Catalyst for selectively reducing hydrogen cyanide release in cigarette mainstream smoke based on nickel oxide and preparation method thereof

A cigarette mainstream smoke and selectivity technology, applied in the field of cigarette manufacturing, can solve the problems of restricting the application of activated carbon materials and having a great impact, and achieve the effects of reduced content, simple production process, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dry 10 grams of 40-80 mesh alumina carrier at 150 degrees Celsius for 12 hours, and mix with 25 milliliters of 5mol / L NH 4 The F aqueous solution was mixed, then dried at 100°C for 12 hours, and calcined at 500°C for 4 hours to obtain a pretreated alumina carrier for future use. Then, using an equal volume impregnation method, 0.167 grams of nickel chloride hexahydrate was formulated into a corresponding aqueous solution, and 1 gram of pretreated alumina carrier was added to the solution, and dried at 70 degrees Celsius for 48 hours to obtain a catalyst precursor . Finally, the catalyst precursor was calcined at 400 degrees Celsius for 4 hours under the protection of an air atmosphere to obtain a catalyst.

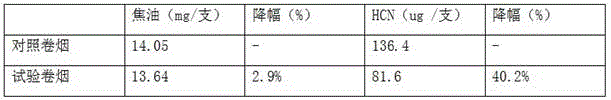

[0025] A section of filter column (15mm length) added with 50mg of catalyst is arranged on the filter tip close to the shredded tobacco section to make a composite filter tip and make a cigarette. The sample processing and smoking environment are in accordance wit...

Embodiment 2

[0029] Dry 10 grams of 40-80 mesh alumina carrier at 150 degrees Celsius for 12 hours, and mix with 25 milliliters of 5mol / L NH 4 The F aqueous solution was mixed, then dried at 100°C for 12 hours, and calcined at 500°C for 4 hours to obtain a pretreated alumina carrier for future use. Then, using the equal volume impregnation method, 0.032 grams of nickel chloride hexahydrate was prepared into a corresponding aqueous solution, and 1 gram of pretreated alumina carrier was added to the solution, and dried at 70 degrees Celsius for 48 hours to obtain a catalyst precursor . Finally, the catalyst precursor was calcined at 400 degrees Celsius for 4 hours under the protection of an air atmosphere to obtain a catalyst.

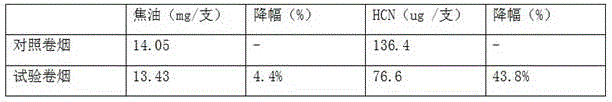

[0030] The hydrogen cyanide removal rate test method of catalyst is identical with embodiment 1, and this catalyst sees the following table 2 to the effect of selectively reducing hydrogen cyanide in cigarette mainstream smoke:

[0031] Table 2 Harm reduction eff...

Embodiment 3

[0034] Dry 10 grams of 40-80 mesh alumina carrier at 150 degrees Celsius for 12 hours, and mix with 25 milliliters of 5mol / L NH 4 The F aqueous solution was mixed, then dried at 100°C for 12 hours, and calcined at 500°C for 4 hours to obtain a pretreated alumina carrier for future use. Then, using the equal volume impregnation method, 0.003 grams of nickel chloride hexahydrate was formulated into a corresponding aqueous solution, and 1 gram of pretreated alumina carrier was added to the solution, and dried at 70 degrees Celsius for 48 hours to obtain a catalyst precursor . Finally, the catalyst precursor was calcined at 400 degrees Celsius for 4 hours under the protection of an air atmosphere to obtain a catalyst.

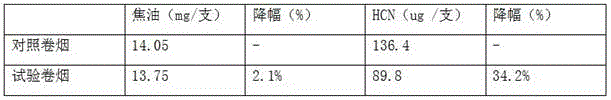

[0035] The hydrogen cyanide removal rate test method of catalyst is identical with embodiment 1, and this catalyst sees the following table 3 to the effect of selectively reducing hydrogen cyanide in cigarette mainstream smoke:

[0036] Table 3 Harm reduction e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com