Large-phase-ratio extraction device for organic liquid film on bubble surface

An extraction device and organic technology, applied in the field of solvent extraction and separation, can solve problems such as difficult clarification, phase separation, emulsification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

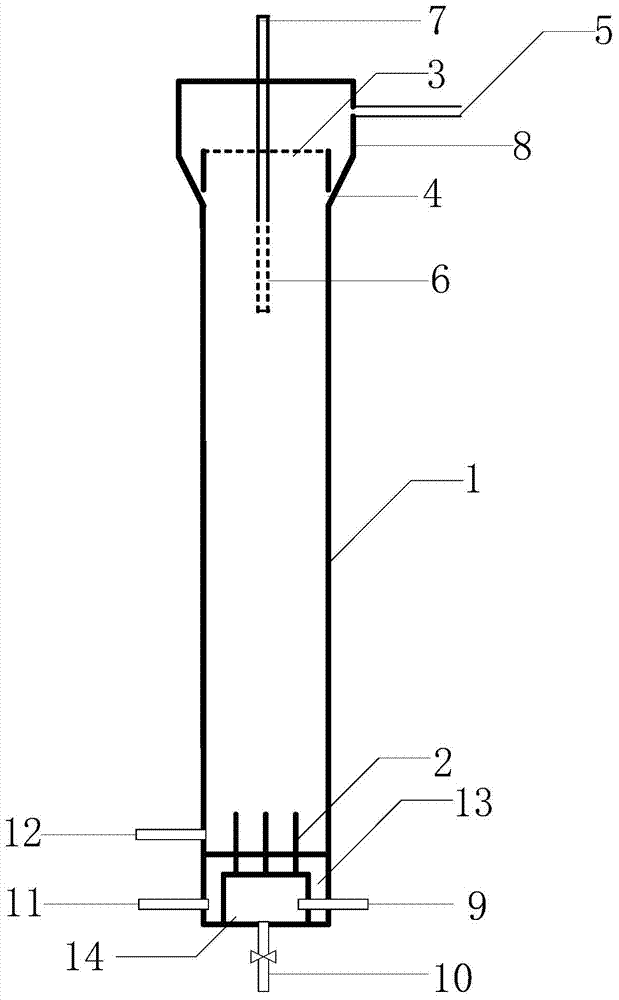

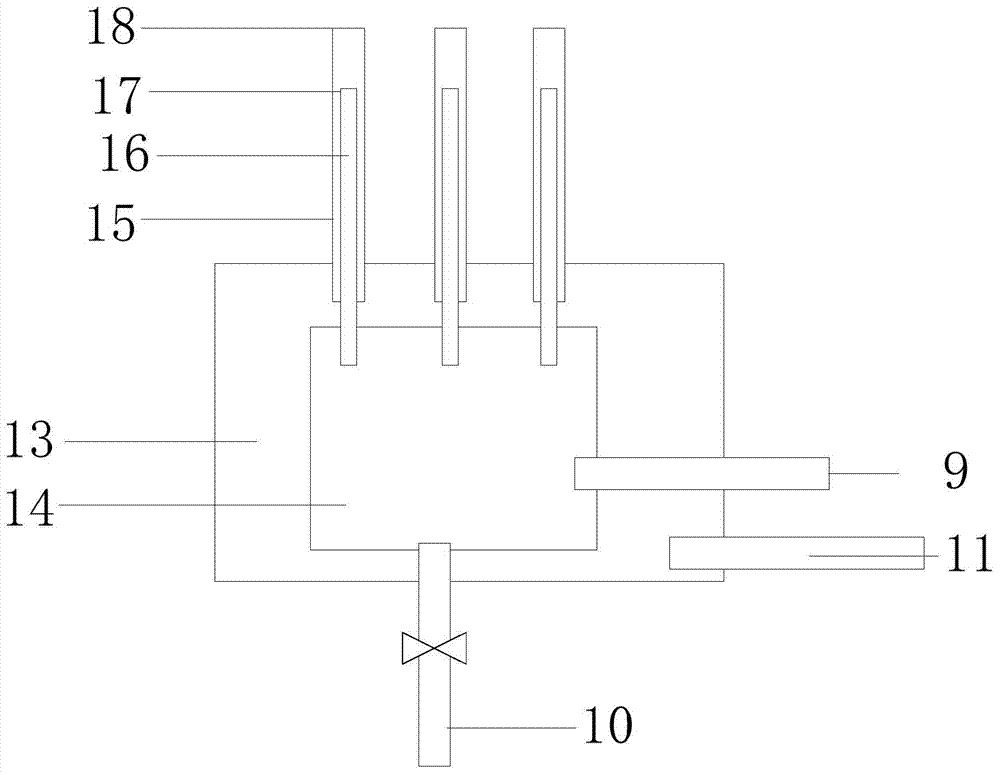

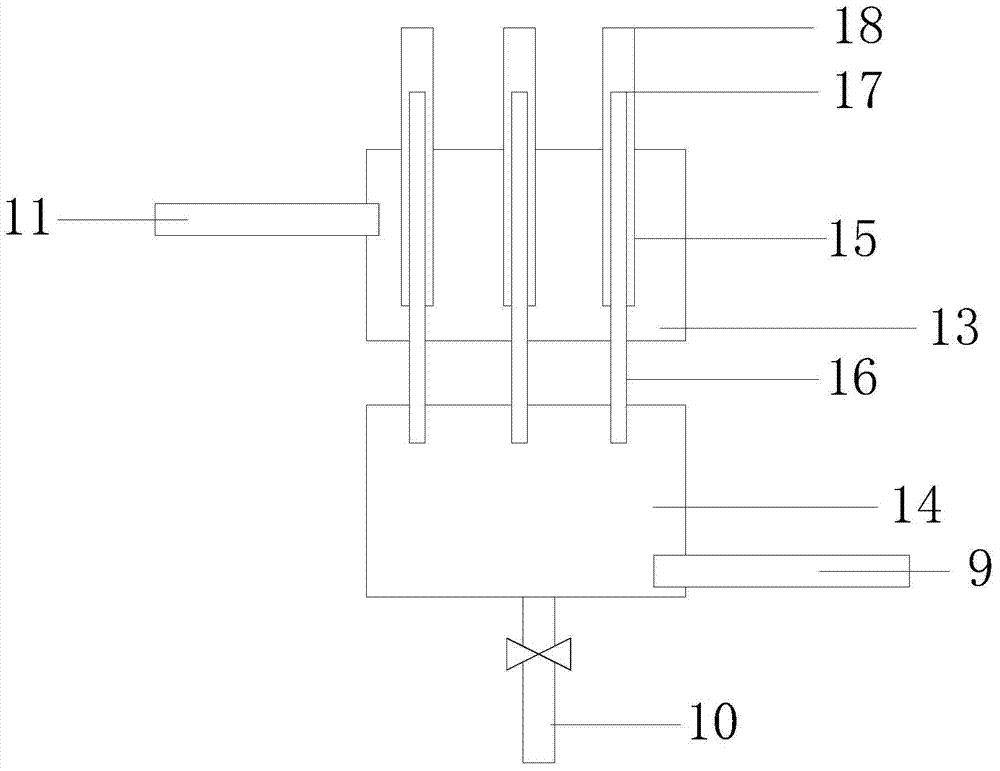

[0059] according to figure 1 , to manufacture a set of this device. Two glass tube columns with an outer diameter of 200mm and a length of 1500mm are used to connect vertically, as a column body, with a total length of 3000mm, and the connection between the two glass tube columns is connected by a flange; the lower end of the column body is connected to the oil phase bubble distributor. Adopt flange connection. The oil phase distribution head is made of polytetrafluoroethylene. The gas phase inlet, the oil phase inlet, the water phase outlet, and the water phase exhaust port are made of DN20 UPVC pipes, and quick-opening valves are installed on them. The enlarged section above the cylinder adopts a stainless steel cylinder with an inner diameter of 400mm, which is 600mm high, and the inner diameter of the lower conical neck is 200mm, and is connected with a glass tube with an outer diameter of 200mm by a flange. An oil phase accumulator is set in the enlarged section above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com