, 0.5 bactericide, 0.7 viscosity stabilizer, 0.8 drainage aid, and 0.5 sodium carbonate;

[0035] The temporary plugging agent particles are acrylic resin and polyvinyl alcohol, the weight ratio is 1:2, and meet the following requirements:

[0036] A. Particle size of temporary plugging agent: 160 mesh accounts for 65%, 100 mesh accounts for 30%, and 80 mesh accounts for 5%;

[0037] B. Dissolution properties of temporary plugging agent particles: at a temperature above 50°C, it is soluble in 5% hydrochloric acid, the dissolution time is greater than 30 minutes, and the dissolution rate is greater than 95%;

[0038] The temporary plugging fiber is modified po...

Embodiment 3

[0043] Embodiment 3: a kind of fiber composite temporary plugging agent, it is made up of the raw material of following weight part:

[0044] Carrying fluid 60, temporary plugging agent particles 24, temporary plugging fiber 0.8;

[0045] The carrier fluid is composed of the following raw materials in parts by weight: 0.4 guacamole, 0.3 bactericide, 0.5 viscosity stabilizer, 0.5 drainage aid, and 0.3 sodium carbonate;

[0046] The temporary plugging agent particles are sodium stearate, acrylic resin and calcium carbonate, the weight ratio is 1:2:1, and meet the following requirements:

[0047] A. Particle size of temporary plugging agent: 160 mesh 80%, 140 mesh 10%, 40 mesh 10%;

[0048] B. Dissolution properties of temporary plugging agent particles: soluble in aqueous solution above 50°C, the dissolution time is greater than 30 minutes, and the dissolution rate is greater than 95%;

[0049] The temporary plugging fiber is polyvinyl alcohol fiber, modified polyester fiber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com