Supercritical Carbon Dioxide Abrasive Jet Perforation Simulation Experiment System

A technology of carbon dioxide and abrasive jet, which is applied in the direction of mining fluid, drilling with liquid/gas jet, wellbore/well components, etc., to achieve the effect of improving experimental work efficiency and safety, enhancing investigation ability, and strong pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

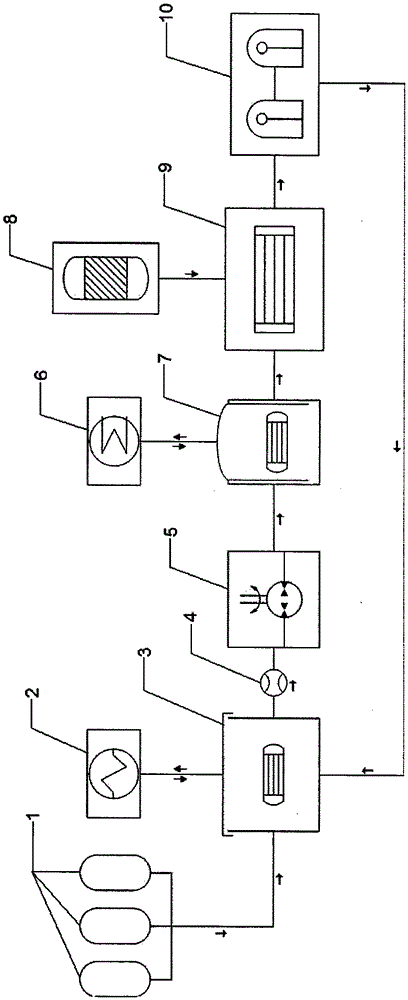

[0025] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0026] Such as figure 1 As shown, there is liquid carbon dioxide stored in the carbon dioxide gas cylinder 1, which is the carbon dioxide source of the whole experimental system, and the carbon dioxide flows into the constant temperature water bath cold box 3 under the self-pressure (above 4.5MPa) in the gas cylinder 1; The circulating water in the cold box 2 cools down (0-3°C), and then cools the carbon dioxide in the box; the liquid carbon dioxide enters the booster pump 5 through the flow meter 4, and the pressurized liquid high-pressure carbon dioxide is pumped into the constant temperature water bath heating box 7 , the heating device 6 heats the circulating water in the constant temperature water bath heating box 7, and the temperature of the constant temperature water bath heating box 7 can be adjusted between 20-100°C with an accuracy of ±0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com