Potato pulp fermented feed and preparation method thereof

A fermented feed and potato dregs technology, applied in animal feed, animal feed, application, etc., can solve problems such as difficult storage, transportation, poor palatability, waste of resources, etc., to improve palatability and digestibility, improve nutritional value, The effect of reducing the amount of crude fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

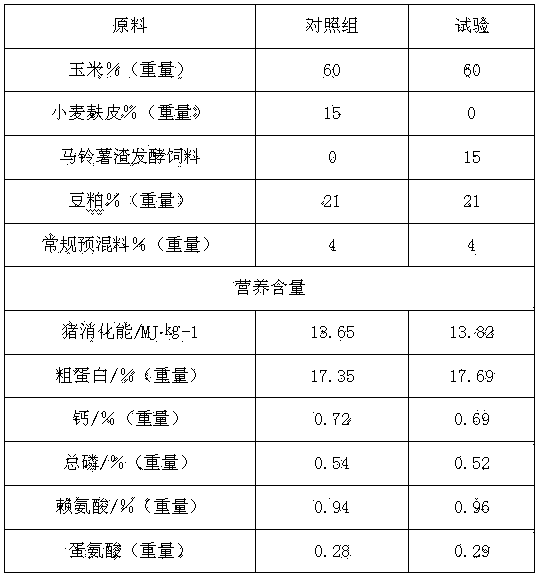

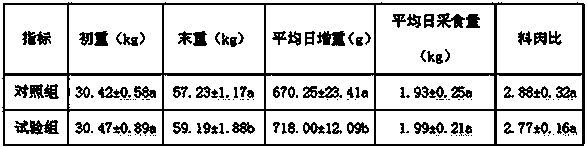

Examples

Embodiment 1

[0029] The following raw and auxiliary materials and reagents are used by weight: 160 grams of potato dregs, 20 grams of dried jujube powder, 20 grams of defatted rice bran, 3 grams of urea, 3 grams of ammonium sulfate, 1.2 grams of potassium dihydrogen phosphate, and 1 gram of magnesium sulfate.

[0030] Preparation method: After weighing the above-mentioned raw materials and reagents, put them into a pulverizer to pulverize them, and then put them into a mixer to mix evenly to make a fermentation substrate, and then use Bacillus subtilis, yeast, Aspergillus niger and Lactobacillus plantarum The bacterial liquid is a combined fermentation strain bacterial liquid, wherein the bacterial liquid concentrations of Bacillus subtilis, Saccharomyces spp., Aspergillus niger and Lactobacillus plantarum are all 1×10 6 pcs / ml, the combined fermentation strain bacterial liquid is formed by mixing the bacterial liquid of Bacillus subtilis, yeast S. niger, and Lactobacillus plantarum accordi...

Embodiment 2

[0032] The following raw and auxiliary materials and reagents are used by weight: 160 grams of potato dregs, 20 grams of dried date powder, 20 grams of defatted rice bran, 3 grams of urea, 1.5 grams of ammonium sulfate, 1.2 grams of potassium dihydrogen phosphate, and 1 gram of magnesium sulfate.

[0033]Preparation method: The difference from Example 1 is that the bacterial liquid of the combined fermentation strain is composed of the bacterial liquid of Bacillus subtilis, yeast, Aspergillus niger and Lactobacillus plantarum according to the volume ratio of 1:2:2:2 It is formed by mixing; the fermentation substrate and the combined fermentation strain liquid are uniformly mixed in a weight ratio of 1:1.2.

Embodiment 3

[0035] The following raw materials and reagents are used by weight: 150 grams of potato dregs, 30 grams of dried jujube powder, 20 grams of defatted rice bran, 3 grams of urea, 3 grams of ammonium sulfate, 1.2 grams of potassium dihydrogen phosphate, and 1 gram of magnesium sulfate.

[0036] Preparation method: The difference from Example 1 is that the combined fermentation strain bacterial liquid is composed of bacterial liquids of Bacillus subtilis, yeast, Aspergillus niger and Lactobacillus plantarum in a volume ratio of 1:1:1:1 It is formed by mixing; the fermentation substrate and the combined fermentation strain liquid are uniformly mixed in a weight ratio of 1:1.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com