Automatic wiring method and automatic wiring system for solar cells

A solar cell, automatic wiring technology, applied in information technology support systems, electrical digital data processing, special data processing applications, etc., can solve the problems of low efficiency and high labor intensity, to improve efficiency, reduce labor intensity, and improve wiring efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

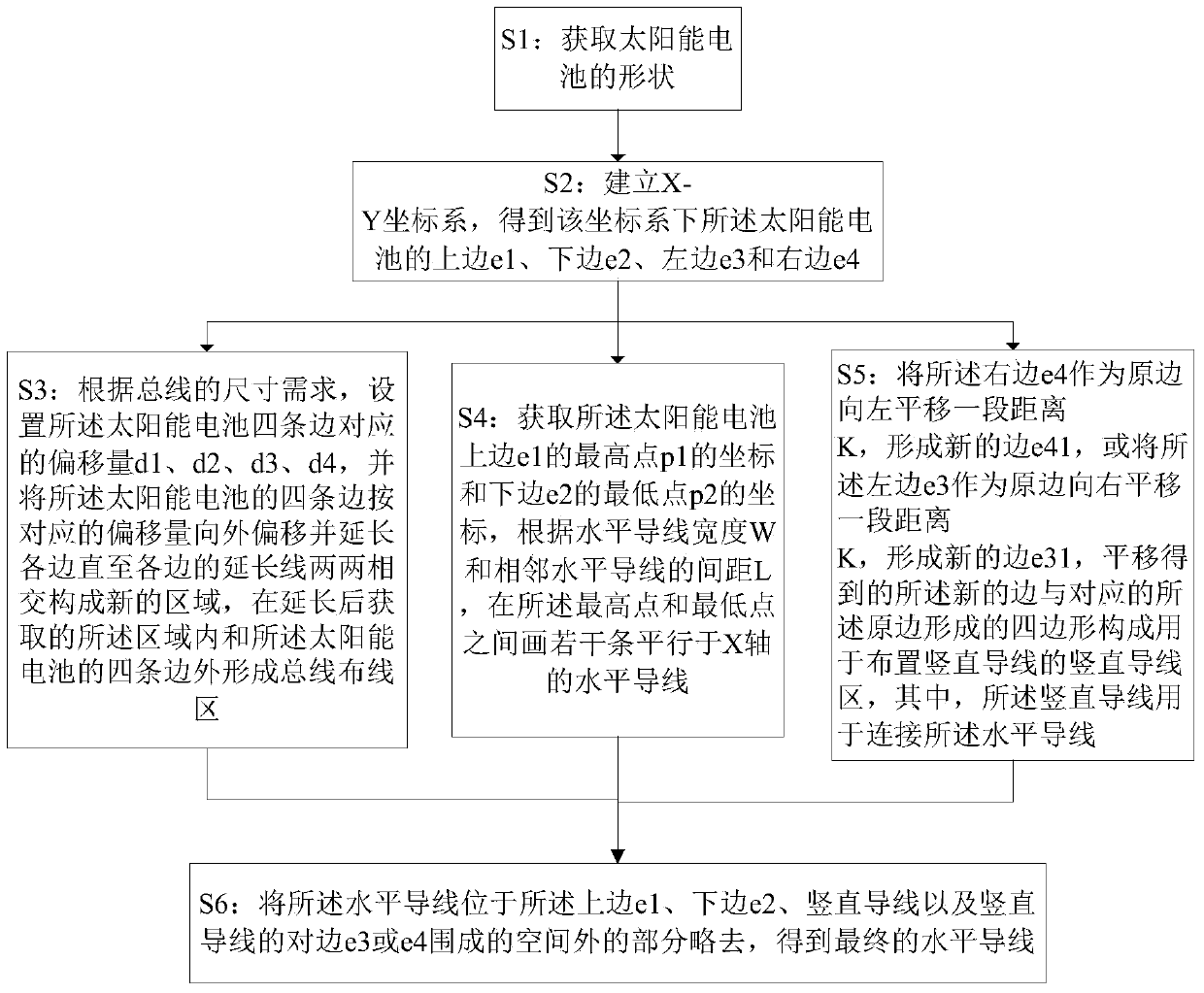

[0057] see figure 1 As shown, a method for automatic wiring of solar cells according to an embodiment of the present invention, a method for automatic wiring of solar cells, includes the following steps:

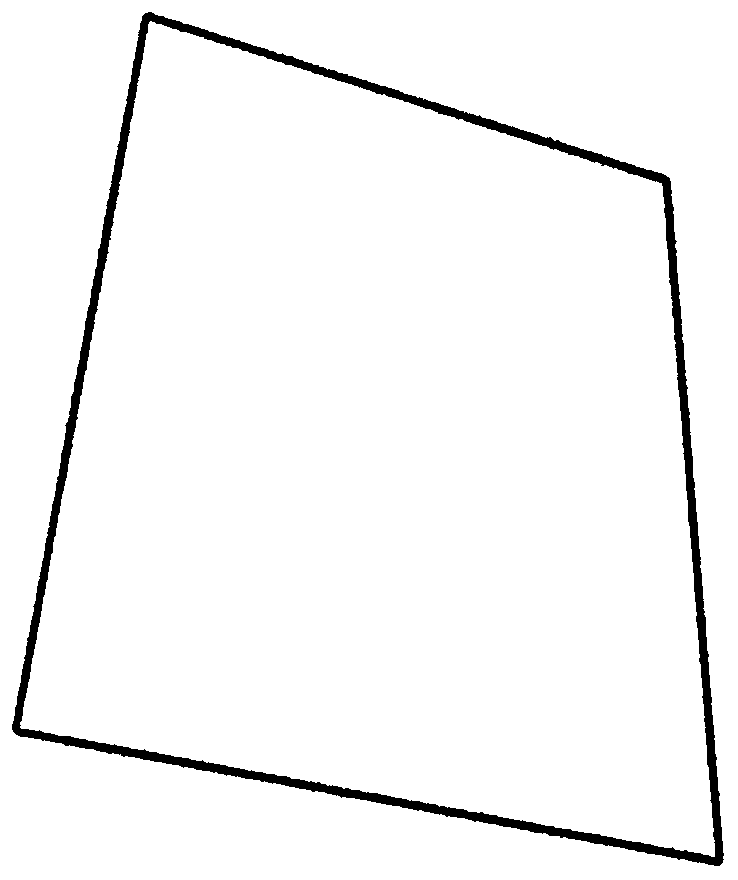

[0058] S1: Get the shape of the solar cell, for example image 3 As shown, obtain the shape of an irregular solar panel. Among them, there are many methods of acquisition, for example: providing four-point coordinates, side stakeout, or using 3dm, iges, dwg, etc. to directly import 3d graphic files.

[0059] S2: Establish an X-Y coordinate system, and obtain the upper side e1, lower side e2, left side e3 and right side e4 of the solar cell under the coordinate system, such as Figure 4 shown in .

[0060] S3: According to the size requirements of the bus, obtain the offsets d1, d2, d3, and d4 corresponding to the four sides of the solar cell. In this embodiment, the value of d1 is 4.9 mm, the value of d2 is 4.5 mm, and the value of d3 is is 8mm, and d4 takes the value of...

Embodiment 2

[0066] As an embodiment of the present invention, on the basis of the above-mentioned embodiment 1, between steps S5 and S6, the following steps are also included:

[0067] S51: Draw a circular arc structure at the junction between the horizontal wire and the bus wiring area, that is, the opposite side of the vertical wire (ie, the left e3 or the right e4).

[0068] According to the automatic wiring method of solar cells, drawing the arc structure of the connection between the bus wiring areas according to the above steps can reduce the hot spots caused by the high resistance value at the intersection of the wires.

Embodiment 3

[0070] As an embodiment of the present invention, on the basis of the above-mentioned embodiment 2, as Figure 5 As shown, in the step S51, the specific method of drawing the arc structure is: set the radius as R (in this embodiment, the value of R is 0.2mm), make a parallel line that is R at a distance from the horizontal wire, and make the distance inwards The opposite side of the vertical conductor is the parallel line of R, and the intersection point of the two parallel lines is the center of circle, and a circle with a radius of R is tangent to the opposite side of the vertical conductor and the horizontal conductor to obtain four points of tangency a, b, c, d, the arc between the tangent points a and b and the arc between the tangent points c and d are arc structures.

[0071] According to the automatic wiring method for solar cells, according to the above steps, the arc structure corresponding to the horizontal wire can be automatically obtained, avoiding the cumbersome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com