Anion-cation exchange resin cleaning agent

An anion-cation exchange and cleaning agent technology, which is applied in the direction of ion exchange bed cleaning/flushing, ion exchange, ion exchange regeneration, etc., can solve the problems of harmful resin, iron, suspended solids and other resin pollution, cumbersome cleaning process, etc., to achieve saving The effect of power resources, increasing water production, and reducing the number of sewage discharges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First add 759 kg of water to the reaction kettle, heat the water temperature to 30 degrees, add 38 kg of disodium edetate, 23 kg of acrylic acid / sulfonic acid / acrylamide copolymer and 45 kg of polyacrylic acid, stir for 30 minutes, then add iso Construct 135 kg of decanol polyoxyethylene ether, stir for 60 minutes, and cool to 25 degrees to get the finished product.

[0030] The prepared cleaning agent was subjected to a cleaning test.

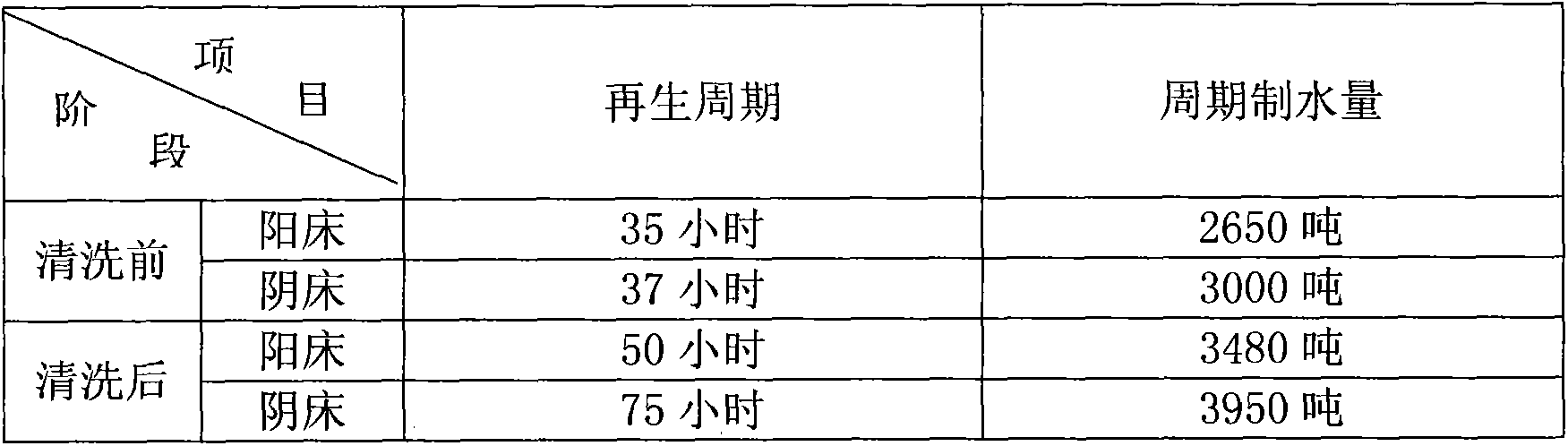

[0031] Before cleaning, first flush the resin bed as necessary, and then add the prepared resin cleaning agent to the ion exchanger according to 5-15% of the volume of the ion exchange resin through the injector, and then inject purified water into the ion exchanger. Finally, rinse with compressed air. During the rinsing process, scrub with air pressure, then stand still, and do it alternately; ;Wait until the foam is obviously reduced, directly enter the purified water to rinse, and stop when there is no foam; after the rinse is compl...

Embodiment 2

[0038] First add 741 kilograms of water to the reactor, heat the water temperature to 30 degrees, add 25 kilograms of phosphonobutane carboxylic acid, 18 kilograms of acrylic acid / sulfonic acid / acrylamide copolymer and 34 kilograms of polymaleic acid, stir for 30 minutes, and then Add 182 kg of polyoxyethylene polyoxypropylene block polyether, stir for 60 minutes, and cool to 25 degrees to obtain the finished product.

[0039] The prepared cleaning agent was subjected to a cleaning test.

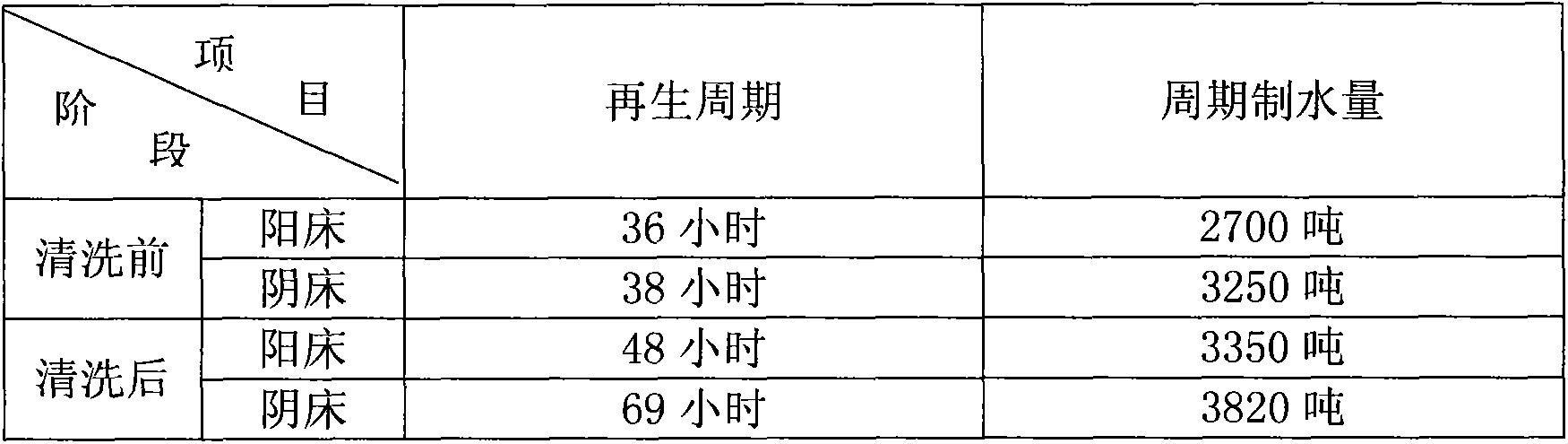

[0040] Before cleaning, first flush the resin bed as necessary, and then add the prepared resin cleaning agent to the ion exchanger according to 5-15% of the volume of the ion exchange resin through the injector, and then inject purified water into the ion exchanger. Finally, rinse with compressed air. During the rinsing process, scrub with air pressure, then stand still, and do it alternately; ;Wait until the foam is obviously reduced, directly enter the purified water to rinse, and stop w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com