Al-Fe-Cu-Mg aluminum alloy and medium-voltage cable prepared from Al-Fe-Cu-Mg aluminum alloy

An al-fe-cu-mg, aluminum alloy technology, used in power cables with shielding/conducting layers, metal/alloy conductors, cable/conductor manufacturing, etc., can solve the problem of fatigue resistance and creep resistance. issues such as improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

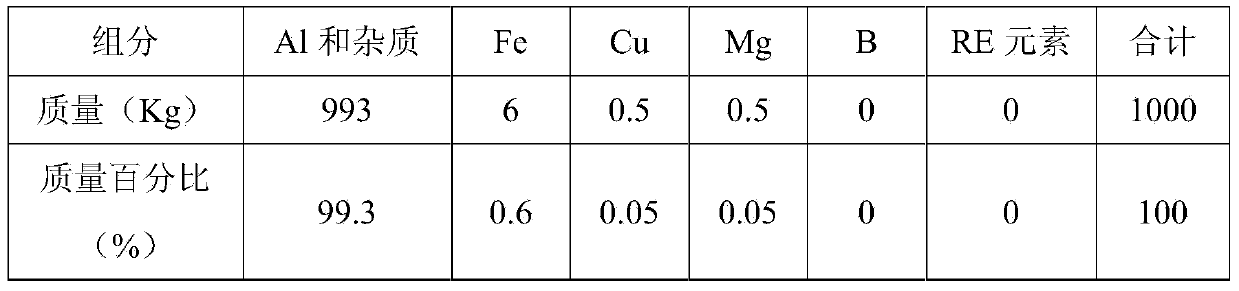

[0060] An Al-Fe-Cu-Mg aluminum alloy, wherein the components and component contents are shown in the following table

[0061]

[0062] The specific method for preparing the aluminum alloy conductor material by using the above aluminum alloy formula is as follows:

[0063] a) Melting is carried out by adding various components according to the above proportions in a constant temperature cupola at 800°C;

[0064] b) The molten metal after smelting is added to the 750°C holding furnace in proportion to the refining agent, and the high-temperature-resistant alloy steel double-blade stirrer is used to stir at a rate of 20 rpm for 10 minutes. After the stirring, the temperature is raised to 820°C and kept for 30 minutes. minute;

[0065] c) The alloy liquid is cooled to below 650°C through a constant temperature diversion tank (set temperature 645°C) and then enters the casting room for casting;

[0066] d) cooling the cast bar obtained in step c) to 400° C. for 4 hours after b...

Embodiment 2

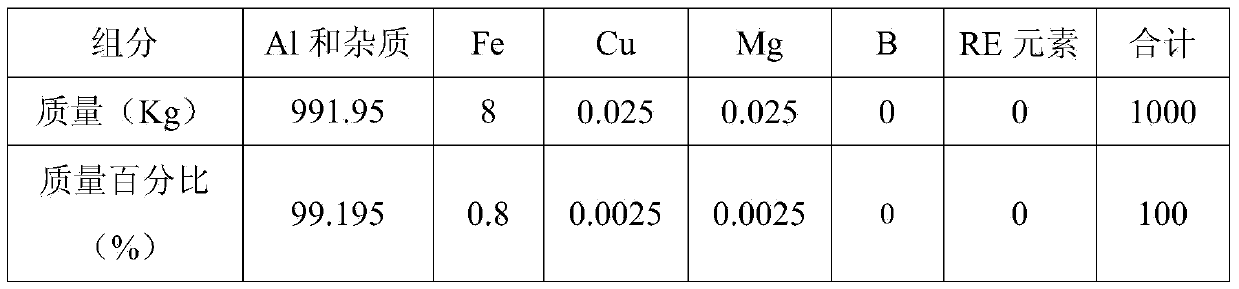

[0078] An Al-Fe-Cu-Mg aluminum alloy, wherein the components and component contents are shown in the following table

[0079]

[0080] The specific method for preparing the aluminum alloy conductor material by using the above aluminum alloy formula is as follows:

[0081] a) Melting is carried out by adding various components in the above ratio in a constant temperature cupola at 780°C;

[0082] b) The molten metal after smelting is added to the 750°C holding furnace in proportion to the refining agent, and the high-temperature-resistant alloy steel double-blade stirrer is used to stir at a rate of 20 rpm for 10 minutes. After the stirring, the temperature is raised to 820°C and kept for 30 minutes. minute;

[0083] c) The alloy liquid is cooled to below 650°C through a constant temperature diversion tank (set temperature 645°C) and then enters the casting room for casting;

[0084] d) cooling the cast bar obtained in step c) to 400° C. for 4 hours after being kept at 480...

Embodiment 3

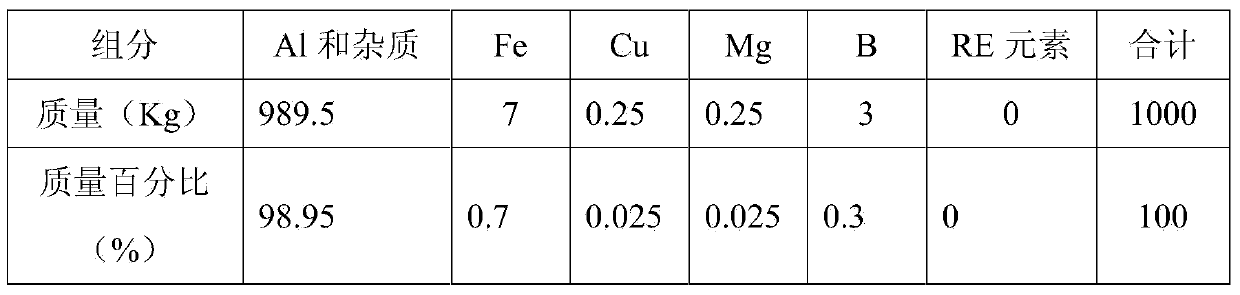

[0097] An Al-Fe-Cu-Mg aluminum alloy, wherein the components and component contents are shown in the following table

[0098]

[0099] The specific method for preparing the aluminum alloy conductor material by using the above aluminum alloy formula is as follows:

[0100] a) Melting is carried out by adding various components according to the above proportions in a constant temperature cupola at 850°C;

[0101] b) The molten metal after smelting is added to the 750°C holding furnace in proportion to the refining agent, and the high-temperature-resistant alloy steel double-blade stirrer is used to stir at a rate of 20 rpm for 10 minutes. After the stirring, the temperature is raised to 820°C and kept for 30 minutes. minute;

[0102] c) The alloy liquid is cooled to below 650°C through a constant temperature diversion tank (set temperature 645°C) and then enters the casting room for casting;

[0103] d) cooling the cast bar obtained in step c) to 400° C. for 4 hours after b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com