Application of multielement class-D dry powder extinguishing agent in extinguishment of metallic magnesium and metallic sodium fires

A technology of dry powder fire extinguishing agent and metal magnesium, which is applied in fire rescue and fire prevention equipment to achieve the effects of fast cooling, good electrical insulation and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

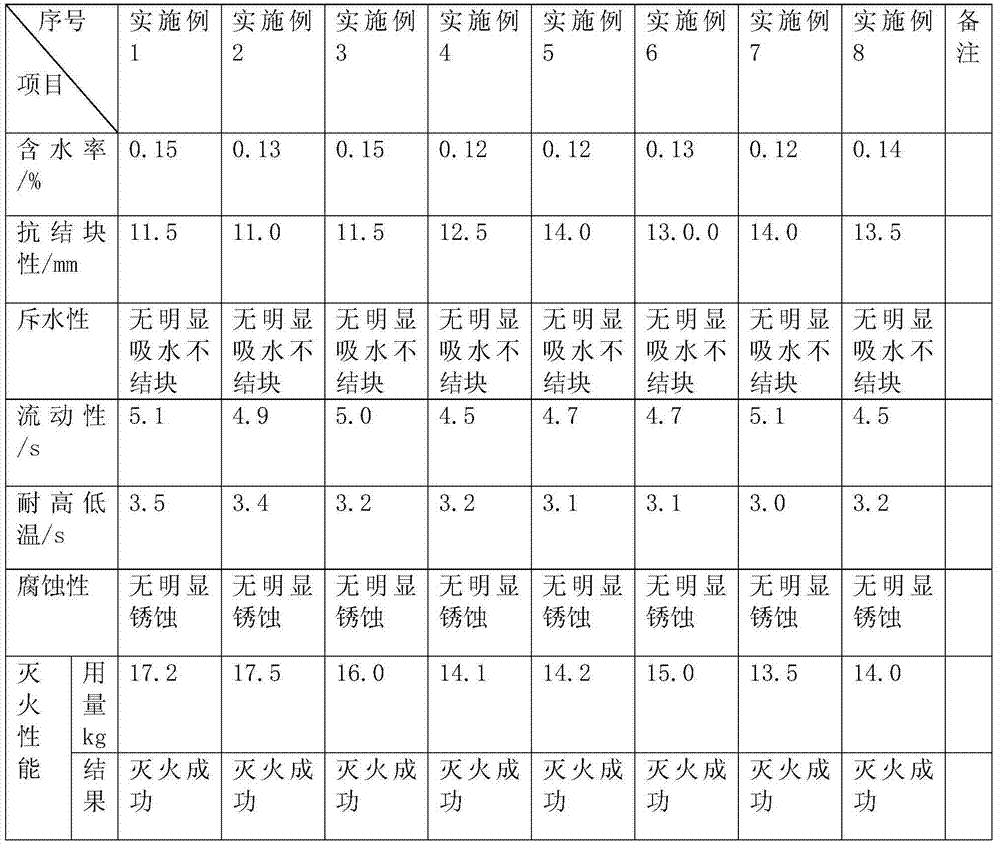

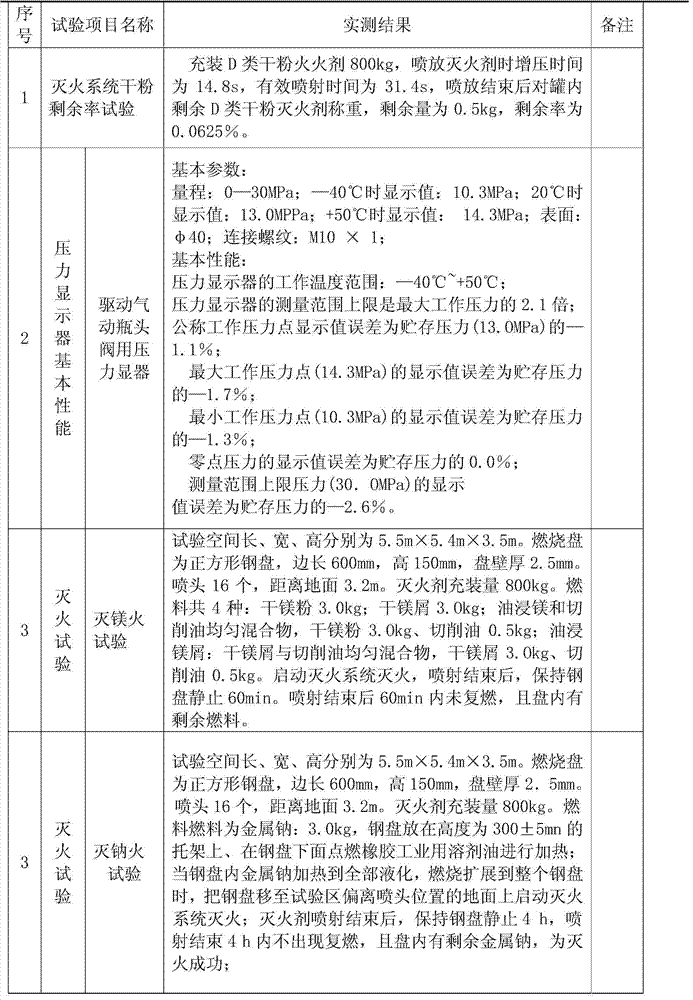

Examples

Embodiment 1

[0045] The used blocking agent hydrophobic silica, sodium silicate, kaolin or zeolite is commercially available, and its particle size is 10-100 μm;

[0046] The filler potassium chloride used, diatomaceous earth, talcum powder or calcium carbonate are commercially available, and its particle size is 10~100 μ m;

[0047] The catalyst starch, cellulose or pentaerythritol used are commercially available, and the particle size is 10-20 μm.

[0048] Raw material consumption

[0049] Modified sodium chloride 50kg

[0050] Hydrophobic silica 30kg

[0051] Potassium chloride 10kg

[0052] Starch 5kg

[0053] The hydrophobic silica used is chemically modified by dimethyldichlorosilane monomer, or physically modified by mixing with polymethylsiloxane;

[0054] Its preparation method steps are as follows:

[0055] ⑴Add the silica powder to the modified sodium chloride and mix evenly in the airflow with a pressure of ≥0.5MPa, and set aside;

[0056] (2) Add the remaining fillers a...

Embodiment 2

[0070] Raw material consumption

[0071] Modified sodium chloride 40kg

[0073] Diatomaceous earth 5kg

[0074] Starch 1kg

[0075] All the other are with embodiment 1.

Embodiment 3

[0077] Raw material consumption

[0078] Modified sodium chloride 50kg

[0079] Kaolin 30kg

[0080] Talc powder 10kg

[0081] Cellulose 5kg

[0082] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com