Agricultural covering material

A covering and agricultural technology, applied in agriculture, agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of excessive rainwater immersion, light weight, poor transparency, pest intrusion, etc., and achieve high light transmittance and thermal insulation. Excellent, crop protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0086] Using a propylene homopolymer (PP-1) with an MFR of 20g / 10min, melt spinning at 230°C, the resulting fibers were deposited on the collection surface, and the fibers were obtained with a diameter of 40μm and a mesh weight of 9g / m 2 The spunbonded nonwoven layer (B-1).

[0087] Then, the propylene homopolymer (PP-2) with an MFR of 400 g / 10 minutes was melted at 280°C with an extruder, and the resulting melt was discharged from the spinneret while blowing 280°C The melt-blown method of heating air, depositing fibers with a fiber diameter of 3 μm on the above-mentioned spunbonded nonwoven fabric (B-1) to form a basis weight of 0.5 g / m 2 The melt-blown nonwoven fabric (A-1) was laminated on it with the same spunbonded nonwoven fabric (B-2) as the above-mentioned spunbonded nonwoven fabric (B-1), with a marking area ratio of 18 % hot embossed rolls to integrate the three layers to obtain an agricultural covering material in which a spunbond nonwoven fabric (hereinafter refer...

Embodiment 2)

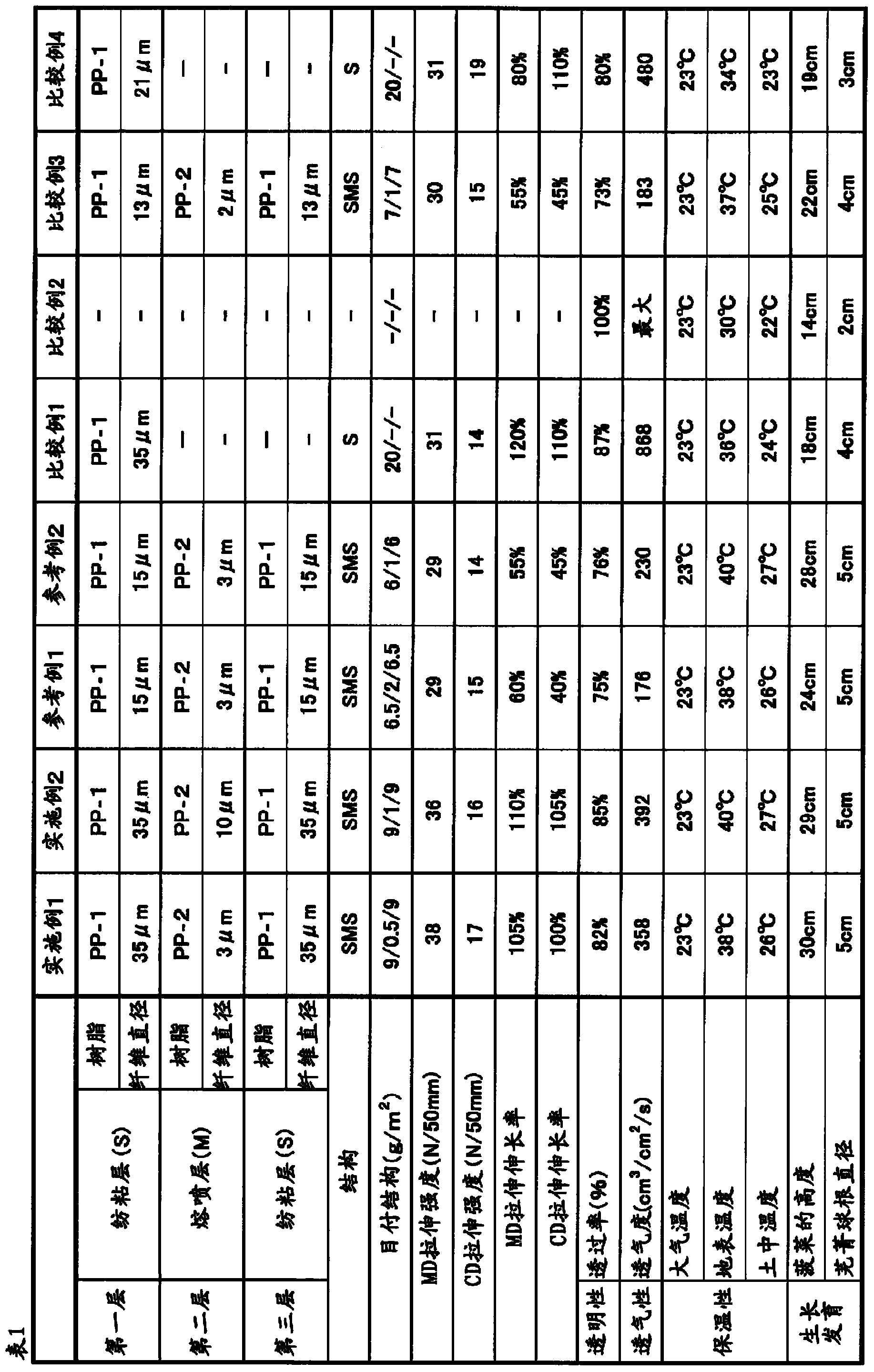

[0090] Except that the agricultural covering material used in Example 1 was replaced by spunbonded nonwoven fabrics and meltblown nonwoven fabrics having the fiber diameters and mesh weights described in Table 1, the agricultural covering materials were obtained in the same manner as in Example 1. material.

[0091] The obtained covering material for agriculture was evaluated by the method described above. The results are shown in Table 1.

[0092] (Reference example 1, 2)

[0093] Except that the agricultural covering material used in Example 1 was replaced by spunbonded nonwoven fabrics and meltblown nonwoven fabrics having the fiber diameters and mesh weights described in Table 1, the agricultural covering materials were obtained in the same manner as in Example 1. material.

[0094] The obtained covering material for agriculture was evaluated by the method described above. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com