Antibacterial activated carbon composite material and preparation method thereof

A composite material and activated carbon technology, applied in the field of material engineering, can solve the problems of safety and environmental pollution, poor heat resistance and stability, etc., and achieve good antibacterial effect, high TiO2 content, antibacterial effect and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

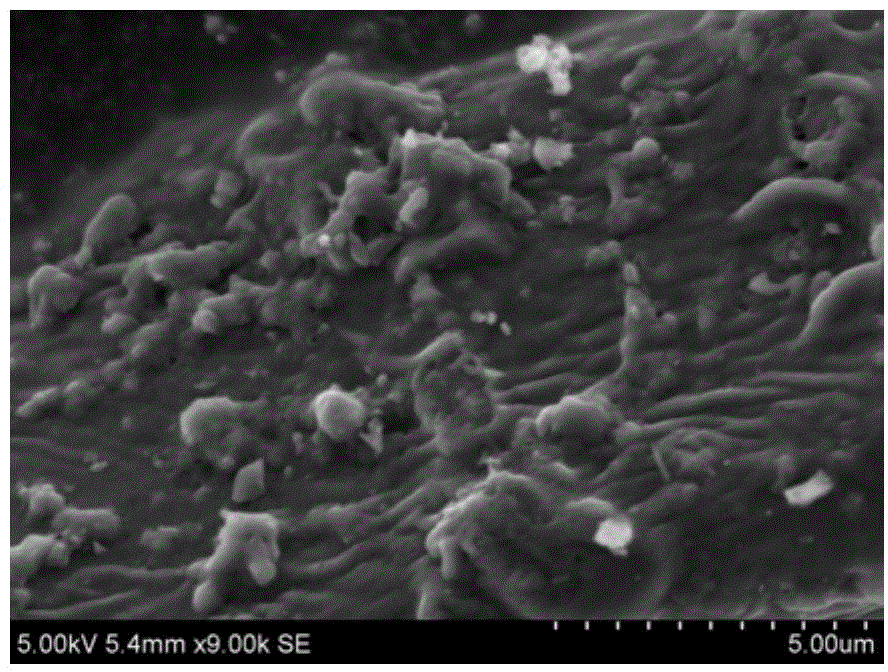

Image

Examples

Embodiment 1

[0033] Embodiment 1 antibacterial activated carbon composite material and preparation method thereof

[0034] 1. Preparation and pretreatment of activated carbon

[0035] Treat the fiberboard into a long specimen of 10cm×3cm×0.9cm, and carbonize it at 600°C for 1 hour to obtain a carbonized product; crush the carbonized product into small pieces of 10mm×10mm×3mm, and heat it at 700°C with a water vapor flow rate of 4.84g Activated carbon was activated for 1 h under the condition of 1 / min; the activated carbon was sieved with a 120-mesh sieve, and dehydrated at a constant temperature of 110 ° C for 12 h.

[0036] 2. Preparation of mixed system of titanium alkoxide, solvent and acid

[0037]After adding n-butyl titanate and nitric acid to isopropanol, stir continuously until a colloidal solution with fine particles and uniform dispersion is formed to obtain a mixed system, wherein the volume ratio of n-butyl titanate to isopropanol is 1 :4 (that is, the molar ratio is 1:18), t...

Embodiment 2

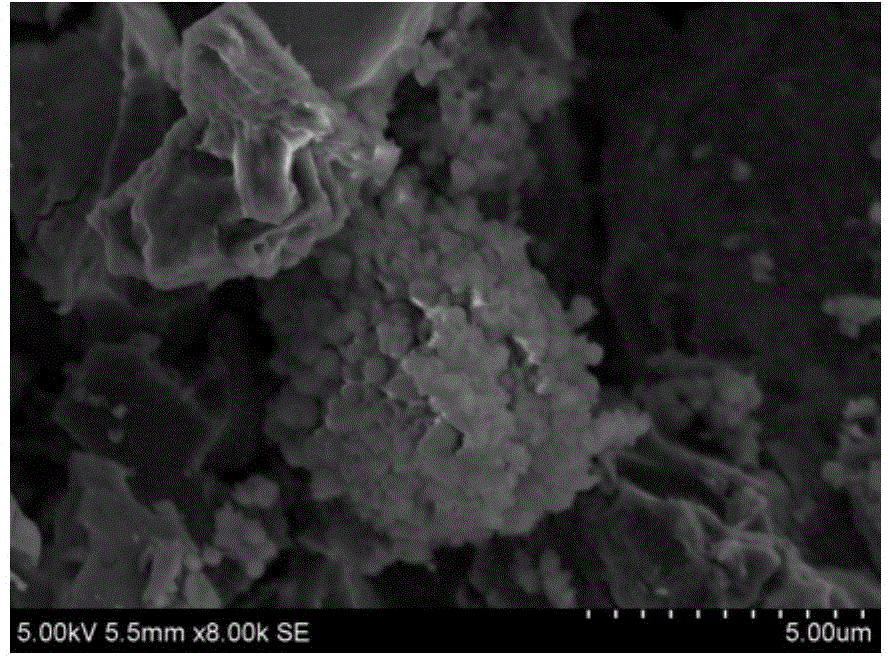

[0043] Embodiment 2 antibacterial activated carbon composite material and preparation method thereof

[0044] Loading TiO by Sol-Gel Method 2 In the step, 0.5g activated carbon is put into the mixing system to prepare TiO 2 / activated carbon composite material, all the other are identical with embodiment 1.

Embodiment 3

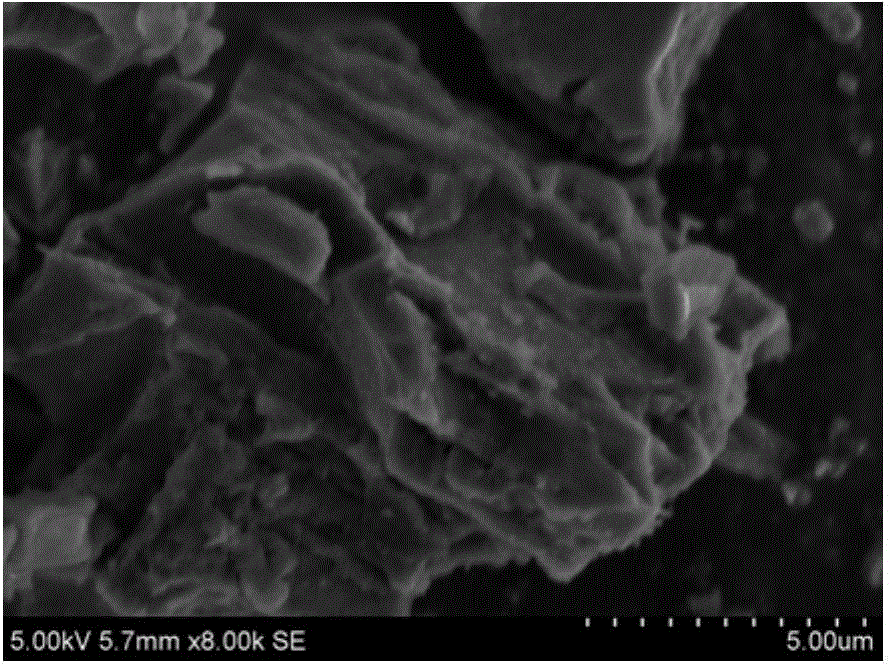

[0045] Embodiment 3 antibacterial activated carbon composite material and preparation method thereof

[0046] Loading TiO by Sol-Gel Method 2 In the step, 2g activated carbon is put into the mixing system to prepare TiO 2 / activated carbon composite material, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com