A pumice-based lightweight self-compacting ultra-high performance concrete and its preparation method

An ultra-high-performance, self-compacting technology, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of large discreteness, reduced mechanical properties of concrete, and high brittleness, so as to broaden the application field and alleviate the environment and ecology Problems, effects of good homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

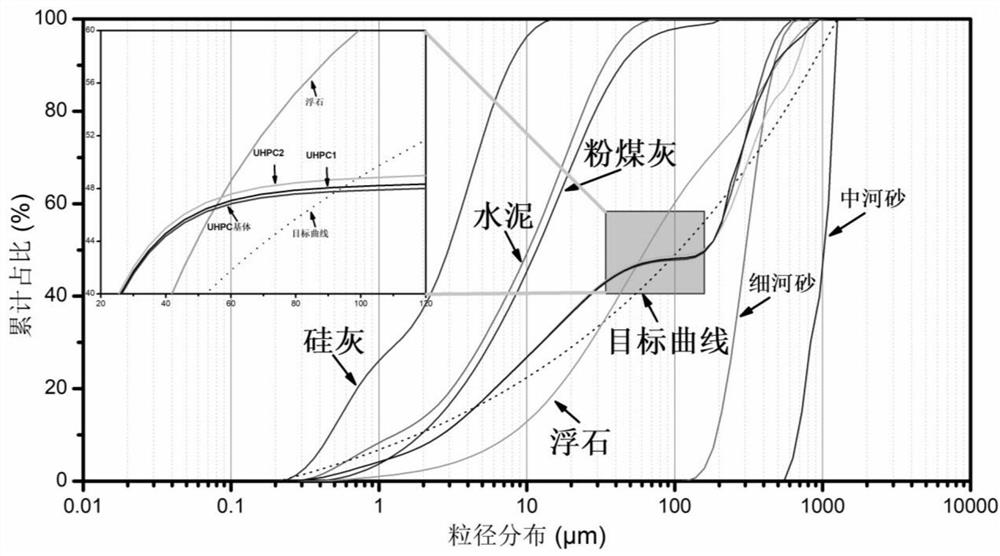

[0044] A pumice-based lightweight self-compacting ultra-high performance concrete, which consists of powder, aggregate and water reducer, the powder is P152.5 cement (Huaxin Cement Co., Ltd., Huangshi), Class I fly ash (Huaneng Yangluo Power Plant, Wuhan), micro-silica fume (Donglanxing Technology Development Co., Ltd., Chengdu), aggregates are natural river sand (Wuhan) and water-absorbing pumice (Changbai Mountain), and the water-reducing agent is polycarboxylic acid-type water-reducing agent ( Jiangsu Subote New Material Co., Ltd., Nanjing); among them, the particle size distribution of river sand is 0.6mm-1.5mm, the particle size distribution of water-absorbing pumice is 0-0.6mm, the porosity is 35%-55%, and the water-absorbing The rate is 35%; before water absorption treatment, the pumice density is 0.6kg / m 3 ~1.1kg / m 3 .

[0045] The preparation method of the above-mentioned pumice-based lightweight self-compacting ultra-high performance concrete, the specific steps ar...

Embodiment 2

[0064] The difference between Example 2 and Example 1 is that the particle size distribution of the river sand is 0-0.6mm; the particle size distribution of the water-absorbing pumice is 0-1.3mm, and the particle size of the pumice is 0-0.6mm in the total mass of the pumice 85%, the pumice water absorption rate is 40%, and the volume fraction of pumice replacing river sand is 95% to 99%; other related raw materials used, design, preparation and testing methods are consistent with embodiment 1.

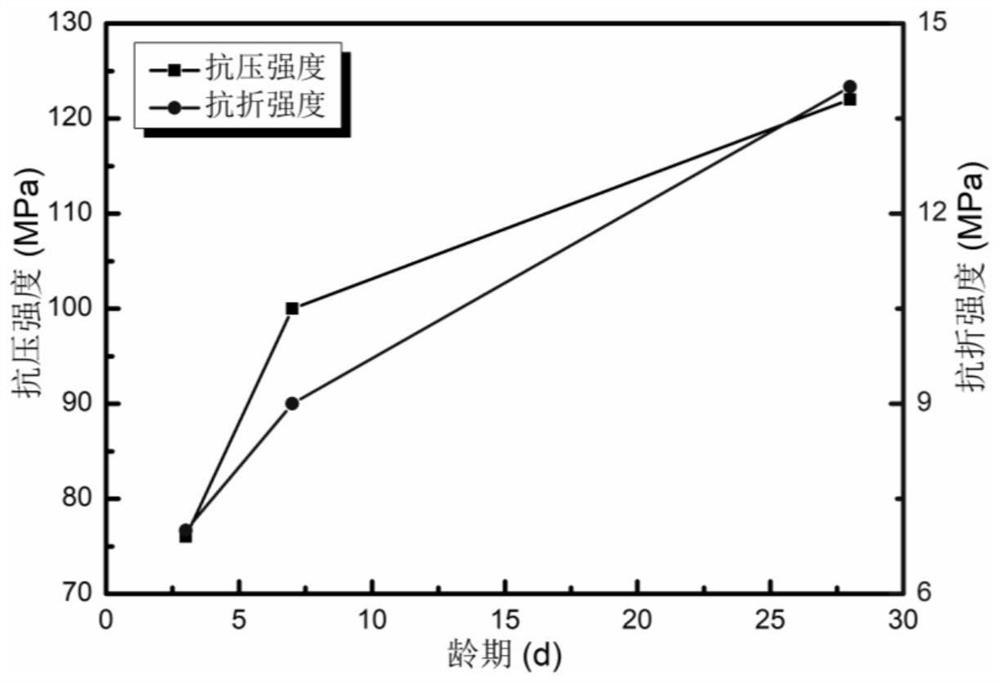

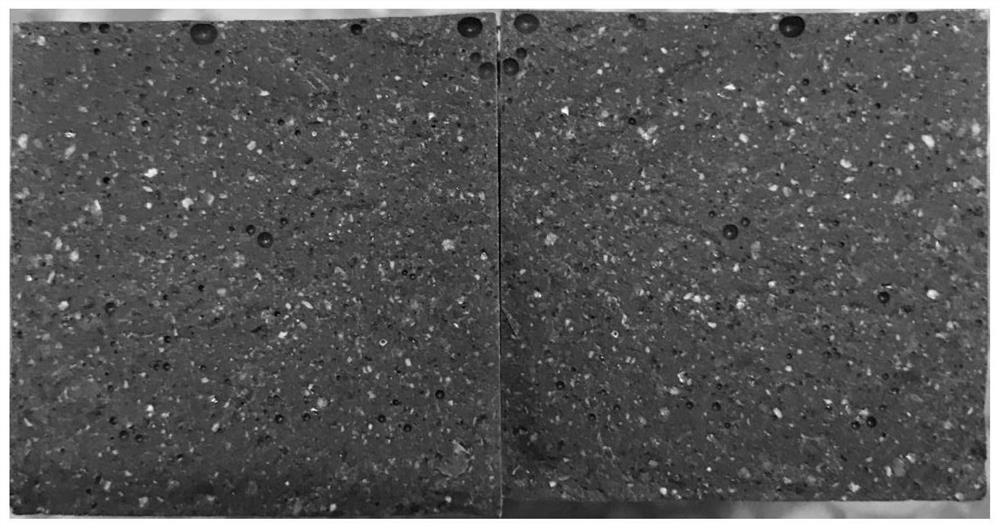

[0065] The mixing ratio of UHPC2 prepared in Example 2 is shown in Table 4. The performance of UHPC2 fresh slurry is shown in Table 5, the durability test results of UHPC2 specimens are shown in Table 6, and the development of mechanical properties is shown in Table 5. Figure 4 , the cross-sectional morphology of hardened cement stone is shown in Figure 5 .

[0066] Table 4 UHPC2 mix ratio (kg / m 3 )

[0067]

[0068] Table 5 UHPC2 fresh slurry properties

[0069]

[0070] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com