A Buckling-Resistant Brace Member of Split Double Rectangular Tube Section

A buckling-resistant support and separate technology, which is applied in the direction of building components, earthquake resistance, building construction, etc., can solve problems such as reduced shear stiffness, increased bending deformation of components, and overall instability of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

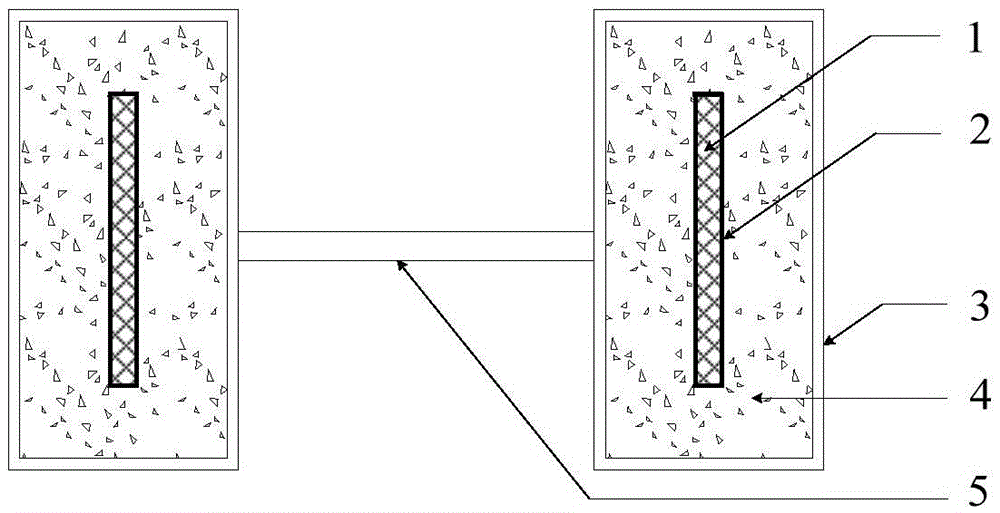

[0016] Attached below Figure 1~6 , to describe in detail the specific embodiments of the present invention.

[0017] Such as Figure 1~3 As shown, a split-type double-rectangular section buckling-resistant support member includes the following components:

[0018] 1——Inline core components, two in total;

[0019] 2——No bonding material;

[0020] 3—constrained rectangular steel pipes, two in total;

[0021] 4 - Concrete;

[0022] 5——steel web;

[0023] 6—end ribs;

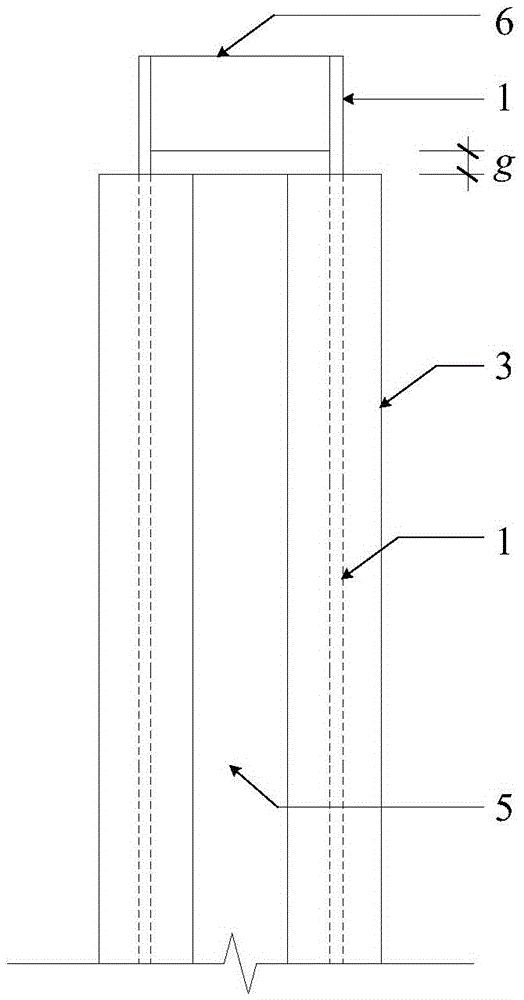

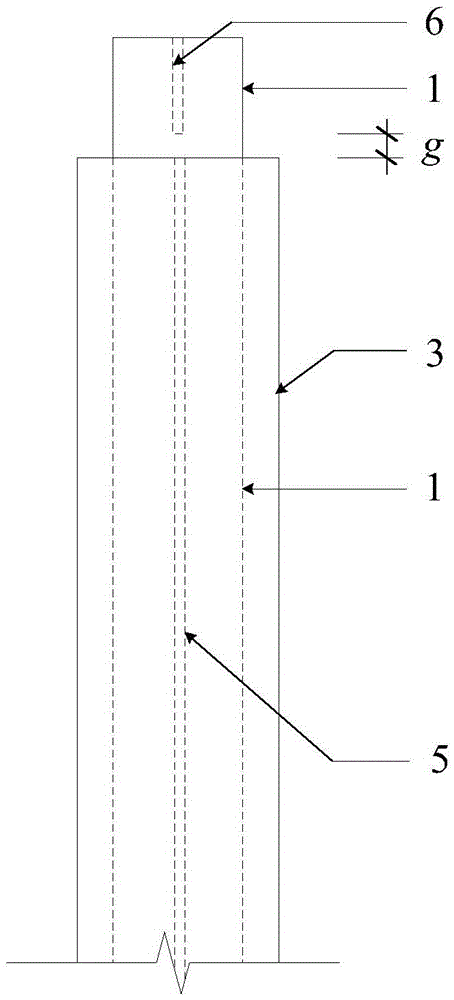

[0024] Such as figure 1 , 4 , 5, the separated double-rectangular tube-section buckling-resistant bracing member is composed of two buckling-resistant bracing limbs connected by steel webs 5; Components are composed of inline core components 1, unbonded materials 2, constrained rectangular steel pipes 3, and inner poured concrete 4;

[0025] Such as Figure 4 , 5 As shown, there are two constrained rectangular steel pipes 3 with the same size, which are composed of cold-formed thin-walled steel directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com