Construction method of large multifunctional over-water construction platform

The technology of a construction platform and a construction method is applied in the construction field of a large-scale multi-functional water construction platform, which can solve the problems of cumbersome construction methods, high construction costs, and long periods for fixed platforms, so as to improve construction quality, reduce construction costs, save The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

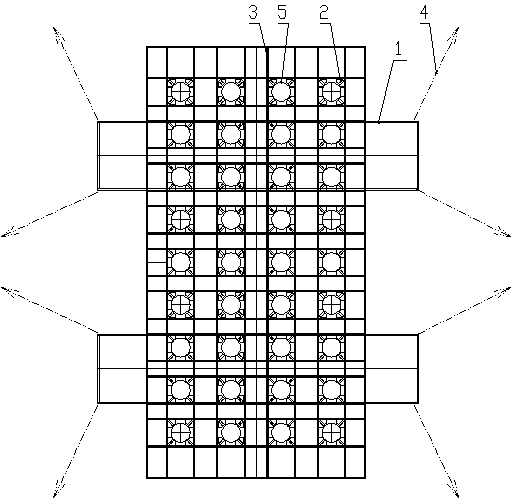

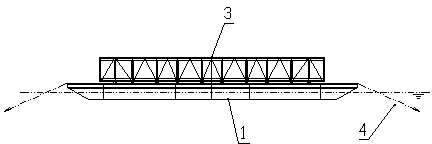

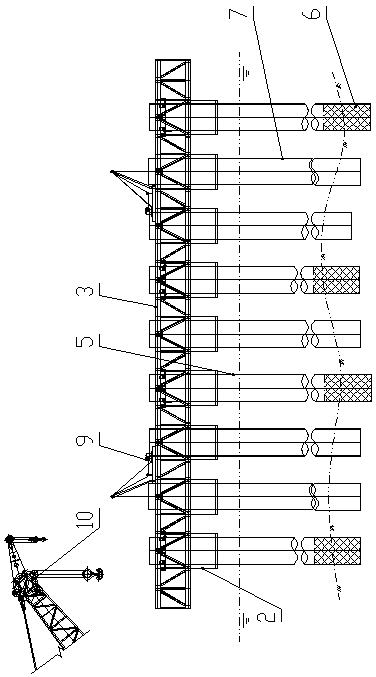

[0037] Such as Figure 1-Figure 8 Shown, the construction method of large-scale multifunctional water construction platform of the present invention, comprises the following steps:

[0038] (1) At least two floating bodies 1 are set on the water in advance, and the floating bodies 1 are anchored and positioned by anchor ropes;

[0039](2) Use a floating crane or crane to hoist the processed component units on the floating body 1, assemble the component units on the floating body 1, and install the guide device 2 during the assembly process, and connect the component units through bolts Or welded and assembled into a floating platform 3;

[0040] (3) Release the anchoring of the floating body 1, drag the floating body 1 and the platform 3 to the preset bridge pier by the tugboat, and then pull the anchor rope 4 to accurately position the floating body 1;

[0041] (4) At a suitable position on the side of the floating body 1, use floating cranes and piling equipment to pass th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com