Nondestructive detection device for high-energy X-ray of nuclear fuel assembly

A nuclear fuel assembly, non-destructive testing technology, applied in the direction of material analysis using radiation, can solve problems such as failure to work normally, inability to obtain three-dimensional imaging, equipment or component damage, etc., to achieve the effect of optimizing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0053] The high-energy X-ray non-destructive detection device for nuclear fuel assemblies of the present invention can perform non-destructive detection of nuclear fuel assemblies of nuclear reactors, protect the normal operation of equipment and modules in the detection environment, realize effective shielding in high-level environments, and remove high-energy in special detection environments. The radioactive background is processed by a three-dimensional reconstruction algorithm to form a three-dimensional image of the nuclear fuel assembly. On this basis, specific defects and details of the nuclear fuel assembly can be observed.

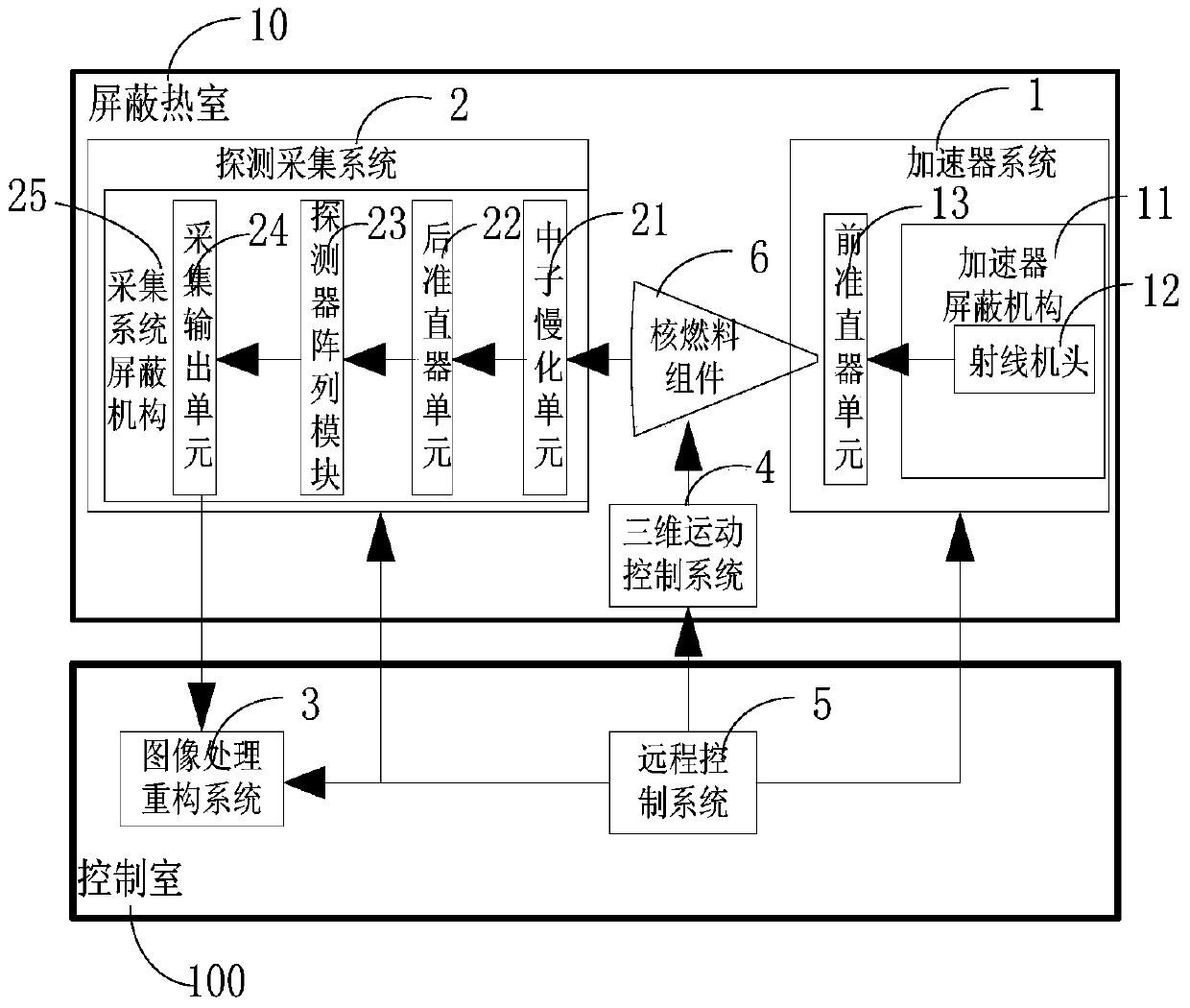

[0054] See figure 1 As shown, it is a functional block diagram of a high-energy X-ray non-destructive testing device for nuclear fuel assemblies of the present invention. The non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com