Automatic alarm and protection device for tank car pneumatic conveying system

A pneumatic conveying system and automatic alarm technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., to save time and labor, improve communication conditions, and avoid adverse effects on sintering production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and specific embodiments:

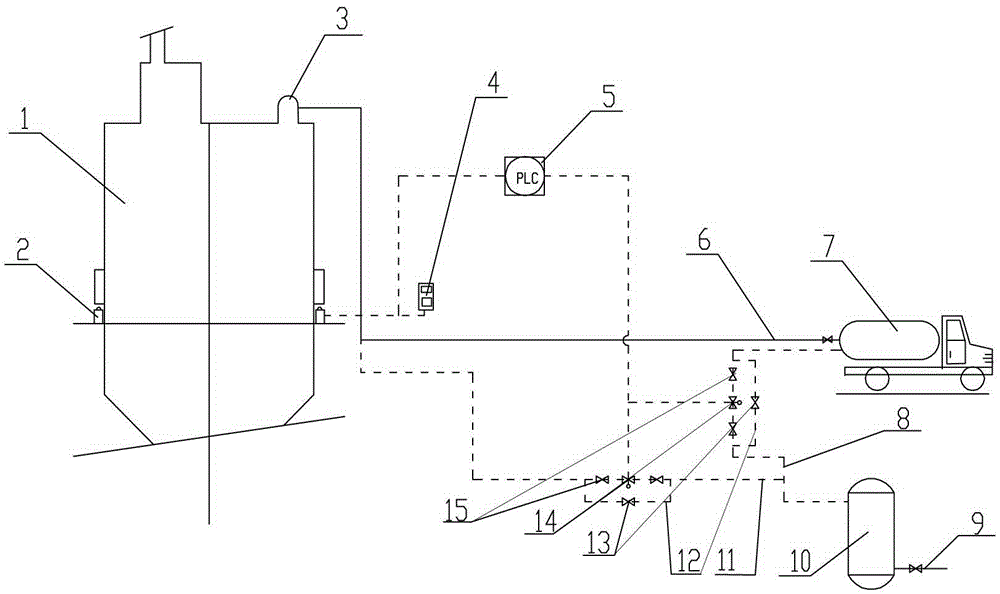

[0017] Such as figure 1 As shown, the automatic alarm and protection device of the tank car pneumatic conveying system of the present invention includes a flux-sealed mine bin 1, a mine weighing system arranged on the flux-sealed mine bin 1, and a remote PLC mine bin located in the central control room of the plant The control system 5, the tank car 7 connected to the inlet 3 of the flux-sealed ore bin 1 through the flux conveying pipe 6, and the compressed air supply system connected to the flux conveying pipe 6 and the tank car 7, are characterized by:

[0018] The said silo weighing system consists of a weighing level meter 2 set on the platform support of the flux-sealed ore silo 1 and one end connected to the weighing level meter 2 through a communication bus, and the other end is connected to the remote PLC mine silo The control system 5 is composed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com