Bottom spray-seeding substrate containing fermented sludge and preparation method thereof

A technology of sludge and bottom layer, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of undisclosed bottom spraying base material, lack of final outlet, etc., to prevent and control soil erosion, increase soil fertility, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

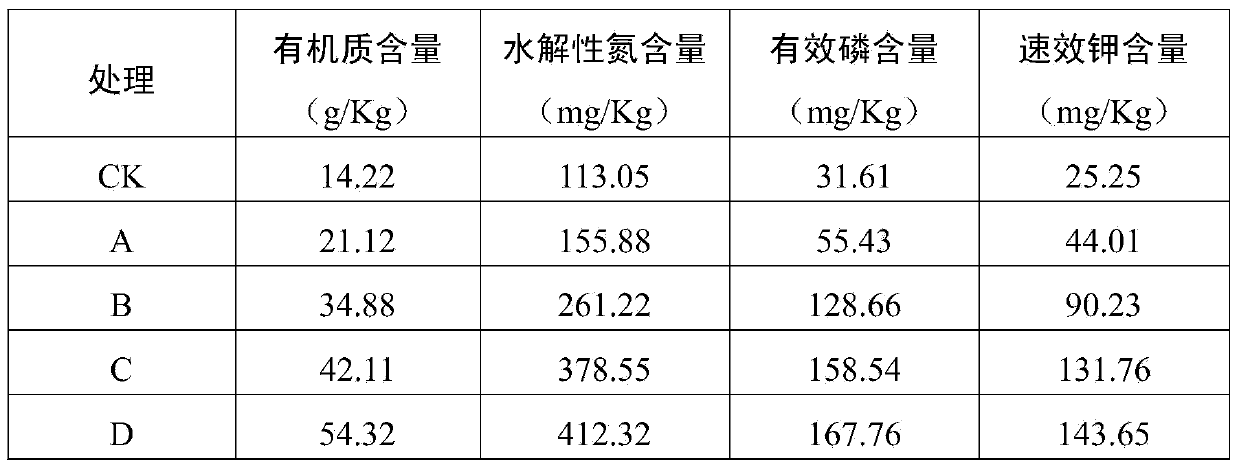

Examples

Embodiment 1

[0043] A method of preparing a method of spraying a base material, comprising:

[0044] (1) Remove stones, tree roots and other sundries in the loam;

[0045] (2) Sieve the loam with a sieve aperture of 1.5cm;

[0046] (3) The sieved loam is divided into 10 parts by volume of fermented sludge, 10 parts of organic matter (straw, peanut, rice, sawdust and wood shavings), and 80 parts of loam (in m 3 ) mixed evenly at room temperature (20°C), the application amount of soil water retaining agent (SAP), binder (PAM) and microbial inoculant is calculated based on the volume of the mixture of fermented sludge, loam and organic matter, according to soil water retention Agent 150g / m 3 , Adhesive 100g / m 3 And microbial agent 45g / m 3 After adding the soil water retaining agent, binder and microbial agent, stir again and mix evenly.

Embodiment 2

[0048] A method of preparing a method of spraying a base material, comprising:

[0049] (1) Remove stones, tree roots and other sundries in the loam;

[0050] (2) Sieve the loam with a sieve aperture of 1.5cm;

[0051] (3) The sieved loam is divided into 25 parts of fermented sludge, 10 parts of organic matter (straw, rice, sawdust and wood shavings), and 65 parts of loam (in m 3 ) mixed evenly at room temperature (22°C), the application amount of soil water retaining agent (SAP), binder (PAM) and microbial inoculant is calculated based on the volume of the mixture of fermented sludge, loam and organic matter, based on soil water retention Agent 150g / m 3 , Adhesive 100g / m 3 And microbial agent 45g / m 3 After adding the soil water retaining agent, binder and microbial agent, stir again and mix evenly.

Embodiment 3

[0053] A method of preparing a method of spraying a base material, comprising:

[0054] (1) Remove stones, tree roots and other sundries in the loam;

[0055] (2) Sieve the loam with a sieve aperture of 1.5cm;

[0056] (3) The sieved loam is divided into 30 parts of fermented sludge, 10 parts of organic matter (straw, peanut, rice and wood shavings), and 65 parts of loam (the units are all m 3 ) at room temperature (25°C) and mix evenly. The application amount of soil water retaining agent (SAP), binder (PAM) and microbial agent is calculated based on the volume of the mixture of fermented sludge, loam and organic matter, and is calculated according to soil water retention Agent 150g / m 3 , Adhesive 100g / m 3 And microbial agent 45g / m 3 After adding the soil water retaining agent, binder and microbial agent, stir again and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com