Optimization method of precession machining trajectory of mold pneumatic grinding wheel based on 3D boundary extraction

A technology of boundary extraction and pneumatic grinding wheel, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to directly obtain model boundary line data, and achieve simple and reliable calculation process, easy programming, and low operation difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

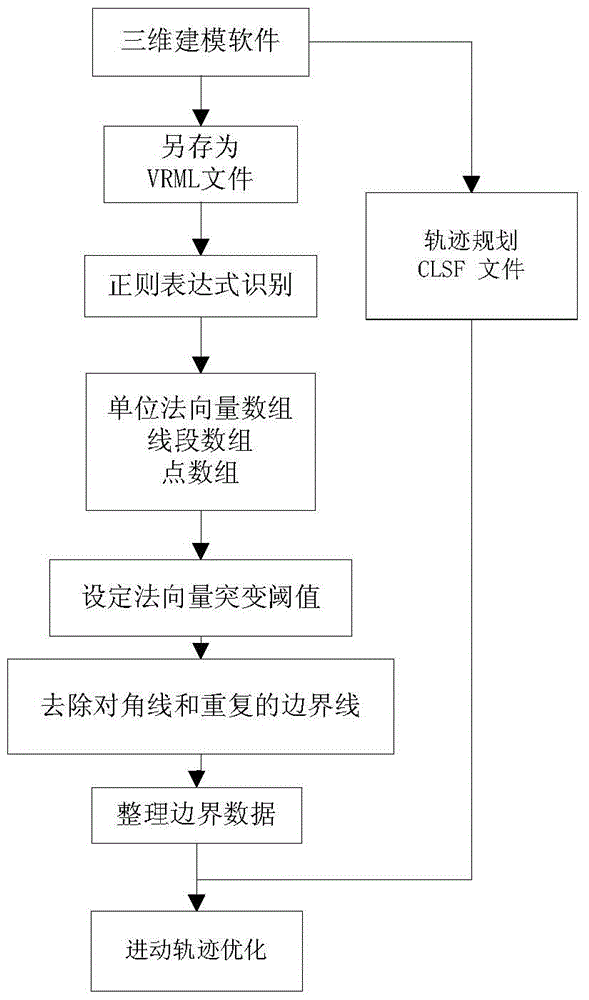

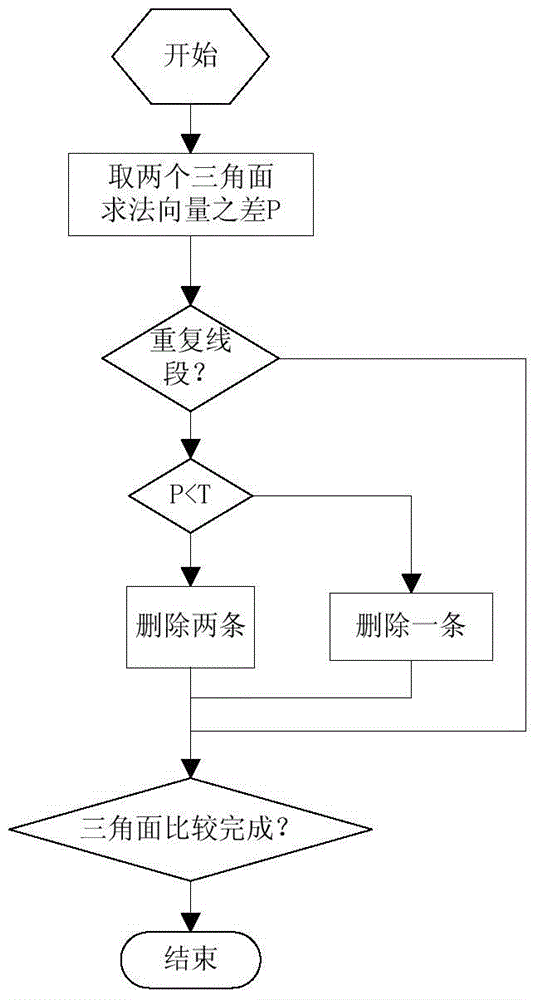

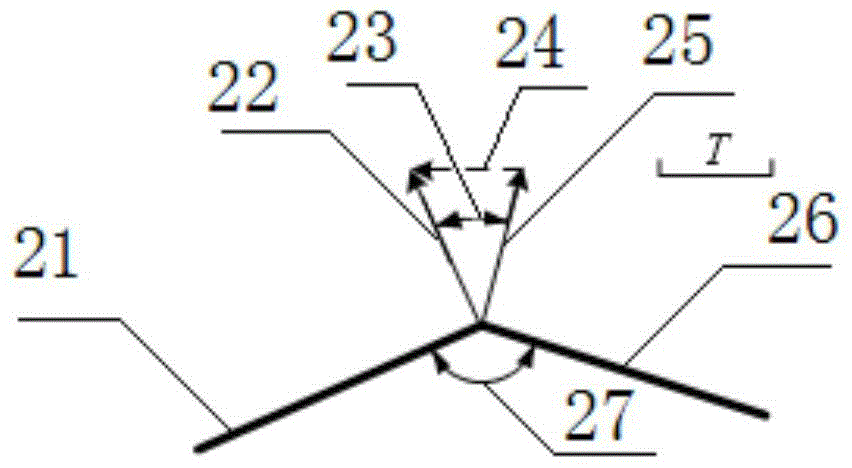

[0029] refer to Figure 1 to Figure 8 , and taking the hexagonal prism to extract the boundary line and the mold surface trajectory optimization as examples, a method for optimizing the machining trajectory of mold pneumatic grinding wheel precession based on three-dimensional boundary extraction is provided. The trajectory optimization method includes the following steps:

[0030] The first step is to build a mold model through 3D software, plan the trajectory of the model’s machining surface, and save it in the CLSF file format with the file extension cls; at the same time, save the model in the VRWL file format with the file extension wrl.

[0031] The second step is to read the VRML file. The three-dimensional graphics information described in the file is mainly composed of the following four parts: coordinate point (Coordinate point), point normal vector (Normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com