Colored paint/ink cured on tyre by using ultraviolet light and preparation method thereof

A technology of color coating and ultraviolet light, which is applied in the direction of ink, application, coating, etc., can solve the problems of low curing efficiency and VOC emission, and achieve the effect of high output, excellent performance, and simple operation of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Put 6 parts of cyclohexane, 2 parts of heptane, and 0.5 parts of styrene-butadiene rubber in a closed stirrer in parts by mass, stir for 1 hour at 65°C until completely dissolved, and cool to room temperature.

[0023] 2. Transfer the above solution to a dispersing mixer, add 5 parts of butyl acrylate, 3 parts of isodecyl acrylate, 0.8 parts of acrylic resin, and 0.01 part of polyether-modified polydimethylsiloxane, and stir for 30 minutes .

[0024] 3. Add 4 parts of color paste, 0.03 parts of a mixture of 52% polyacrylate and 48% alkylbenzene, and 0.22 parts of α-hydroxyalkyl phenone photoinitiator into the above-mentioned dispersing mixer, stir for 10 minutes, and discharge Instantly.

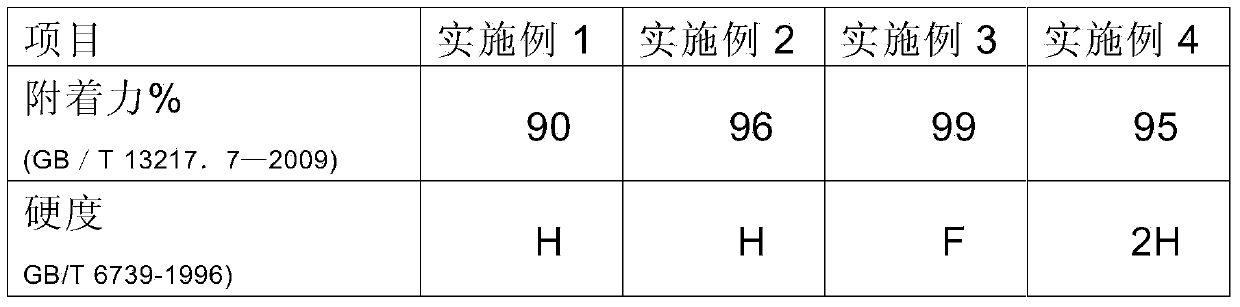

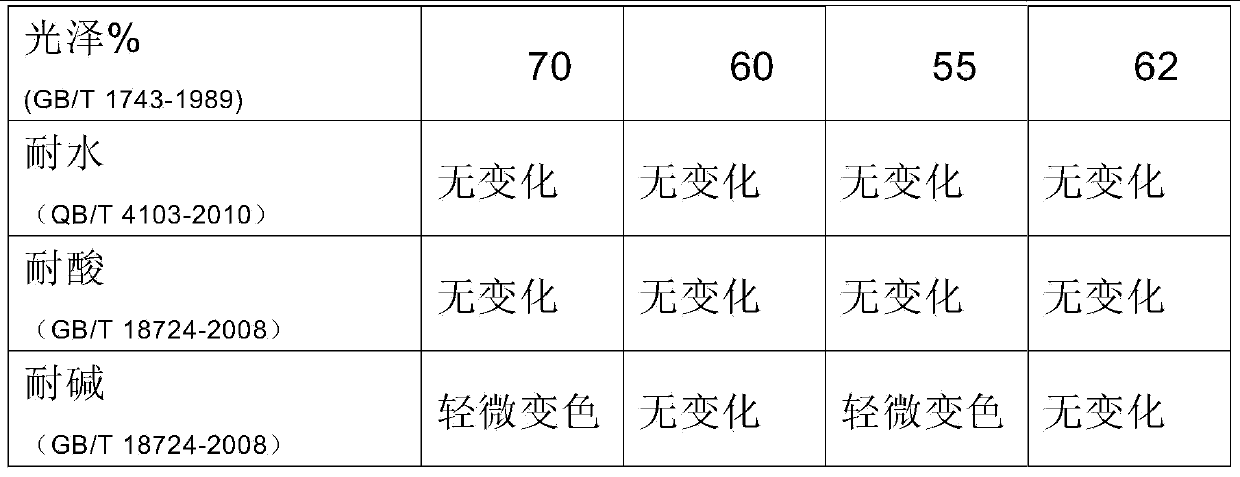

[0025] 4. Brush the above ink on the side of the clean tire, and cure it with UV radiation to form a coating film. The performance of the coating film was tested according to the national standard, as shown in Table 1.

Embodiment 2

[0027] 1. Put 12 parts of 200# gasoline solvent in parts by mass, 4 parts of cyclohexane, and 3 parts of butadiene rubber in a closed stirrer, stir for 2 hours at 70°C until completely dissolved, and cool to room temperature .

[0028] 2. Transfer the above solution to a dispersing mixer, add 18 parts of butyl methacrylate, 2 parts of styrene resin, and 0.12 parts of polyether-modified polydimethylsiloxane, and stir for 45 minutes.

[0029] 3. Add 8 parts of color paste, 0.1 part of a mixture of 52% polyacrylate and 48% alkylbenzene, and 1 part of α-aminoalkylphenone photoinitiator into the above-mentioned dispersing mixer, stir for 30 minutes, and discharge Instantly.

[0030] 4. Brush the above ink on the side of the clean tire, and cure it with UV radiation to form a coating film. The performance of the coating film was tested according to the national standard, as shown in Table 1.

Embodiment 3

[0032] 1. Put 10 parts by mass of ethyl acetate and 1 part of natural rubber in a closed stirrer, stir for 1.5 hours at 60°C until completely dissolved, and cool to room temperature.

[0033] 2. Transfer the above solution to a dispersing mixer, add 5 parts of isodecyl acrylate, 6 parts of cyclohexyl methacrylate, 2 parts of acrylic resin, 0.05 part of polyether-modified polydimethylsiloxane, Stir for 10 minutes.

[0034] 3. Add 6 parts of color paste, 0.08 part of a mixture of 52% polyacrylate and 48% alkylbenzene, and 0.5 part of α-aminoalkylphenone photoinitiator into the above-mentioned dispersing mixer, stir for 15 minutes, and discharge Instantly.

[0035] 4. Brush the above ink on the side of the clean tire, and cure it with UV radiation to form a coating film. The performance of the coating film was tested according to the national standard, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com