Gas-catalysis flameless infrared radiation heating dryer

A technology of gas catalysis and external radiation, applied in drying, drying machine, heating device and other directions, can solve the problems of electric leakage of circuit wires, short service life and high operating cost, achieve convenient and fast use, high safety standards, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

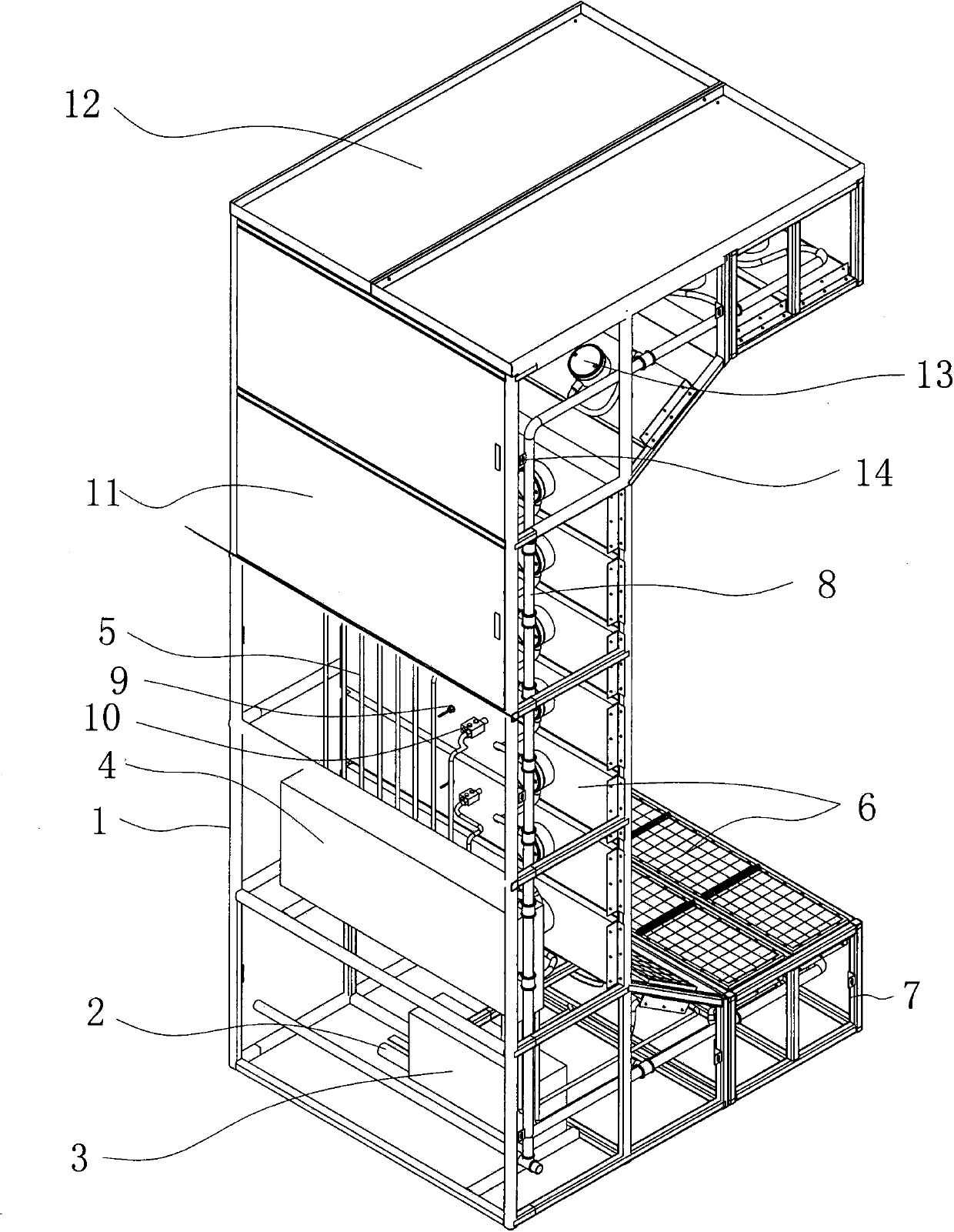

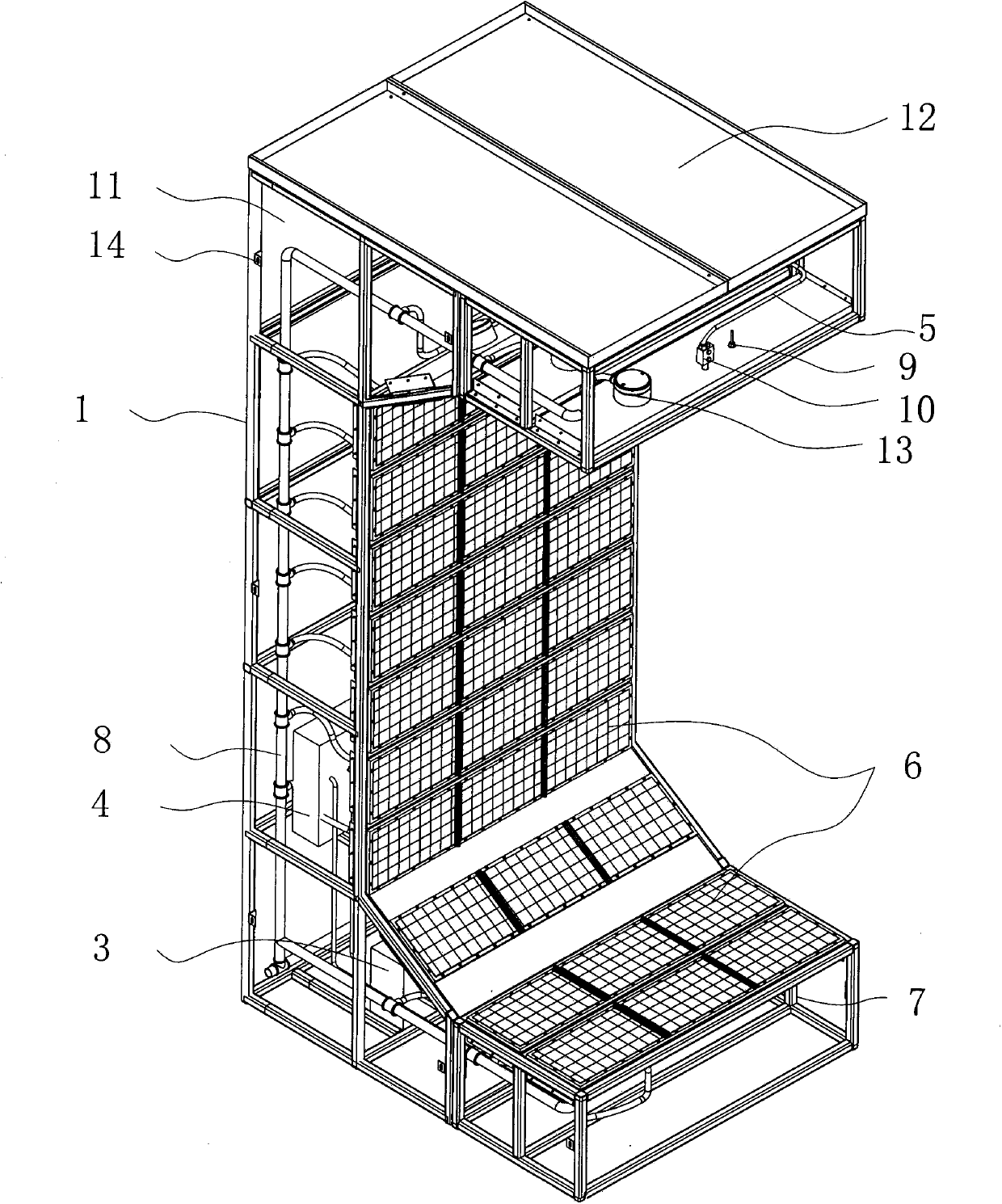

[0015] figure 1 with figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a side view structural schematic diagram of the present invention.

[0016] See figure 1 with figure 2 , a gas catalytic flameless infrared radiation heating dryer, comprising a fixed bracket assembly 1, a gas supply main pipe 2 arranged at the bottom of the fixed support assembly 1, a primary gas supply main pipe 2 connected to the The gas supply adjustment transmitter 3 and the secondary gas supply adjustment transmitter 4, the gas supply branch connected to the primary gas supply adjustment transmitter 3 and the secondary gas supply adjustment transmitter 4 5. The gas supply branch pipe 5 is vertically arranged, the fixed bracket assembly 1 is arranged in a C shape, and a gas catalytic flameless infrared radiation heater 6 is arranged inside the fixed bracket assembly 1, and the The gas catalyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com