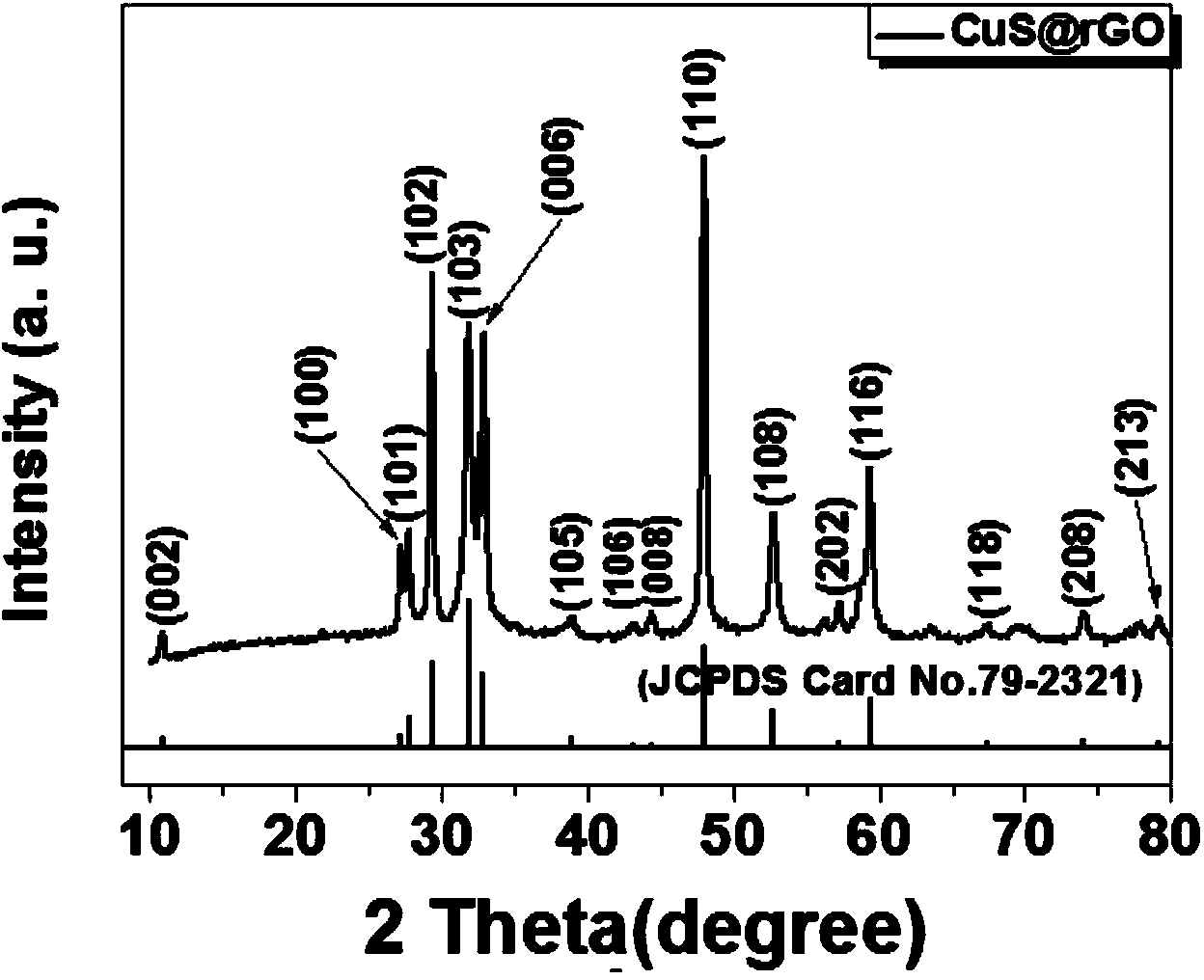

Anode material CuS@rGO of lithium ion battery and preparation method of anode material CuS@rGO

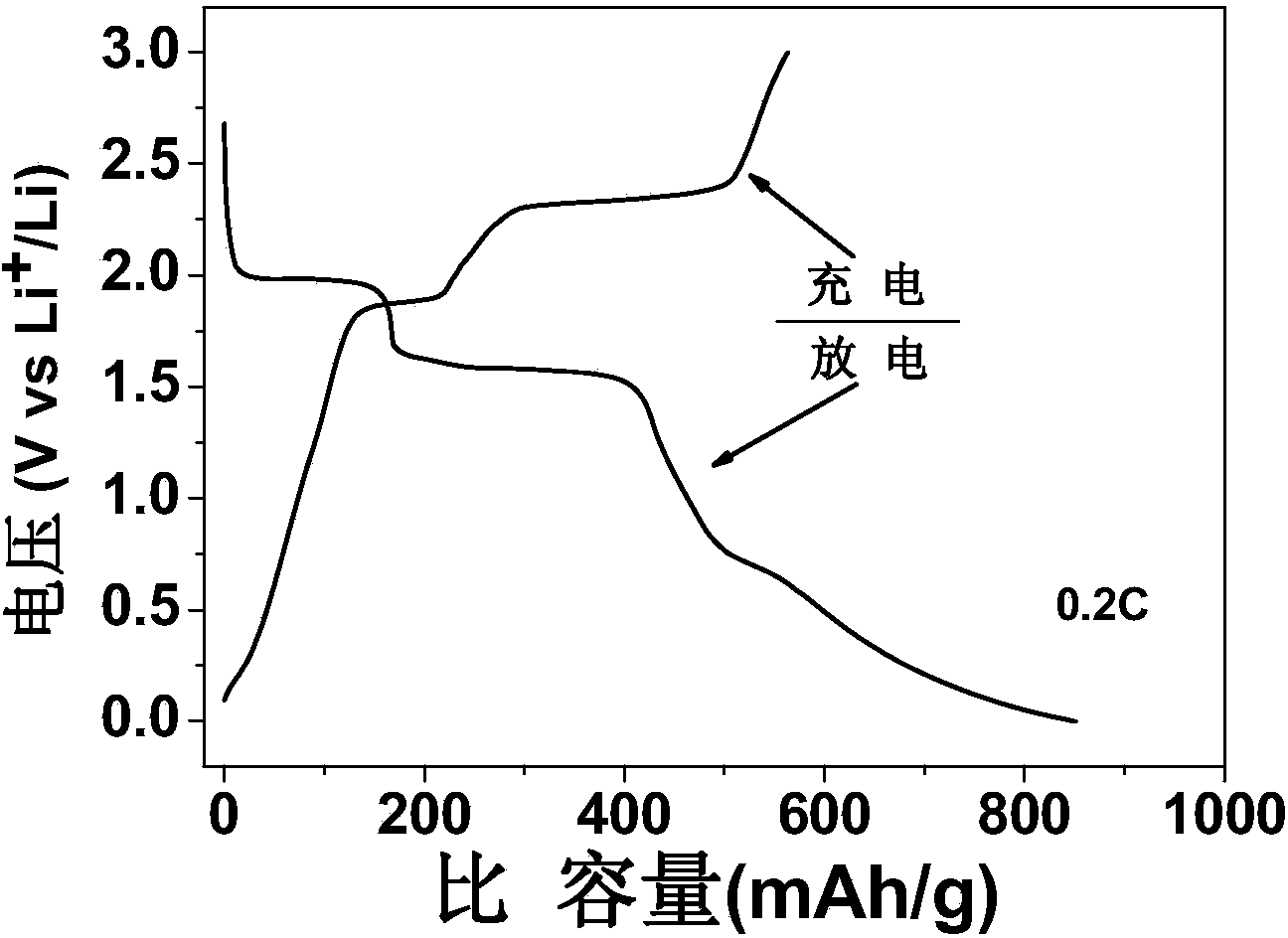

A lithium-ion battery and anode material technology, which is applied in the field of optoelectronic device preparation, can solve the problems of low coulombic efficiency and high charge-discharge platform of pure graphene materials in the first cycle, and achieve enhanced cycle stability, high first-time discharge capacity, and reduced internal stress. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

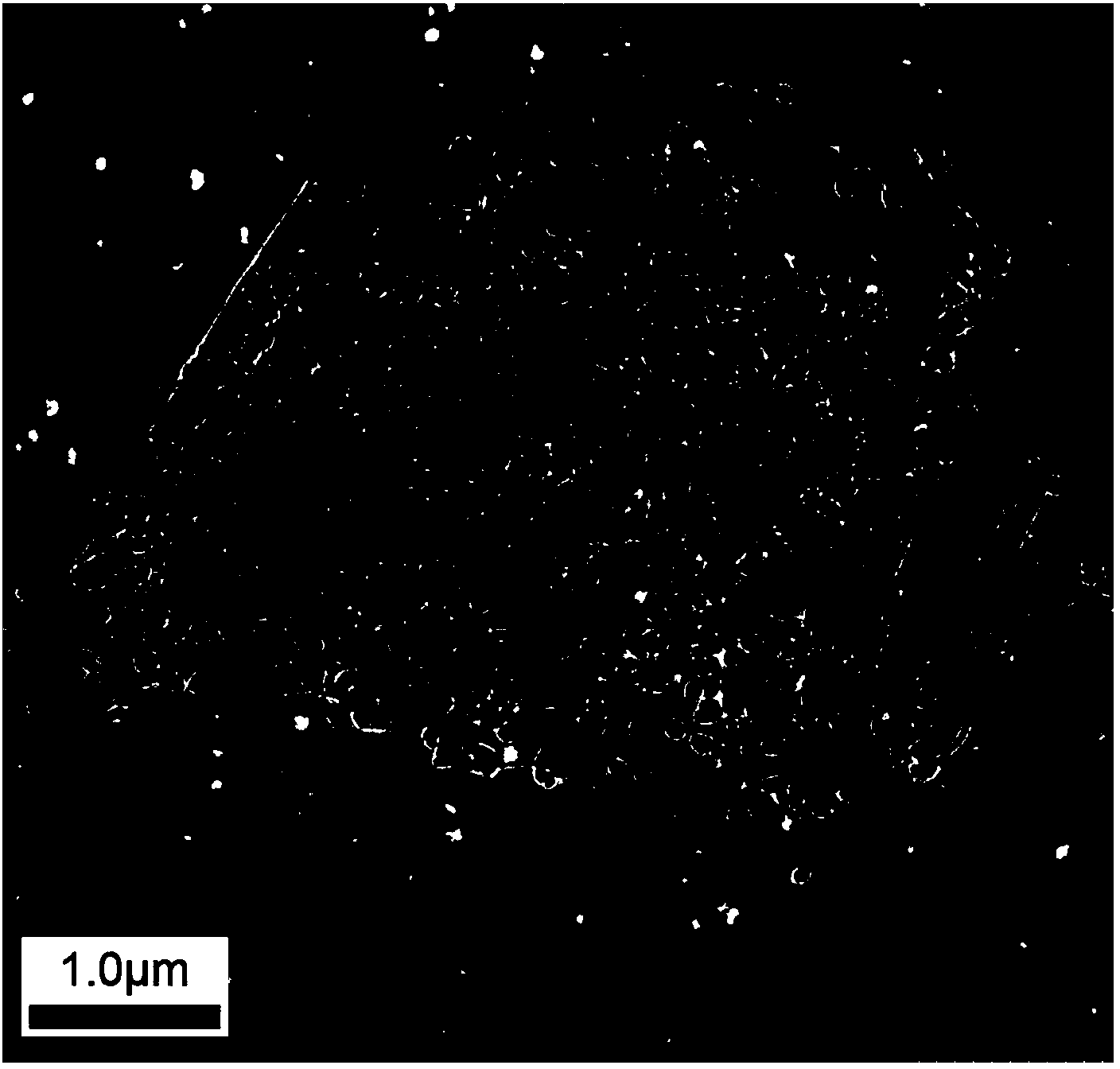

Image

Examples

Embodiment 1

[0024] a. Graphite oxide (GO) was prepared by the modified Hummer's method.

[0025] b. Disperse 40 mg of GO into 40 ml of deionized water, stir for 3 hours, sonicate for 20 minutes, then slowly add 2 mmol (0.5 g) of CuSO 4 ·5H 2 O, stirred for 2 hours; then slowly added 6 mmol (1.844 g) of reduced glutathione (GSH, C 10 h 17 N 3 o 6 S), stirred for another 30 minutes, put into a 50 ml stainless steel reaction kettle, sealed and put into a blast drying oven, heated to 200° C. for 10 hours, and naturally cooled to room temperature.

[0026] c. Filter, wash with deionized water and absolute ethanol three times respectively, and dry at 80° C. for 10 hours to obtain CuSGO.

[0027] d. Re-disperse in 40 ml of deionized water, stir for 30 minutes, add 10 mg of NaBH 4 , stirred for 10 minutes, hydrothermal reaction again, heated to 120 ° C for 4 hours, and naturally cooled to room temperature.

[0028] e. Filter, wash with deionized water and absolute ethanol three times respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com