High-grade full-synthetic steam turbine oil and preparation method thereof

A fully synthetic, engine oil technology, applied in the field of lubricating oil, can solve problems such as poor low-temperature lubrication effect, high energy consumption in the preparation process, and poor corrosion resistance, and achieve low production costs, reduced energy consumption, and short production cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

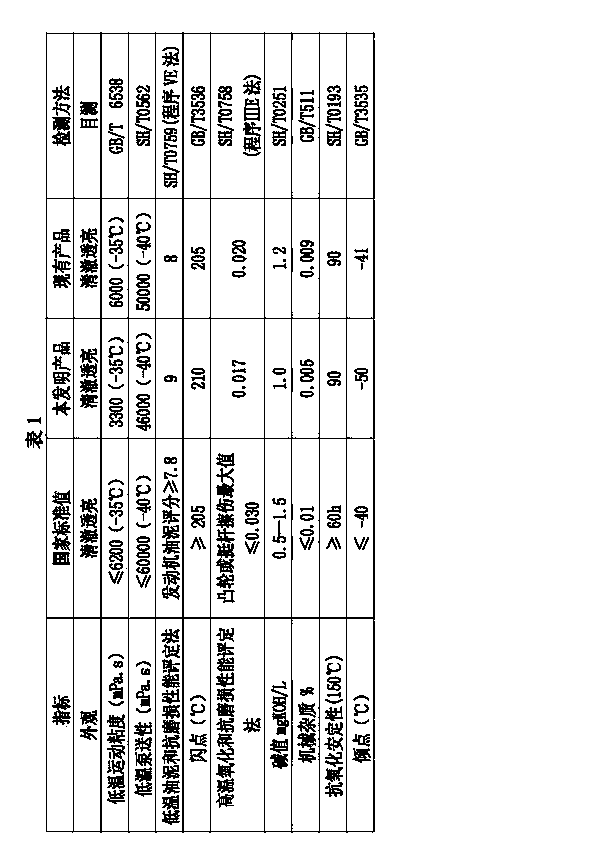

Image

Examples

Embodiment 1

[0020] Embodiment 1, the high-grade fully synthetic engine oil raw materials include 55 to 70 parts of poly-olefins, 20 to 25 parts of alkylnaphthalene synthetic oils, 10 to 15 parts of perfluorocarbon synthetic oils, and compounded 7 to 10 parts of additives, 0.5 to 1 part of naphthenic hydrochloric acid, 0.5 to 1 part of polyammonium salt additive and 0.5 to 1 part of organic crystal cosolvent. Naphthenates can reduce engine valve melting. Polyammonium salt additives can effectively solve the cleaning problem inside the engine and reduce carbon deposits. The compound additives have anti-wear, viscosity-increasing, anti-oxidation, and anti-corrosion properties. Antifoam and other multifunctional additives.

Embodiment 2

[0021] Embodiment 2, the high-grade fully synthetic engine oil raw material comprises 55 parts or 70 parts of poly-olefins, 20 parts or 25 parts of alkylnaphthalene synthetic oils, 10 parts or 15 parts of perfluorocarbon synthetic oils, compound 7 or 10 parts of additives, 0.5 or 1 part of naphthenic hydrochloric acid, 0.5 or 1 part of polyammonium salt additive and 0.5 or 1 part of organic crystal cosolvent.

Embodiment 3

[0022] Embodiment 3, as the optimization of above-mentioned embodiment, raw material comprises poly-alkene 58.8 parts, alkylnaphthalene synthetic oil 20 parts, perfluorocarbon synthetic oil 10.8 parts, composite additive 8.8 parts, naphthenic hydrochloric acid 0.75 parts by weight parts by weight. part, 0.75 part of polyammonium salt additive and 0.5 part of organic crystal co-solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com