A high-power array LED chip surface heat dissipation structure and manufacturing method

A technology of LED chip and heat dissipation structure, which is applied to semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the application limitation of nitride array LED chips, the heat of light-emitting units cannot be dissipated well, and the heat dissipation of LED chips can be solved. Ineffective and other problems, to achieve high-efficiency high-power LED lighting, saving experiment or production costs, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

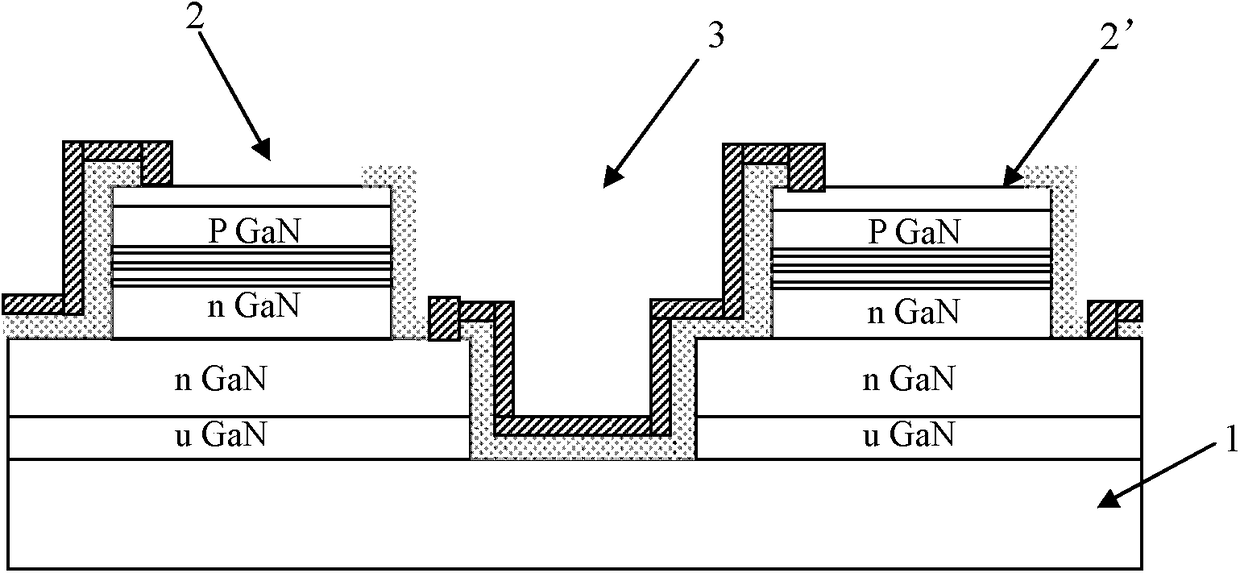

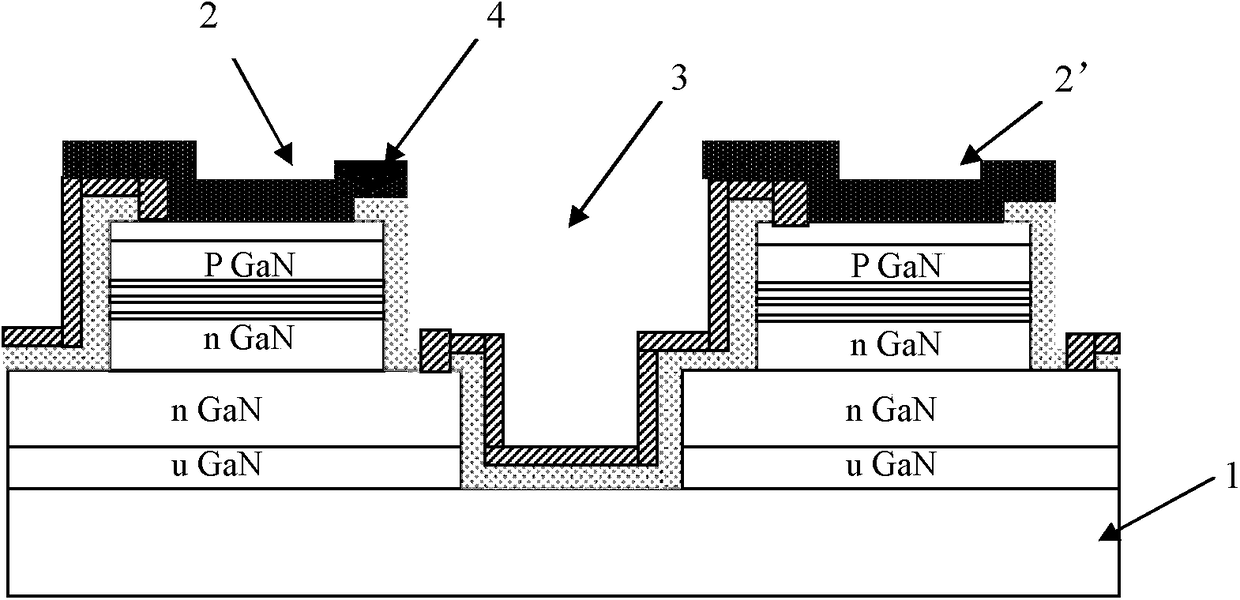

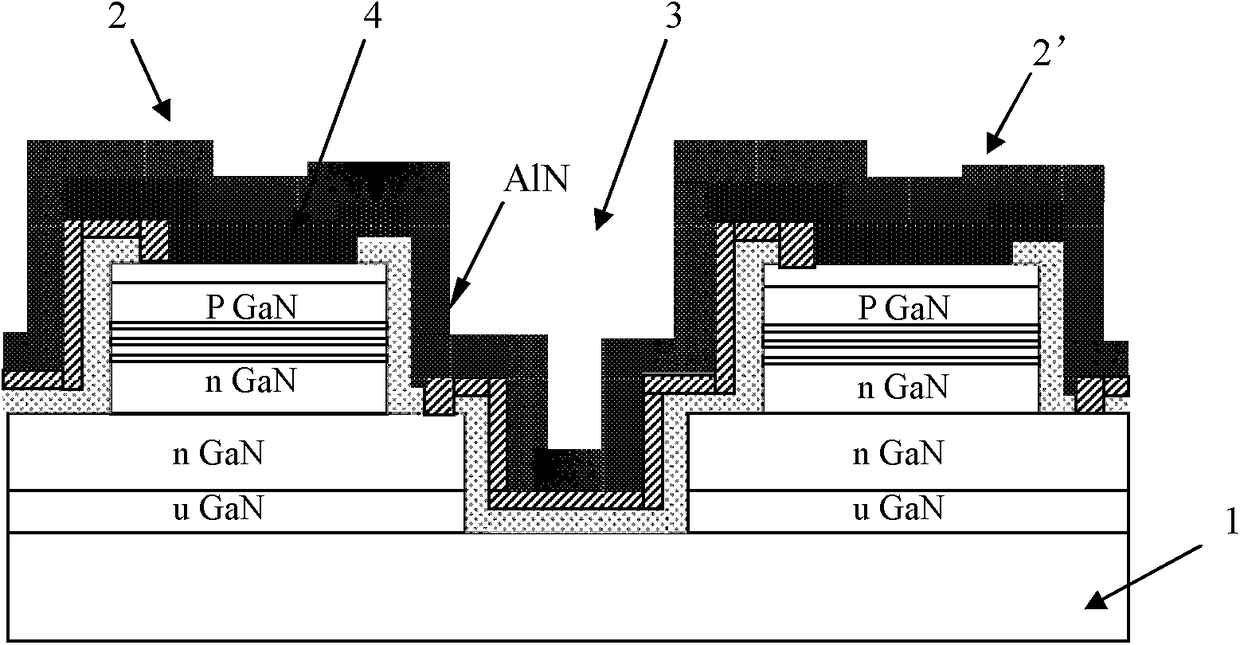

[0055] see Figure 13 , the cross-sectional view of the surface heat dissipation structure of the high-power array LED chip of the present invention, the substrate 1 is the most common sapphire substrate, the distance between adjacent light-emitting units 2 and 2' is 10-30 microns, and the distance between the light-emitting units 2 and 2' is bridged The metal is connected. Although the isolation groove 3 between the light-emitting units 2 and 2' is filled with a silicon dioxide layer and a titanium / aluminum / titanium / gold bridging layer, the groove still has a certain depth. Easily hides air bubbles. When the light-emitting unit emits light, it will generate a lot of heat, and this part of the heat will spread in all directions. The thermal conductivity of sapphire is poor. If this part of the heat is not properly treated, the temperature of the light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com