Tomato Leaf Extract and Its Application in Cosmetics

A technology for tomato leaves and extracts is applied in the field of cosmetics to achieve the effects of expanding the development and application fields, the extraction process is simple and easy to operate, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

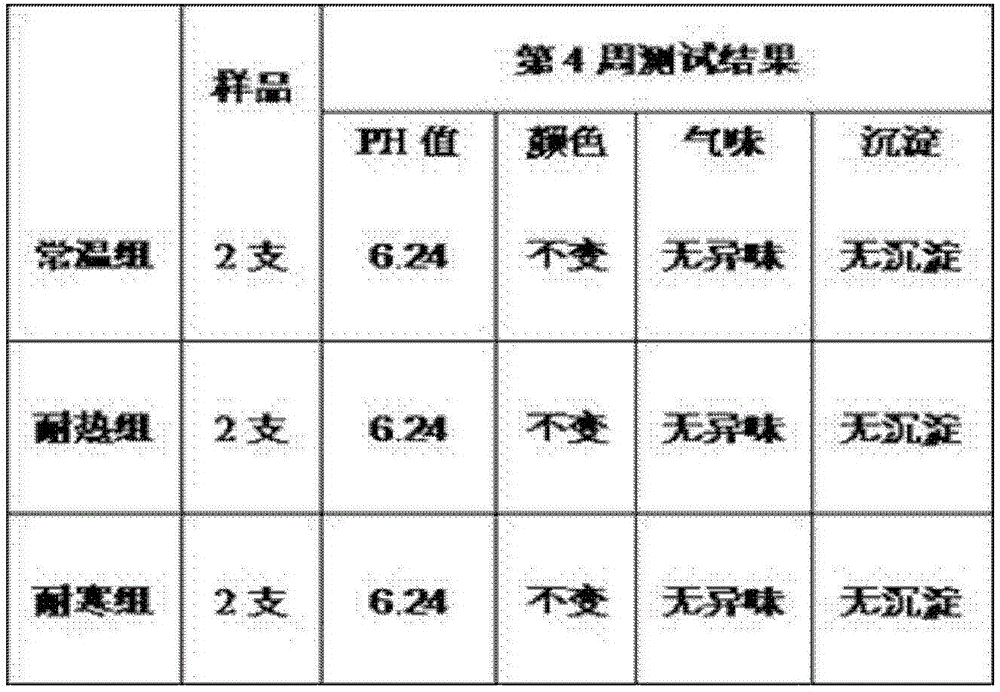

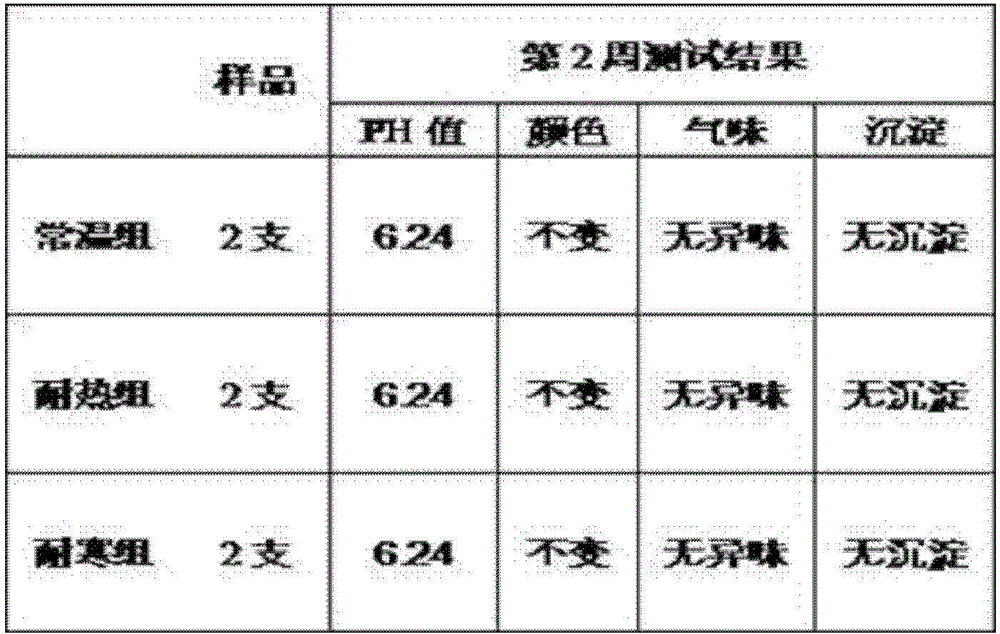

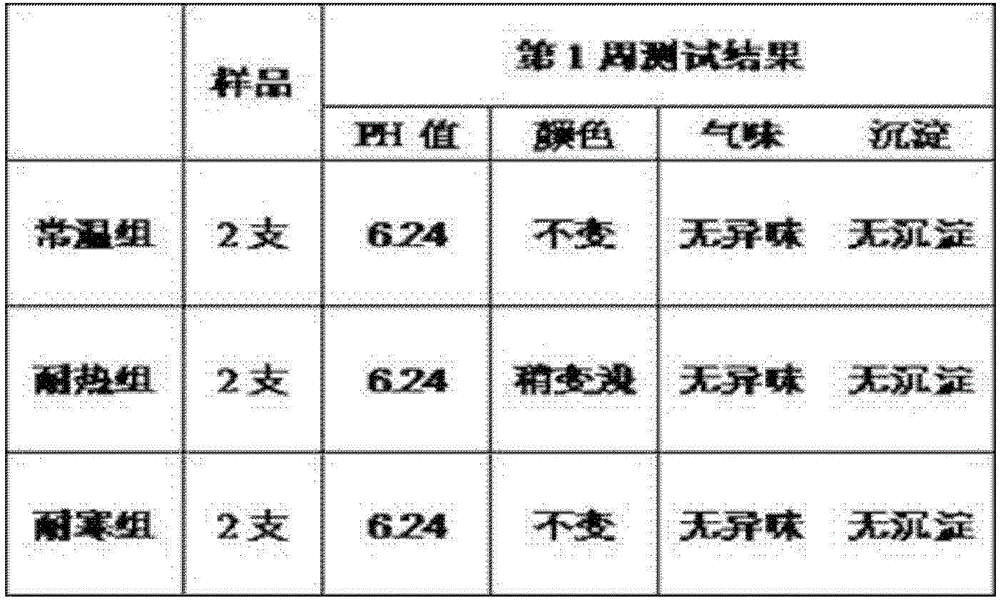

Image

Examples

Embodiment 1

[0025] A preparation method of tomato leaf extract, comprising the following steps:

[0026] Step 1, crushing: crushing the dried tomato leaves to 100 mesh;

[0027] Step 2, crude extraction: prepare an aqueous solution of sodium bisulfite with a mass fraction of 0.1%, and then add ethanol until the volume concentration of ethanol is 30%, to obtain a solution. Add the solution to the crushed tomato leaf material in step 1, the mass ratio of the crushed material to the solution is 1:10-1:20, extract at 60-90°C for 4-6 hours, and repeat the extraction three times;

[0028] Step 3, filter and dry: cool the crude extract in step 2 to 20-30°C, filter out insoluble matter with a filter cloth of 1000-2000 mesh, and concentrate under reduced pressure to 1 / 5 to 1 / 10 of the volume of the extract in step 2 , and then vacuum-dried to obtain dry matter;

[0029] Step 4. Dissolving and refining: add the dry matter obtained in step 3 to 1,3-butanediol, the mass volume ratio of dry matter t...

Embodiment 2

[0031] A preparation method of tomato leaf extract, comprising the following steps:

[0032] Step 1, crushing: crushing the dried tomato leaves to 100 mesh;

[0033] Step 2, crude extraction: prepare an aqueous solution of sodium bisulfite with a mass fraction of 0.3%, and then add ethanol until the volume concentration of ethanol is 50%, to obtain a solution. Add the solution to the crushed tomato leaf material in step 1, the mass ratio of the crushed material to the solution is 1:10-1:20, extract at 60-90°C for 4-6 hours, and repeat the extraction three times;

[0034] Step 3, filter and dry: cool the crude extract in step 2 to 20-30°C, filter out insoluble matter with a filter cloth of 1000-2000 mesh, and concentrate under reduced pressure to 1 / 5 to 1 / 10 of the volume of the extract in step 2 , and then vacuum-dried to obtain dry matter;

[0035] Step 4. Dissolving and refining: add the dry matter obtained in step 3 to 1,3-butanediol, the mass volume ratio of dry matter t...

Embodiment 3

[0037] A preparation method of tomato leaf extract, comprising the following steps:

[0038] Step 1, crushing: crushing the dried tomato leaves to 100 mesh;

[0039] Step 2, crude extraction: prepare an aqueous solution of sodium bisulfite with a mass fraction of 0.5%, and then add ethanol until the volume concentration of ethanol is 40%, to obtain a solution. Add the solution to the crushed tomato leaf material in step 1, the mass ratio of the crushed material to the solution is 1:10-1:20, extract at 60-90°C for 4-6 hours, and repeat the extraction three times;

[0040] Step 3, filter and dry: cool the crude extract in step 2 to 20-30°C, filter out insoluble matter with a filter cloth of 1000-2000 mesh, and concentrate under reduced pressure to 1 / 5 to 1 / 10 of the volume of the extract in step 2 , and then vacuum-dried to obtain dry matter;

[0041] Step 4. Dissolving and refining: add the dry matter obtained in step 3 to 1,3-butanediol, the mass volume ratio of dry matter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com